Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 76

Just when I was beginning to get really frustrated by eBay recently, I finally did get something for a reasonable price:

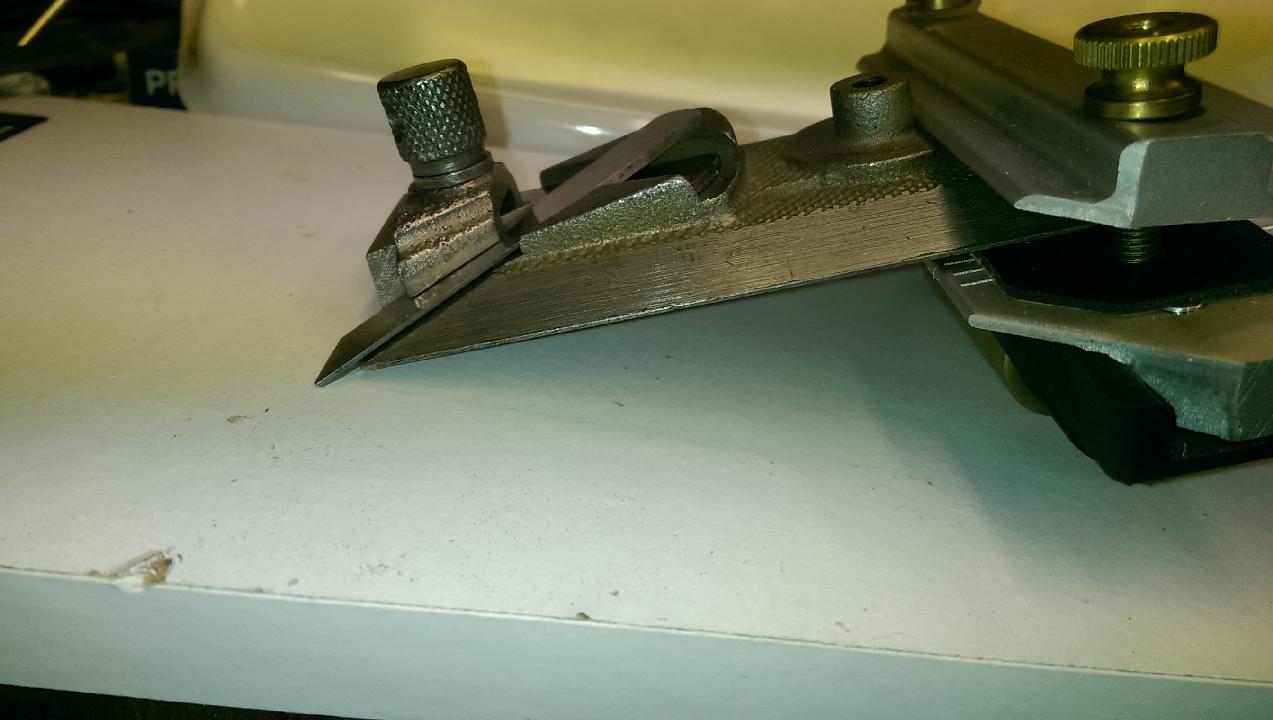

Better still, it looks like it's been USED, not left to rust in its box or whatever, and everything's there with it. There's a small, insignificant chip out of the nose casting on one corner, and the handle looks horrible (you can't see clearly, but I think it was DIPPED in shellac -- the coating is at least 1mm thick and chipping off). It's also got rust coming where the plating has been rubbed off, but that's easy to clean up. Blades have plenty of useful length, although the left-hand one as a couple of small nicks in it. And I was too impatient to let the Plus Gas do its job and chewed the bolt holding the nose on (slightly)

£31, plus very reasonable postage, so I'm pleased.

I do have one puzzlement though: grinding/honing angles. Ignoring what it's for, it's really a low-angle bevel-up jobbie with a fixed mouth. I'm guessing the casting angle is about 10-15 degrees, certainly not more, so what angles should I grind/hone to for general use, as a starting point? It strikes me that, if an Eclipse is wide enough to fit, I can simply reverse the blades and use the plane body as a carrier, to get a clean bevel. The previous owner flattened the backs for me!

So, team: primary and secondary bevel angles?

E.

PS: it's not rust below the handle in the pic, it's flakes of shellac, I think.

Better still, it looks like it's been USED, not left to rust in its box or whatever, and everything's there with it. There's a small, insignificant chip out of the nose casting on one corner, and the handle looks horrible (you can't see clearly, but I think it was DIPPED in shellac -- the coating is at least 1mm thick and chipping off). It's also got rust coming where the plating has been rubbed off, but that's easy to clean up. Blades have plenty of useful length, although the left-hand one as a couple of small nicks in it. And I was too impatient to let the Plus Gas do its job and chewed the bolt holding the nose on (slightly)

£31, plus very reasonable postage, so I'm pleased.

I do have one puzzlement though: grinding/honing angles. Ignoring what it's for, it's really a low-angle bevel-up jobbie with a fixed mouth. I'm guessing the casting angle is about 10-15 degrees, certainly not more, so what angles should I grind/hone to for general use, as a starting point? It strikes me that, if an Eclipse is wide enough to fit, I can simply reverse the blades and use the plane body as a carrier, to get a clean bevel. The previous owner flattened the backs for me!

So, team: primary and secondary bevel angles?

E.

PS: it's not rust below the handle in the pic, it's flakes of shellac, I think.