DavidE

Established Member

Hi there,

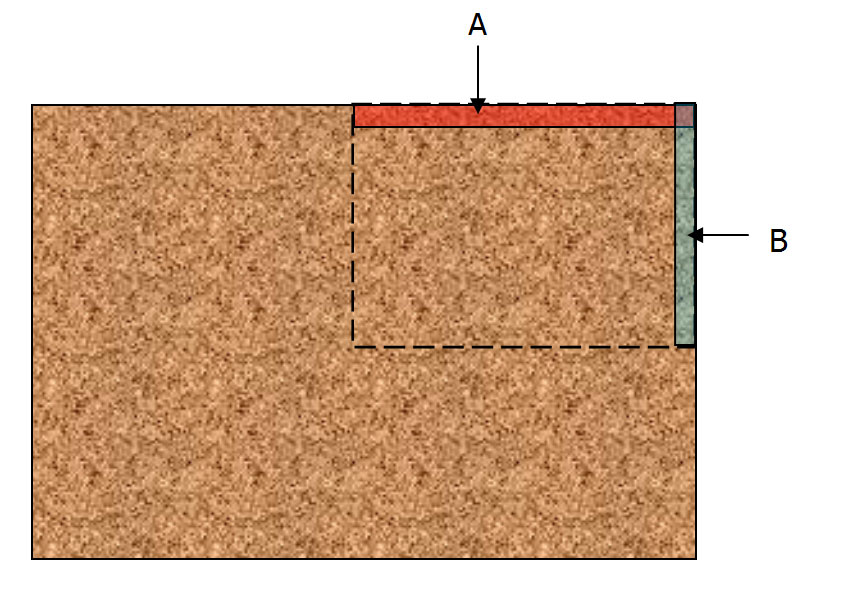

I've got some rebates to cut for some door frames. I've cut similar ones in the past and had some excellent results and other times there has been a bit of feathering (also called spelching maybe? along one of the edges. I have never managed to come up with the definitive way of avoiding this. I imagine this will be heavily dependant on the direction of grain of the wood too and on a board where this is changing it can be tricky.

So here's my question - which of the methods described below and in reference to the drawing is most reliable?

(I guess it's worth noting I do have a large diameter cutter that will cover the required size for the last pass.)

Method 1:

Take a scoring cut like A and keep going progressively deeper in a number of passes till the dotted line is reached.

Method 2

Take a scoring cut like B and keep going progressively widen a number of passes till the dotted line is reached.

Method 3

Take a scoring cut like B, then take the A scoring cut and continue with the A cuts till the dotted line.

Method 4

Same as 3 but after scoring following the B cuts.

Thanks, David

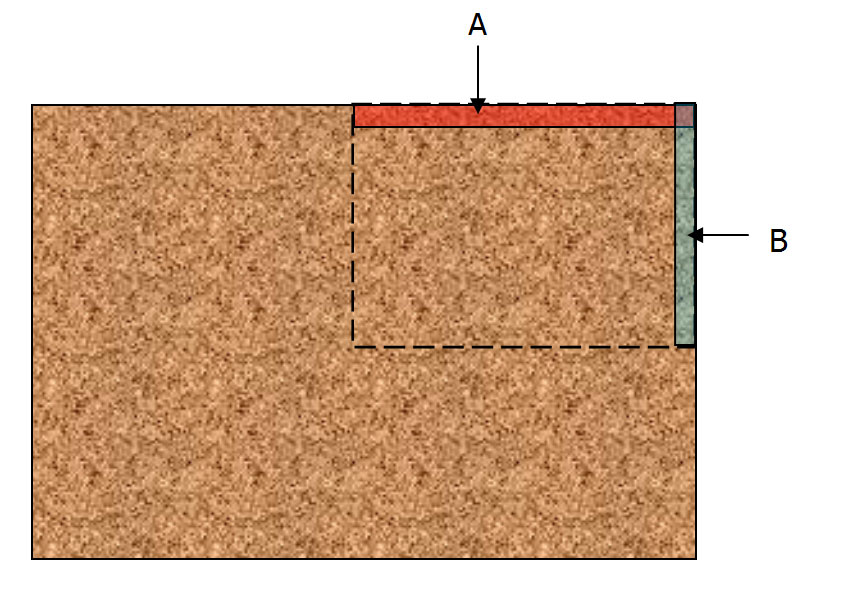

I've got some rebates to cut for some door frames. I've cut similar ones in the past and had some excellent results and other times there has been a bit of feathering (also called spelching maybe? along one of the edges. I have never managed to come up with the definitive way of avoiding this. I imagine this will be heavily dependant on the direction of grain of the wood too and on a board where this is changing it can be tricky.

So here's my question - which of the methods described below and in reference to the drawing is most reliable?

(I guess it's worth noting I do have a large diameter cutter that will cover the required size for the last pass.)

Method 1:

Take a scoring cut like A and keep going progressively deeper in a number of passes till the dotted line is reached.

Method 2

Take a scoring cut like B and keep going progressively widen a number of passes till the dotted line is reached.

Method 3

Take a scoring cut like B, then take the A scoring cut and continue with the A cuts till the dotted line.

Method 4

Same as 3 but after scoring following the B cuts.

Thanks, David