I've seen mixed reviews of the Trend airflow pro. The JSP powercap seems to be lighter and more user friendly. The big difference is that the trend is rated AFP20, suitable for fine mdf dust whereas the powercap is only rated to AFP10 and not suitable for fine dusts such as mdf. Is this correct?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Powered Respirators

- Thread starter Rewound

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

StilwellDesigns

Established Member

In the market for a respirator - good info so far keep it coming!

Thanks for that.Sundstrom's SR500 has a two speed fan that delivers 175 or 245 litres per minute.

The 3m versaflo tr300 and tr600 are specified at 2 or 3 speeds 185 / 205 / 225 lpm depending on the model.

Both have a feedback system that increases power to the fan and maintains flow as the filter becomes loaded. And an audible alarm when it can no longer maintain that airflow.

I don't know how the devices measure airflow, but to test performance, the sundstrom has a nylon bag with a simple "ball in a slightly larger tube" pressure gauge. The fan is connected to the bag, air blows in and leaks through the fabric of the bag, and the pressure read from the gauge.

It might be worth downloading the manuals for these three, but i'll look and if the fan is visible without dismantling, I'll put up a photo.

This is taken looking into the air outlet of the Sundstrom SR500.

If you are familar with impeller types, it's recognisable as a single stage centrifugal impeller, about 5" diameter.

These draw air into the centre and "throw" it outwards, the same way that a workshop hvlp dust extractor works but the impeller is more refined and of different proportions (bigger diameter, slimmer, closed on both sides and backward curving blades) which greatly increase the pressure that it develops.

Similar style of impellers are used in power showers, some air curtains, air blade cutters, and many industrial processes.

View attachment 153056

From what I have been playing with this last few days, it has to be the centrifugal type fan, and luckily I have found a nice 12v one that I think could be powerful enough - won't know until its sucking through some p3 filters, but without filters the flow seems excessive.

Luckily as well, someone is going to loan me a 'powercap' so that should give me some idea of flow rates et cetera

------------------

Does anyone know what the difference is between HEPA & P3 ?

seems to me they are pretty much the same, apart from the hepa filters for vacuum cleaners are bigger cheaper and in some cases, washable. May be they would be better for my home made belt mounted respirator ?

HEPA is an acronym. High Efficiency Particulate Air or something. Maybe open for interpretation.

P3 is a euro standard with a full set of specifications that performance can be measured against ?

Just a thought, but as filters are a consumable, you could actually use genuine Sundstrom filters and prefilters on your DIY build. One type is screw on with a big thread. Grease up a thread so it will release and you could probably mould a pair of matching sockets for them to screw into out of epoxy putty or similar. Another type is just a stubby cylinder so you could invent a different holder.

The prefilters do a lot of the work so the P3 units last pretty well.

P3 is a euro standard with a full set of specifications that performance can be measured against ?

Just a thought, but as filters are a consumable, you could actually use genuine Sundstrom filters and prefilters on your DIY build. One type is screw on with a big thread. Grease up a thread so it will release and you could probably mould a pair of matching sockets for them to screw into out of epoxy putty or similar. Another type is just a stubby cylinder so you could invent a different holder.

The prefilters do a lot of the work so the P3 units last pretty well.

