Philipp

Established Member

Hi folks,

For those who might be interested I'd like to share the results of my latest tests to use the router as a "scribing tool" for ripping.

Pictures tell more than words, so here they are:

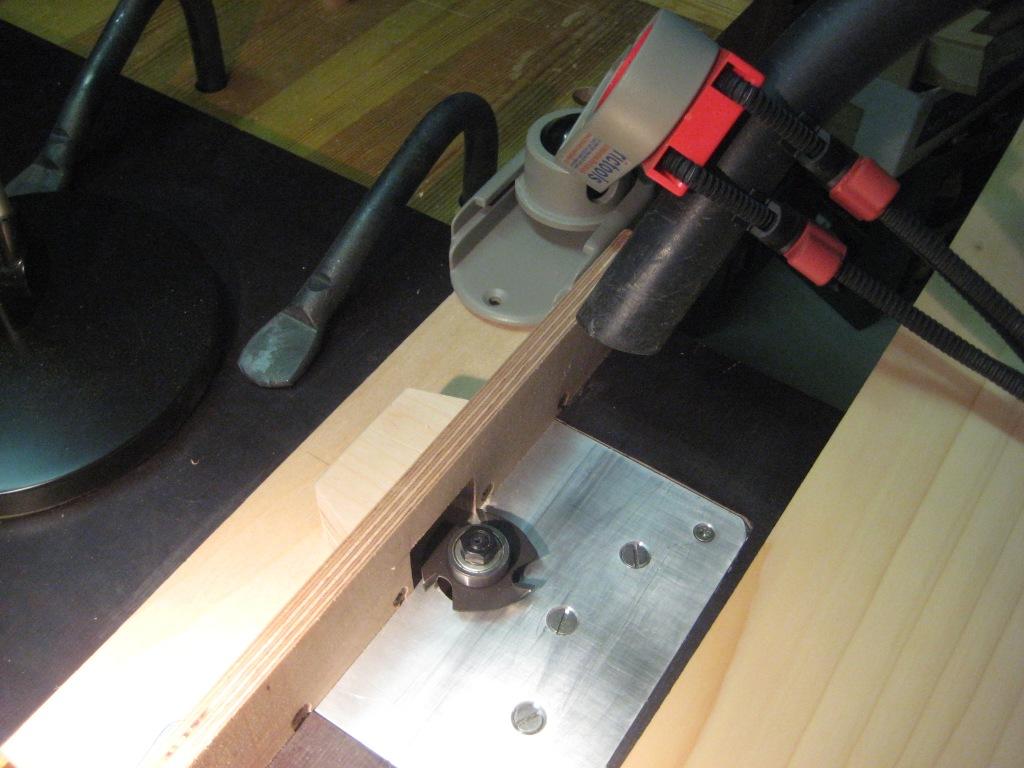

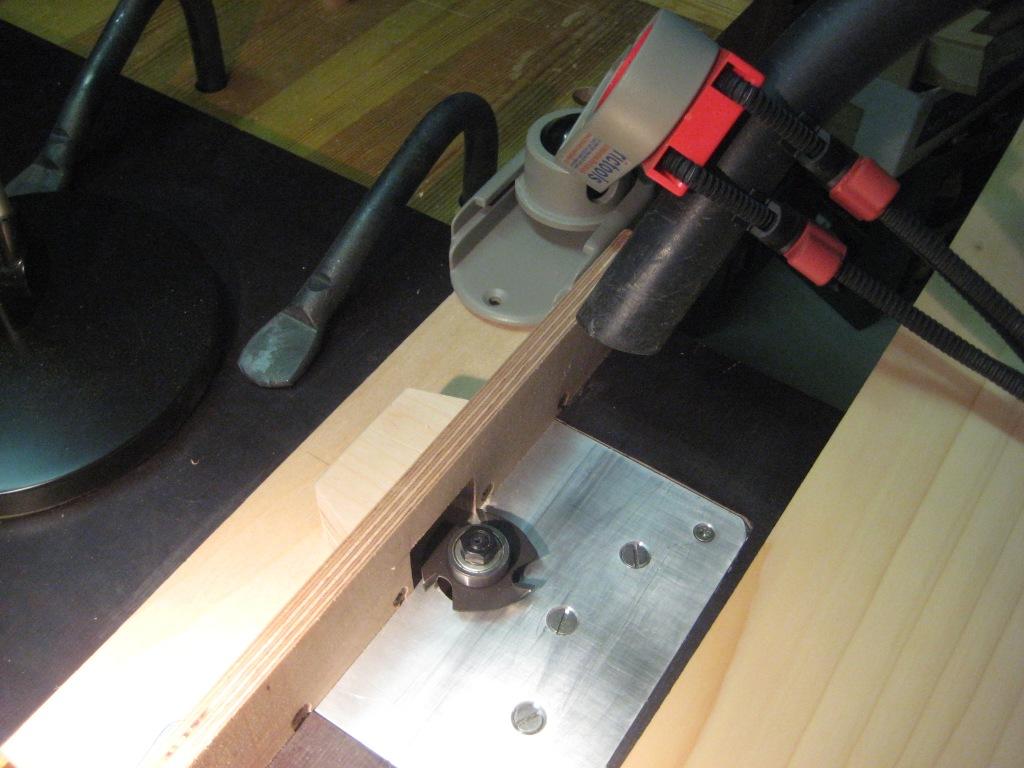

My primitive router table with a 1,6 mm slot cutter (http://www.fine-tools.com/scheibennutfraeser.html) mounted in my small router. The board of course was planed flat in order to have a reference surface:

The slot:

Using the slot as a guide for the saw:

Results:

Unfortunately, the board bent due to stress release after ripping questioning all the fuzz about precision et al.:

Works very fine for me and is worth the effort, particularly when I have to be economic with my wood and cannot allow the saw to wander.

Regards, Philipp

For those who might be interested I'd like to share the results of my latest tests to use the router as a "scribing tool" for ripping.

Pictures tell more than words, so here they are:

My primitive router table with a 1,6 mm slot cutter (http://www.fine-tools.com/scheibennutfraeser.html) mounted in my small router. The board of course was planed flat in order to have a reference surface:

The slot:

Using the slot as a guide for the saw:

Results:

Unfortunately, the board bent due to stress release after ripping questioning all the fuzz about precision et al.:

Works very fine for me and is worth the effort, particularly when I have to be economic with my wood and cannot allow the saw to wander.

Regards, Philipp