Jacob

What goes around comes around.

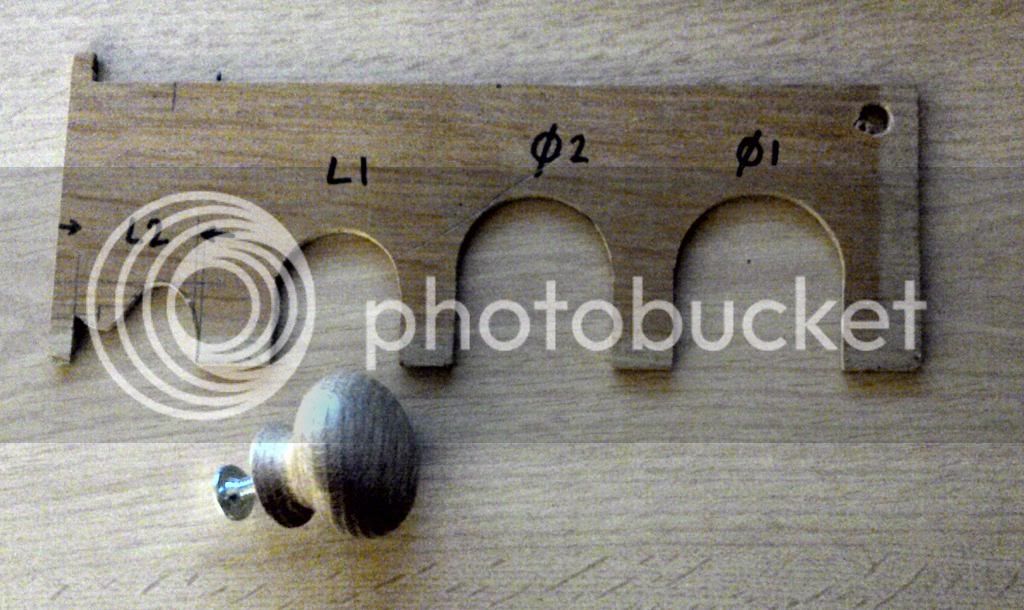

Is there a quick easy way of cutting spigots accurately on furniture knobs and shaker pegs etc? I can do it by sizing with callipers and then adjusting but it seems to take several goes. There must be a gadget. 1/2" or 5/8"

I do a longish blank - rough out several knobs/pegs and spigots well over size - finish one and cut it off - repeat. Is there a better way to turn them if you have a lot to do?

I do a longish blank - rough out several knobs/pegs and spigots well over size - finish one and cut it off - repeat. Is there a better way to turn them if you have a lot to do?