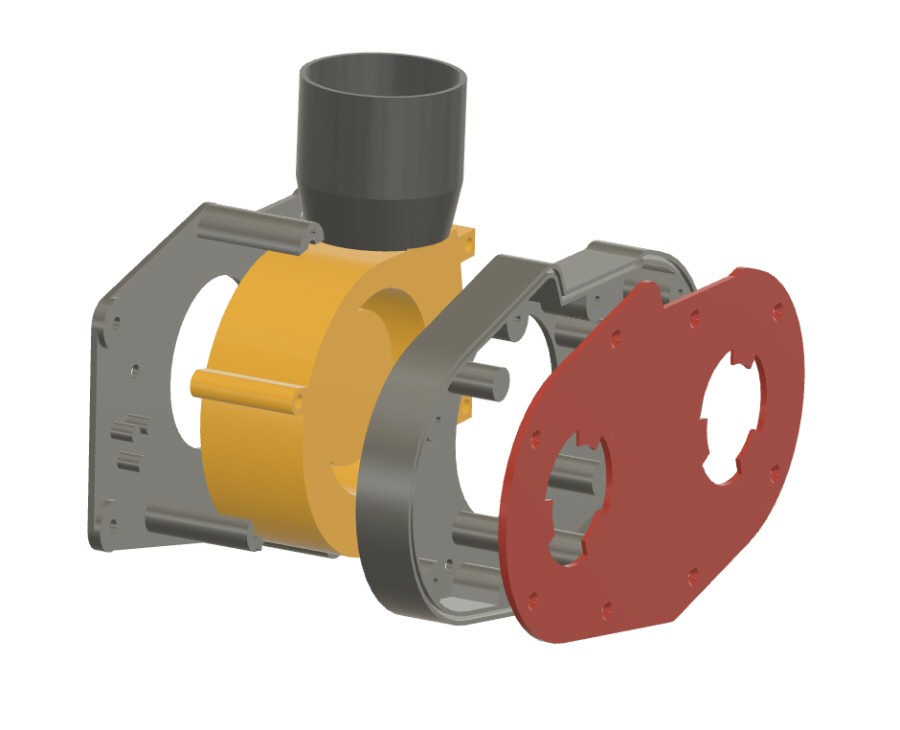

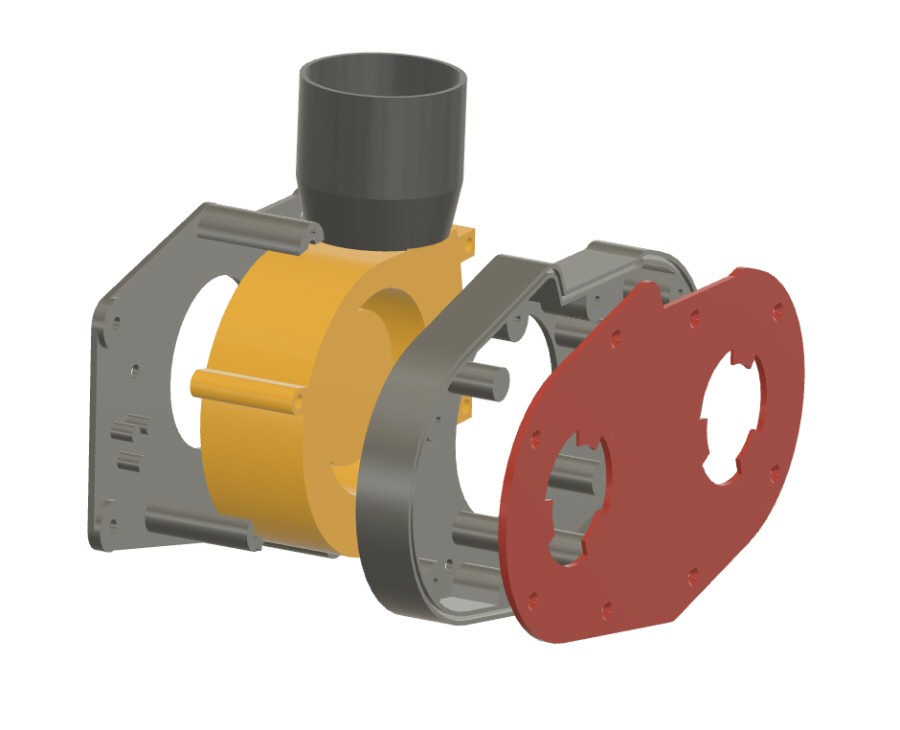

This is the Versaflo TR300 belt unit.

Opened up we can see it also user a skinny centrifugal fan in a plastic housing that shows the outlines of a snail shell type enclosure. The air is pulled in at the centre and exits vertically straight into the place where the hose connects.

That silver boss is part of the motor and spins with the fan.

Opened up we can see it also user a skinny centrifugal fan in a plastic housing that shows the outlines of a snail shell type enclosure. The air is pulled in at the centre and exits vertically straight into the place where the hose connects.

That silver boss is part of the motor and spins with the fan.

But HEPA has its own european standards, and as far as I can tell they are pretty much the same as P3, It is just a thought for more sensibly priced filters in the future. Out of interest, what is the dimensions of that large filter in your Versiflo, it may give me an idea of the surface area needed.HEPA is an acronym. High Efficiency Particulate Air or something. Maybe open for interpretation.

