I need a bit of advice regarding rip fences.

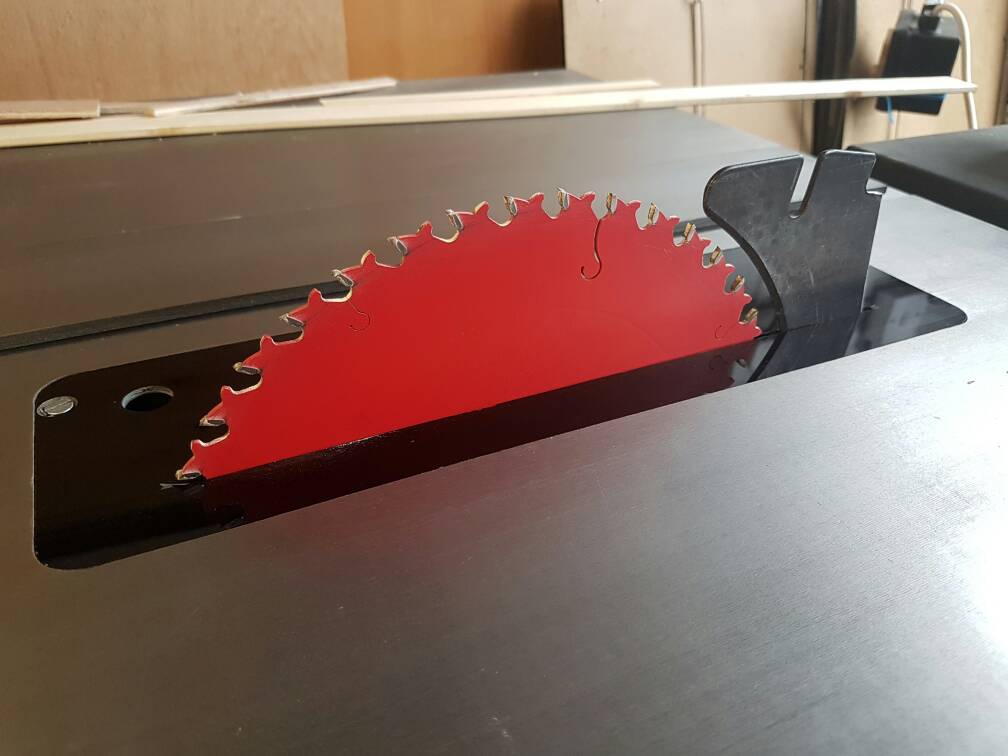

I've built my own table saw, using the Makita Site Saw as a base. The rip fence that came with the saw was rubbish so i bought the Axminster Rip Fence upgrade. All is basically well except for three aspects. Firstly the fence only reaches half way along the saw blade; secondly because of the base of the saw the fence doesn't slip easily across the table. Finally when cutting narrow < 20mm and thin (say 4mm) edging I'm finding the timber flaps as it passes the upward moving part of the blade, because there's nothing to hold it down. My old Triton had device built into the riving knife to prevent such behaviour.

I'd been thinking of extending the fence by adding ply or plastic to each side and using the t tracks on the fence to hold them in place. That would allow me to add a finger board after the blade to hold down the timber In principle I could add plastic to the underside too. On the other hand having a short fence means the timber has somewhere to go after first contact with the blade.

Any advice gratefully received.

I've built my own table saw, using the Makita Site Saw as a base. The rip fence that came with the saw was rubbish so i bought the Axminster Rip Fence upgrade. All is basically well except for three aspects. Firstly the fence only reaches half way along the saw blade; secondly because of the base of the saw the fence doesn't slip easily across the table. Finally when cutting narrow < 20mm and thin (say 4mm) edging I'm finding the timber flaps as it passes the upward moving part of the blade, because there's nothing to hold it down. My old Triton had device built into the riving knife to prevent such behaviour.

I'd been thinking of extending the fence by adding ply or plastic to each side and using the t tracks on the fence to hold them in place. That would allow me to add a finger board after the blade to hold down the timber In principle I could add plastic to the underside too. On the other hand having a short fence means the timber has somewhere to go after first contact with the blade.

Any advice gratefully received.