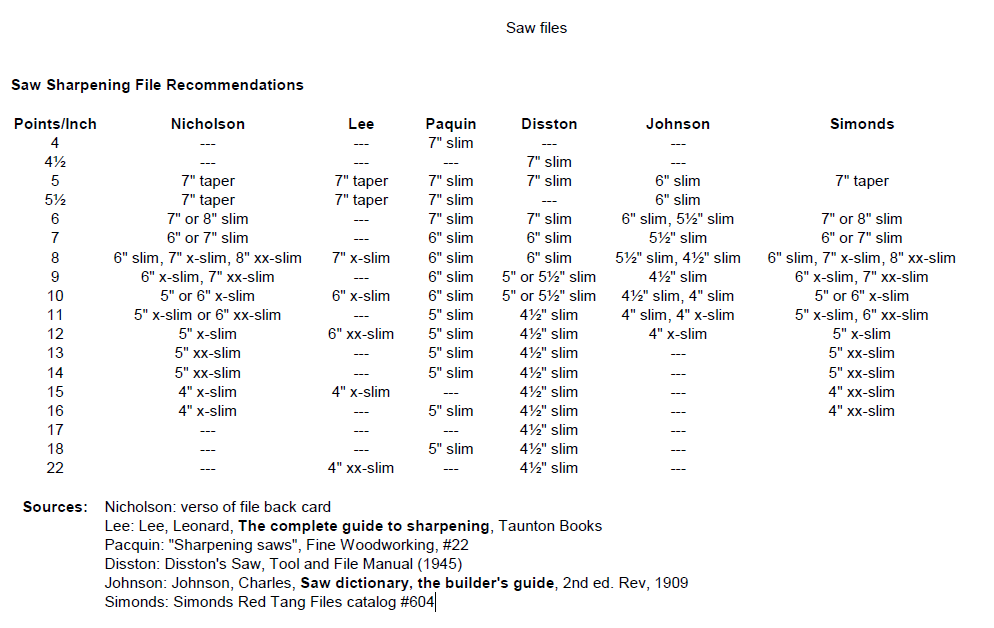

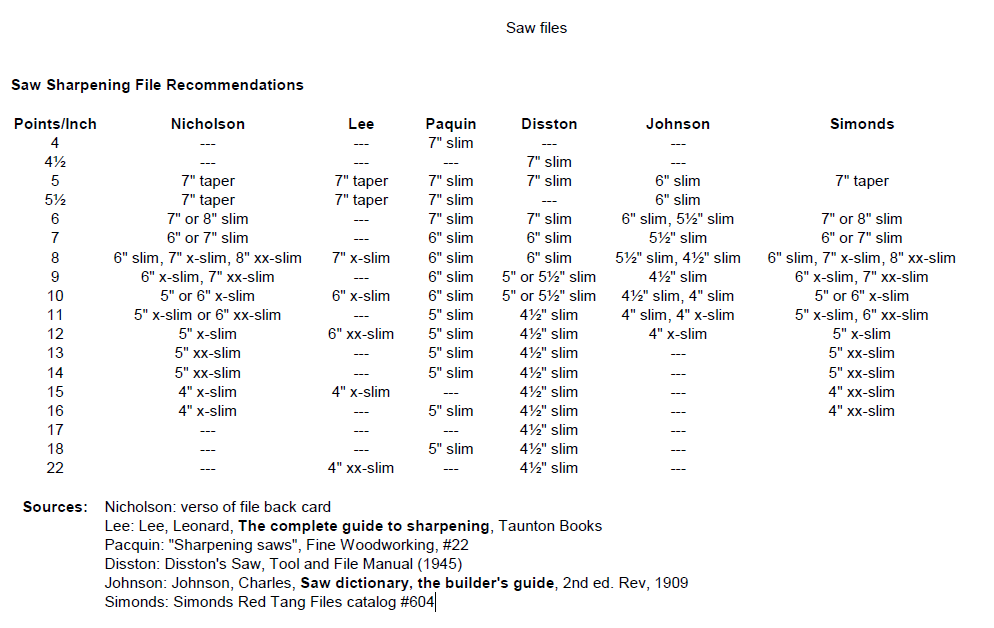

I'm sure I've come across other saw-file size charts, probably with more slightly different recommendations! I think it's probably best to regard them all as 'guidance' rather than 'absolute'.

I think Mike S pretty well nailed it by saying that a sawfile is best sized as about twice the filing depth, so that when one corner (and a bit less than half of the adjacent sides) are worn, the file can be turned and the next corner used without there being an overlapping worn bit on the sides. That way, you get three 'lives' out of the file and don't waste two corners.

It's probably best to have only about three or four sizes of file to hand to cover all saws, and as long as you avoid really silly combinations like using a needle file on a big rip saw, or a 7" regular to try filing a 16tpi dovetail saw, you should be OK using 'near enough' files. Too small won't do the whole job, too big leaves excessive gullets and obscures your sight of what you're doing, but a size or so up or down won't matter too much.

Another factor is what you can buy. If the charts say 5" extra slim, but you can only buy 6" double-extra slim, don't sweat it. It'll do.

Don't forget that for topping (jointing) the toothline, you'll need a flat file. A smooth cut mill saw file is usually recommended for this, but almost any flat or hand smooth file will serve. About 8" is a convenient length, but a bit longer won't harm.

One last tip is to file slowly. Saw steel is hard, and won't respond well to filing at the same speed something like brass will. A 6" saw-file should take near enough a full second to travel it's full length through a saw blade - you should be able to see the filings coming off. Faster than that will mean the file 'skates' across the hard steel, taking off few filings but dulling the teeth of the file quickly.