jeffinfrance

Established Member

- Joined

- 3 Jul 2009

- Messages

- 330

- Reaction score

- 0

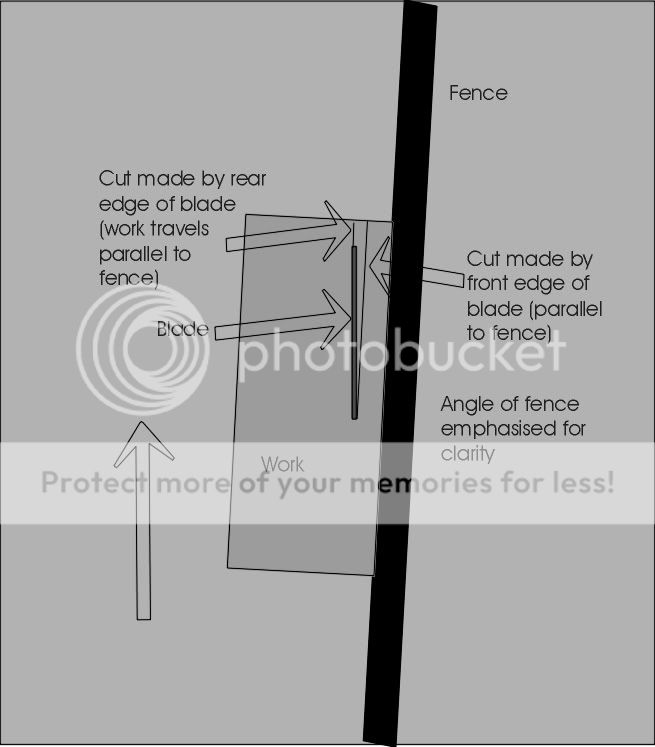

should a parallel fence (table saw) actually be ...parallel?

according to my fence supplier it shouldn't. apparently it should splay away from the blade at the far end once past the saw blade to prevent burning.

my rudimentary understanding of maths and physics tells me this would offer up the piece at an angle to the saw blade (when using the fence as it should when ripping, ie not extending past the blade). when using the fence incorrectly, ie long past the blade, i can see the point as the riving knife will take over to guide the piece and not snag on the splayed fence.

what do you guys think?

jeff

according to my fence supplier it shouldn't. apparently it should splay away from the blade at the far end once past the saw blade to prevent burning.

my rudimentary understanding of maths and physics tells me this would offer up the piece at an angle to the saw blade (when using the fence as it should when ripping, ie not extending past the blade). when using the fence incorrectly, ie long past the blade, i can see the point as the riving knife will take over to guide the piece and not snag on the splayed fence.

what do you guys think?

jeff