Hi Guys,

As many of you know I'm a carver and woodturner and my dust problems are getting worse and worse and I would like some advice on how to deal with it.

Currently I am using a woodturning lathe, foredom (power carver) and bench drill and bandsaw to make my wares but the dust is getting everywhere. I was using a vacuum with a homemade cyclone to try and get rid of the dust but I'm finding its really not helping.

I need something more substantial and am trying to solve this problem while at the same time using as little space as possible. My space is at a premium. I have a 7 x 7 shed to house all my machines, wood and tools in and am hoping to find a small dust extractor that will fit in with my workspace.

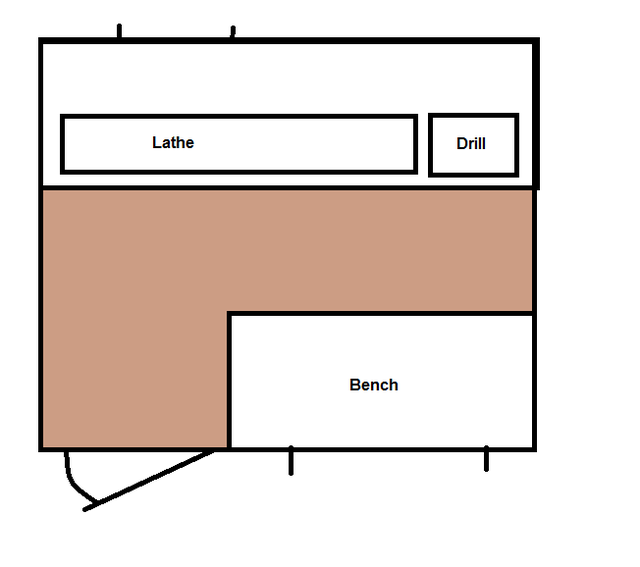

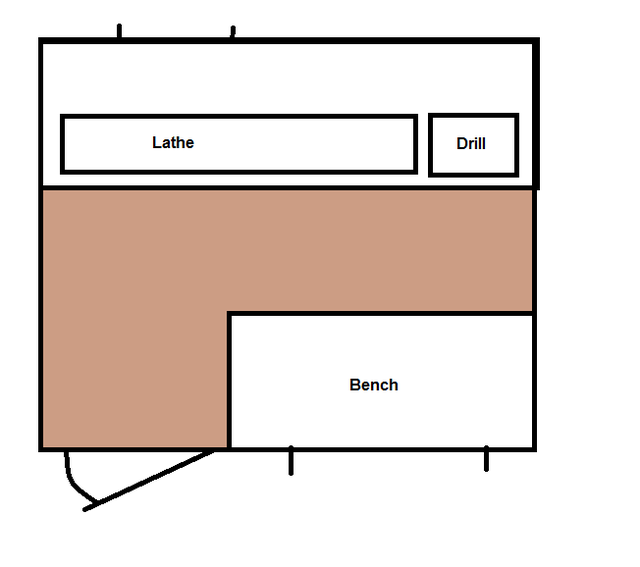

I've attached a few photos of my shed and a floor plan to give you a rough idea.

A floor plan as well

The cabinet currently in the left under my lathe is where my vacuum currently is and I'm allowing this space for my new extractor. I have my eye on this one here

http://www.axminster.co.uk/axminster-ho ... tor-501262

But I don't know if this will be enough for my needs and also it only has one port and I have a number of machine in a small space. How could I have many machines connected to it via one port? Also I have problems with the size of the hose, 100mm is quite large for such a small workspace and I was wondering if I could make the hose thinner by reducing it without affecting the suction. I reckon I will have to put the hose up in my ceiling but have no idea how to fix it in place or the best way to route it either. I'm not trying to remove all dust but just the bulk of it really. I still wear a face mask as well but this doesn't stop me and my shed getting covered in the stuff whatever I'm doing.

If anyone has any suggestions to a different extractor or in fact any ideas then I would greatly appreciate them.

Thank you

As many of you know I'm a carver and woodturner and my dust problems are getting worse and worse and I would like some advice on how to deal with it.

Currently I am using a woodturning lathe, foredom (power carver) and bench drill and bandsaw to make my wares but the dust is getting everywhere. I was using a vacuum with a homemade cyclone to try and get rid of the dust but I'm finding its really not helping.

I need something more substantial and am trying to solve this problem while at the same time using as little space as possible. My space is at a premium. I have a 7 x 7 shed to house all my machines, wood and tools in and am hoping to find a small dust extractor that will fit in with my workspace.

I've attached a few photos of my shed and a floor plan to give you a rough idea.

A floor plan as well

The cabinet currently in the left under my lathe is where my vacuum currently is and I'm allowing this space for my new extractor. I have my eye on this one here

http://www.axminster.co.uk/axminster-ho ... tor-501262

But I don't know if this will be enough for my needs and also it only has one port and I have a number of machine in a small space. How could I have many machines connected to it via one port? Also I have problems with the size of the hose, 100mm is quite large for such a small workspace and I was wondering if I could make the hose thinner by reducing it without affecting the suction. I reckon I will have to put the hose up in my ceiling but have no idea how to fix it in place or the best way to route it either. I'm not trying to remove all dust but just the bulk of it really. I still wear a face mask as well but this doesn't stop me and my shed getting covered in the stuff whatever I'm doing.

If anyone has any suggestions to a different extractor or in fact any ideas then I would greatly appreciate them.

Thank you