Hi y'all,

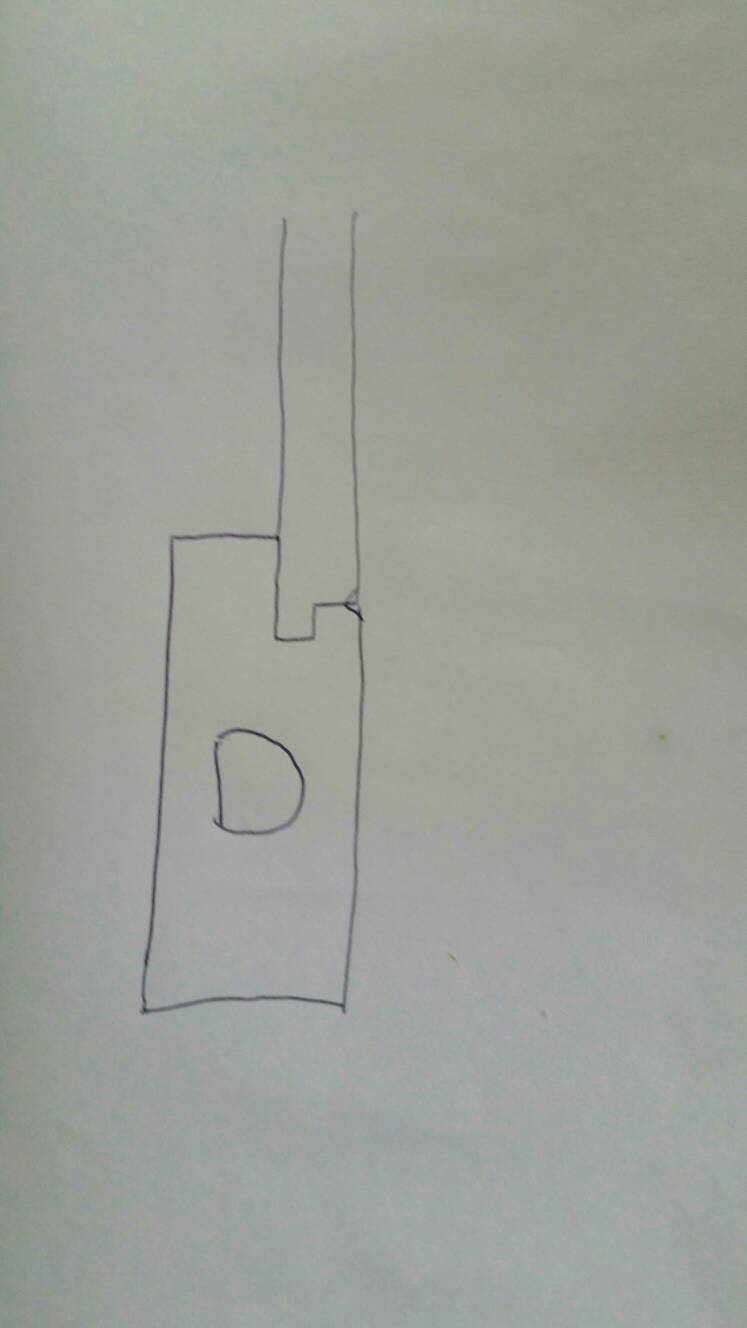

I'm having another go at making an external door, but I'm still unsure of the correct rebate position. I would like to make this door:

In doing so, the tongue and groove panelling must meet flush with the rails. This is to ensure water can't pool on the horizontal surface of the rail and eventually rot the timber. SO....

A - offers most strength, the 18mm panel is fully rebated into the stiles. However, the panels are not flush with the stiles. So, this is not an option.

B - A 10mm x 10mm rebate, offset 8mm from the front of the door. This brings the effective thickness of the panels down to 10mm. Is this considered strong enough? Also, I can't find a 10mm rebate cutter, leading to...

C - A 10mm x 12.7mm rebate, offset 5.3mm from the front of the door. Thicker panels, but 5.3mm seems a bit thin to me. I'm wondering if this will curl/distort over time as it's thin. (12.7mm is the with of most rebate cutters I can find.)

Finally, is there a decent book out there that would explain issues such as this? I have John Birchard's books, but they don't address these aspects.

Thanks

I'm having another go at making an external door, but I'm still unsure of the correct rebate position. I would like to make this door:

In doing so, the tongue and groove panelling must meet flush with the rails. This is to ensure water can't pool on the horizontal surface of the rail and eventually rot the timber. SO....

A - offers most strength, the 18mm panel is fully rebated into the stiles. However, the panels are not flush with the stiles. So, this is not an option.

B - A 10mm x 10mm rebate, offset 8mm from the front of the door. This brings the effective thickness of the panels down to 10mm. Is this considered strong enough? Also, I can't find a 10mm rebate cutter, leading to...

C - A 10mm x 12.7mm rebate, offset 5.3mm from the front of the door. Thicker panels, but 5.3mm seems a bit thin to me. I'm wondering if this will curl/distort over time as it's thin. (12.7mm is the with of most rebate cutters I can find.)

Finally, is there a decent book out there that would explain issues such as this? I have John Birchard's books, but they don't address these aspects.

Thanks