Corneel

Established Member

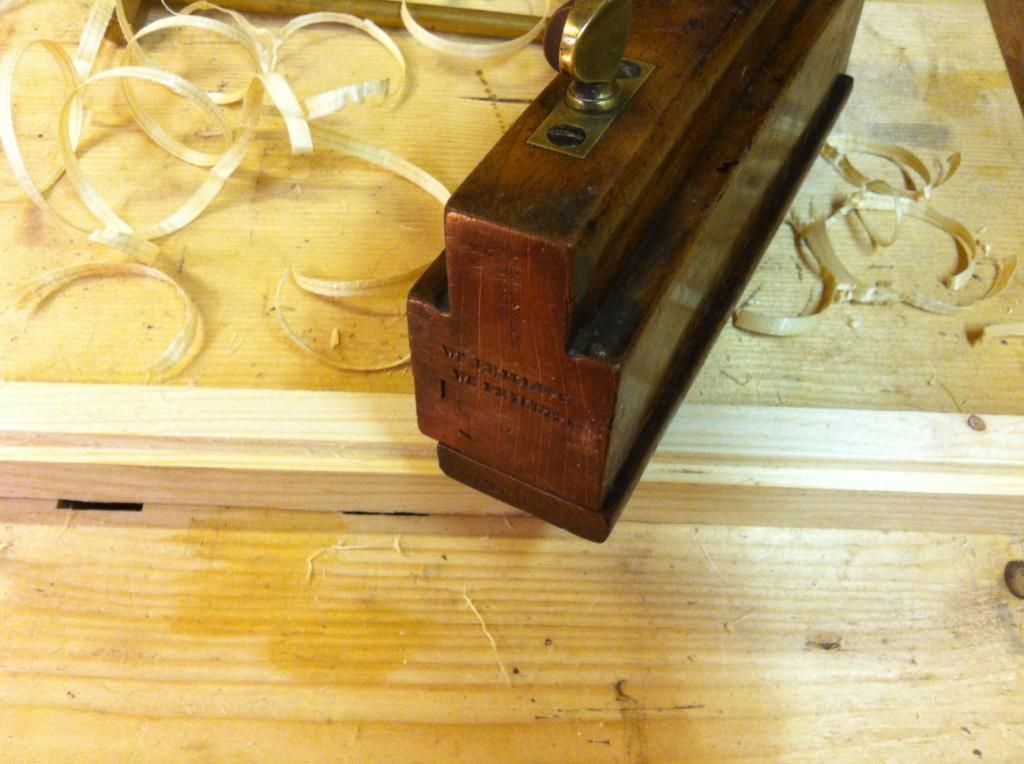

The fillester I bought lately cam with one original and one not so original screw to attach the fence. The not so original one, a countersunk screw, doesn't work at all. It was even pretty hard to get it out of the plane. The original also a problem, a completely buggered screwdriver slot.

So, what to do? I am looking for some ideas. I could of course run some helicoils into the body and use M8 machine screws instead. Not really very original looking. I could fill the holes, redrill them and turn some nice looking screws on the lathe. But I am hopeless at turning screwthreads, so I would have to use a die. And the coarsest one I have is a UNC thread. Using a big woodscrew? I don't know if I can find them with such a large head.

Any more ideas?

So, what to do? I am looking for some ideas. I could of course run some helicoils into the body and use M8 machine screws instead. Not really very original looking. I could fill the holes, redrill them and turn some nice looking screws on the lathe. But I am hopeless at turning screwthreads, so I would have to use a die. And the coarsest one I have is a UNC thread. Using a big woodscrew? I don't know if I can find them with such a large head.

Any more ideas?