P3 is a euro standard with a full set of specifications that performance can be measured against ?

Just a thought, but as filters are a consumable, you could actually use genuine Sundstrom filters and prefilters on your DIY build. One type is screw on with a big thread. Grease up a thread so it will release and you could probably mould a pair of matching sockets for them to screw into out of epoxy putty or similar. Another type is just a stubby cylinder so you could invent a different holder.

The prefilters do a lot of the work so the P3 units last pretty well.

And yes you are correct that there is nothing stopping me using existing respiratory filters. in my initial build I'm going to use the GVS P3 filters, simply because I all ready have them, about 4 pair I think this is the excellent mask I have used for a good few years now.

However alredy run into a littlle problem, I thought simply creating the correct size cut out these filters would just ease in, not so simple though. Its the soft masks that flex when fitting these, and I'm worrying that manipulating them into a hard plastic could damage the paper filter - which would sort of defeat the object of the exercise

But I have moved forward with the build, the fan that I have will be man enough for the job by a good margin, probably be able to run it slower and use less power.

The hose connector was very poor, and useless for the pipe that I have, so managed to make some alterations and print out something very robust, this connection will be strong enough to use as the handle, no clips ties or adhesives needed

notice the inside coil that perfectly fits the flexible pipe!

Hiya ! The fan looks really promising. If you nail this, you'll be able to sell plans

The 3M filter is about 17x9 cm. Pleated like your GVS ones but 1.5x to 2x as thick, which must increase the surface area.

The whole of the dust facing side is open to incoming air. The back of the filter is closed except for a circular outlet with a silicon washer around it. That's about 5cm diameter and couples the filter to the inlet of the fan in the last photo of my previous post.

The 3M filter is about 17x9 cm. Pleated like your GVS ones but 1.5x to 2x as thick, which must increase the surface area.

The whole of the dust facing side is open to incoming air. The back of the filter is closed except for a circular outlet with a silicon washer around it. That's about 5cm diameter and couples the filter to the inlet of the fan in the last photo of my previous post.

Inspector

Nyuck, Nyuck, Nyuck!

Miele vacuum cleaners can have a HEPA final stage filter (after the bag) put into them. Hey are roughly 90 x 180. A piece of the bag cut to fit would make a decent pre filter. One downside is the are not cheap. Don’t know how they compare cost-wise to other filters. An option to ponder.

Pete

Pete

wallace

Established Member

Early on I messed about with making my own mask, but instead of having a unit that filtered on my person. I had a pump that took fresh air from a clean source and fed a mask via a flexible pipe.

I bizarrely used a miliatary fan that came off a cold war radar unit. It worked really well. Only problems were the noise of the fan resonated down the pipe and the length of pipe restricted where you could walk with the mask on.

I bizarrely used a miliatary fan that came off a cold war radar unit. It worked really well. Only problems were the noise of the fan resonated down the pipe and the length of pipe restricted where you could walk with the mask on.

Problem is with the filters is; are they what they say they are, and as far as I know there is no real way of telling. Take these for instanceMiele vacuum cleaners can have a HEPA final stage filter (after the bag) put into them. Hey are roughly 90 x 180. A piece of the bag cut to fit would make a decent pre filter. One downside is the are not cheap. Don’t know how they compare cost-wise to other filters. An option to ponder.

Pete

4-pcs HEPA Filter for SHARK WV200 WV200UK WV251 Cordless Handheld Vacuum Cleaner | eBay

£2.25 each, they could be as good, even made in the same factory as the high price top-marque makes - but they might not be, which would rather defeat the whole object.

Yes, I do like the look of those, and maybe if my build is succesful that may be mark2. But I have a long way to go yet.Hiya ! The fan looks really promising. If you nail this, you'll be able to sell plans

The 3M filter is about 17x9 cm. Pleated like your GVS ones but 1.5x to 2x as thick, which must increase the surface area.

The whole of the dust facing side is open to incoming air. The back of the filter is closed except for a circular outlet with a silicon washer around it. That's about 5cm diameter and couples the filter to the inlet of the fan in the last photo of my previous post.

Filter size has to be very important on a powered respirator. We breath at 6-8 litres per minute, these powered respirators are pumping the best part of 200 litres per minutes, that is 20 to 25 times as mch air to clean.

