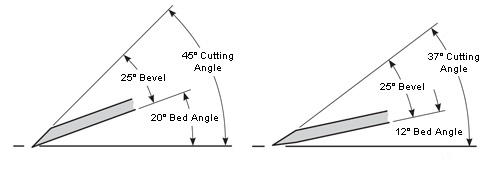

David, your references are for BD planes. I would not disagree with 30+ degrees for A2 when in a Bailey or other BD plane. But the topic here is a block plane. This has a 12 degree bed and holds the blade bevel up.

For a 12 degree bed BU plane the situation is very different from a 45 degree BD bed. The lower vector is a game changer. Don’t forget the comparison I made of BU vs BD shooting planes. This was a controlled study.

Link:

http://www.inthewoodshop.com/ToolReview ... Plane.html

The results were clearcut: 25 degree A2 blade BU on a 12 degree bed (Veritas Shooting Plane) held its edge twice as long as a 30 degree A2 blade BD on a 45 degree bed (Lie Nielson #51 shooting plane). Both planed the same wood and were used on a Stanley #52 shooting board.

Regards from Perth

Derek

Edit to add: I have used a Veritas LA jack on a shooting plane and to smooth end grain for over a decade. For most of these years the blade was A2 and it was always ground and honed at 25 degrees. In this time, the low bevel angle remained consistent and reliable .. and chip free.

Note that I am not a fan of A2, but give credit where it is due.