builderchad

Established Member

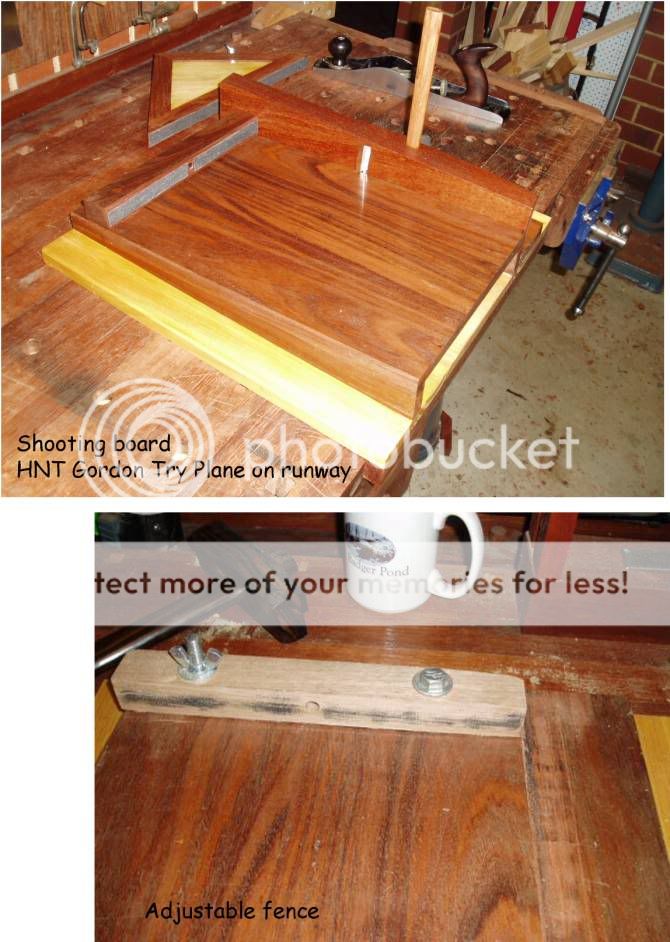

I am in the process of making myself a shooting board from two nice and stable pieces of .5" MDF. I will use two pieces of beech as well. One to hold the work piece against (the sticky up bit) and the other as a hook under the shooting board.

I have a lovely book on making tools that also covers making shooting boards and the guy is adamant that the top piece of wood that the workpiece rests on is no thicker than the gap between the plane blade and the plane cheek so the blade does not come into contact with the wood. As such he goes on to say that each shooting board should be made specifically for a particular plane and no other because this gap is different on every plane.

In my evening woodworking class (which is now over so I can't ask my teacher) there was a shooting board whose two main boards were 1/2 inch ply. It worked very well and the plane blade definately overlapped the board that the workpiece rested on and so could potentially cut into it.

So, my question is this - do I ignore this advice and just use the two pieces of 1/2 inch MDF I have?

I have a lovely book on making tools that also covers making shooting boards and the guy is adamant that the top piece of wood that the workpiece rests on is no thicker than the gap between the plane blade and the plane cheek so the blade does not come into contact with the wood. As such he goes on to say that each shooting board should be made specifically for a particular plane and no other because this gap is different on every plane.

In my evening woodworking class (which is now over so I can't ask my teacher) there was a shooting board whose two main boards were 1/2 inch ply. It worked very well and the plane blade definately overlapped the board that the workpiece rested on and so could potentially cut into it.

So, my question is this - do I ignore this advice and just use the two pieces of 1/2 inch MDF I have?