The GVS that I was going to use has a surface area of 27.05 sq cm and a thickness of 0.9cm giving a volume of 47cc for a pair.

The Powercap filters would have a volume of 155cc,

and your 3M (if the same thickness of the powercap(19mm) would be a whopping 290cc.

(off course it may be a bit more comples that working out the volume of these filter bodies, the GVS has closer pleats so may be better than I am wildly guessing at)

So on that note I have now decided to change my initial design and use the P2 filters that have come with the powercap that I have very kindly been given a loan of. More on the powercap later, however I am not greatly impressed considering the high price.

So back to the drawing board, pity, I was just ready to print of my GVS plan.

@Sideways the flexible pipe that runs from your belt to the helmet, what size is it ? length, internal dia etc,

As to the build - a bit further forward, have completed the belt unit (apart from the battery) and it works well. I have tried to do some air flow comparisons with the powercap, difficlt to know how to do this accurately, but chose to stick wind meter completely over out let and force all air through (see image below) (I doubt this is a good way of measuring volume but I get a number)

powecap give a reading of 6.2

My home build I have been experimenting with various voltages

9v = 5.5

10v =6.1

11v = 6.9

12v = 7.7

11v is running at 0.41 amps so a 2000mah battery would give up to 5 hourds run time.

As to the build - a bit further forward, have completed the belt unit (apart from the battery) and it works well. I have tried to do some air flow comparisons with the powercap, difficlt to know how to do this accurately, but chose to stick wind meter completely over out let and force all air through (see image below) (I doubt this is a good way of measuring volume but I get a number)

powecap give a reading of 6.2

My home build I have been experimenting with various voltages

9v = 5.5

10v =6.1

11v = 6.9

12v = 7.7

11v is running at 0.41 amps so a 2000mah battery would give up to 5 hourds run time.

I'll measure up the 3m, Sundstrom and Optrel tomorrow. They vary a little. Sundstrom is my #1 but as I like Optrel welding gear, I adapted the 3M blower and hose from the very first air fed set I bought onto the rather smaller diameter inlet on an optrel grinding mask.

For measuring flow, look at this. Maybe one will float through ebay at some point.

https://www.arco.co.uk/Web-Taxonomy...ed-Air-Supply-Flow-Meter/p/PIMM00000000023556

It's a simple bag with "calibrated" leakage and an equally simple floating bead type low pressure gauge.

For measuring flow, look at this. Maybe one will float through ebay at some point.

https://www.arco.co.uk/Web-Taxonomy...ed-Air-Supply-Flow-Meter/p/PIMM00000000023556

It's a simple bag with "calibrated" leakage and an equally simple floating bead type low pressure gauge.

Last edited:

3M hose.

ID of the end fitting (which is a couple of mm less than the inside of the hose), is 26mm dia

Here's the optrel face shield with my DIY aluminium adapter so the 3M hose will fit.

The ID of the connector on the Optrel visor is 25mm

ID of the end fitting (which is a couple of mm less than the inside of the hose), is 26mm dia

Here's the optrel face shield with my DIY aluminium adapter so the 3M hose will fit.

The ID of the connector on the Optrel visor is 25mm

@Sideways How do your respirators go together? Do you don it as all one piece, or do you for instance put the belt and helmet on separatly then connect them with the hose.

thanks for your input on the hose size, it is a little smaller than the one I am goint to use (ID 37mm) I'm wondering if I would be better with a smaller lighter weight hose, more restrictive on the air flow but less cumbersome.

Do you ever use any pre pre filters. ie. something before the prefilter to catch a lot of the muck? I have been using some sponge type stuff before the prefilter on the powercap, it gets very dirty and does not appear to restrict flow.

thanks for your input on the hose size, it is a little smaller than the one I am goint to use (ID 37mm) I'm wondering if I would be better with a smaller lighter weight hose, more restrictive on the air flow but less cumbersome.

Do you ever use any pre pre filters. ie. something before the prefilter to catch a lot of the muck? I have been using some sponge type stuff before the prefilter on the powercap, it gets very dirty and does not appear to restrict flow.

@Rewound ,

I imagine different people use the respirators in different ways.

I find reaching behind my back to connect the hose quite awkward so I leave the hose attached to the headgear except for when its packed away.

Usually, I put the waist pack on first, with or without the hose attached, then headset second.

If not connected first, I reach back, feel for hose end and fan outlet and make that connection as it's the easiest to do blind on both the 3m and sundstrom. Both have a bayonet with just a quarter turn. It the connection were threaded, screw it all together first, put on the belt next and the headset last.

You learn where the power switch is and press to start, press to change speed, long press to stop.

You don't see the display in use, behind you, but the good respirators have audible alarms when the fan starts to struggle and you hear the fan anyway.

Both my sets take prefilters. They are essential because they catch a lot of the coarse dirt. Sundstrom especially which I use for spraying has easy change prefilters and a good number included in each box of p3 filters. It's easy to see them turn green, blue, yellow after a job and they really protect the p3 which thankfully then last a long time. When you use a fume filter, the order you stack them is prefilter first, p3 next and carbon filter last, going outside to inside.

For welding, use a fine stainless mesh prefilter so sparks don't set your filters alight it's very cheap on amazon and cuts with workshop scissors.

it's very cheap on amazon and cuts with workshop scissors.

Oh, the hoses are really flexible.

They are consumable. You could buy an original top brand one, esp if one came up surplus, and adapt it to your unit. Just be careful about length. Headset designs vary so sundstrom and 3m versaflo hoses are short while optrel ones need to be long.

I imagine different people use the respirators in different ways.

I find reaching behind my back to connect the hose quite awkward so I leave the hose attached to the headgear except for when its packed away.

Usually, I put the waist pack on first, with or without the hose attached, then headset second.

If not connected first, I reach back, feel for hose end and fan outlet and make that connection as it's the easiest to do blind on both the 3m and sundstrom. Both have a bayonet with just a quarter turn. It the connection were threaded, screw it all together first, put on the belt next and the headset last.

You learn where the power switch is and press to start, press to change speed, long press to stop.

You don't see the display in use, behind you, but the good respirators have audible alarms when the fan starts to struggle and you hear the fan anyway.

Both my sets take prefilters. They are essential because they catch a lot of the coarse dirt. Sundstrom especially which I use for spraying has easy change prefilters and a good number included in each box of p3 filters. It's easy to see them turn green, blue, yellow after a job and they really protect the p3 which thankfully then last a long time. When you use a fume filter, the order you stack them is prefilter first, p3 next and carbon filter last, going outside to inside.

For welding, use a fine stainless mesh prefilter so sparks don't set your filters alight

Oh, the hoses are really flexible.

They are consumable. You could buy an original top brand one, esp if one came up surplus, and adapt it to your unit. Just be careful about length. Headset designs vary so sundstrom and 3m versaflo hoses are short while optrel ones need to be long.

Last edited:

Oh, the hoses are really flexible.

They are consumable. You could buy an original top brand one, esp if one came up surplus, and adapt it to your unit. Just be careful about length. Headset designs vary so sundstrom and 3m versaflo hoses are short while optrel ones need to be long.

I'm really curious as to just how flexible and light the top brand ones are, very difficult to make any comparisons but how would you compare them to , for instance, the flxible hose that comes with the likes of a Henty?

the one I'm intending to use weighs in at 230g per meter - its a bit of an ask you to weigh yours so no probs if you don't.

The visor I am intending using arrives this week (honywell look-a-like from china for £12) so I can carry on with the build. I'm very pleased so far with the fan and filter housing.

The hoses are not so much light as incredibly flexible. They have a very tight minimum bend radius for their diameter.

A completely different animal compared to even the most flexible extraction hose which is the new braided festool one.

I'll get them on the scales in the next day or two

A completely different animal compared to even the most flexible extraction hose which is the new braided festool one.

I'll get them on the scales in the next day or two

This is a really interesting thread - I am sure it should be possible to design and make a system to deliver filtered air to a face mask for a lot less than the professional kit (as Rewound is demonstrating). If air could be drawn from outside the workshop it might be even easier - when I am turning I don't need to move far so wouldn't need a very long hose!

As promised. This is a 3M Versaflo BT30 hose.

Long enough for use with a headset that has a port facing downward at the back of the head. Not long enough for an Optrel style hose connection on the crown of the head.

201 grams and 850mm max length

Long enough for use with a headset that has a port facing downward at the back of the head. Not long enough for an Optrel style hose connection on the crown of the head.

201 grams and 850mm max length

Similar threads

- Replies

- 1

- Views

- 423