Ed Bray

Established Member

I received the Woodriver 5½ from the pass around earlier this week. I had a little play with it on a bit of cut off pine in the front room (don't tell my wife) when I received it, basically I ran the pine across the sole of the plane whilst holding it upside down. But, whilst the shavings from the included IBC blade were excellent, I was not too impressed with the shavings from the standard blade but this could have been because it needed sharpening. I was impressed with the casting and in particular the larger adjustment knob.

Let me first explain, I am no tradesman, all my woodworking knowledge has been gleaned from books, the internet (you tube and forums like this) and trial and error, and whilst I have built many items they have mainly been made with the use of power tools. Until earlier this year my experience with hand tools was very limited. Since then though I have bought a considerable number of hand tools and been learning how to fettle and use them. Just be aware that this shoot out is not by any means scientific but I have tried to make it as 'real world' as possible and the results have given me an experience with different planes and a better understanding of what I should expect from my planes.

I chose 4 of my own planes to pit against the Woodriver 5½, these were a Stanley 4½, a Stanley 5½, a Veritas 4½ and my Quangsheng 62. I also chose 5 types of wood, these were an Oak floorboard (front edge), a bit of reclaimed Iroko (2nd from front), a piece of Pine, (3rd from front), an unknown wood (4th from front) and a bit of Cedar of Lebanon (nearest the planes). These can all be seen in the photo below:

The Stanley planes were sourced from either this forum or ebay and I replaced the blades with 3mm replacement blades and whilst the Stanley 4½ had a new thicker blade and a new thicker chipbreaker the Stanley 5½ uses the original chipbreaker with the New thicker Blade, The Quangsheng and Veritas use the blades and chipbreaker that were supplied with them.

With the exception of both the IBC Blade (states that it can be used straight out of the packaging) and the Quangsheng blade I sharpened all the other blades exactly the same way with a few strokes at 29° with a 1000 grit diamond stone until I felt a burr, then a few strokes at 1200 grit before removing the burr on the back using the ruler trick. Every blade was treated exactly the same way and they were all extremely sharp, the 2 plasters now on my fingers will attest to that.

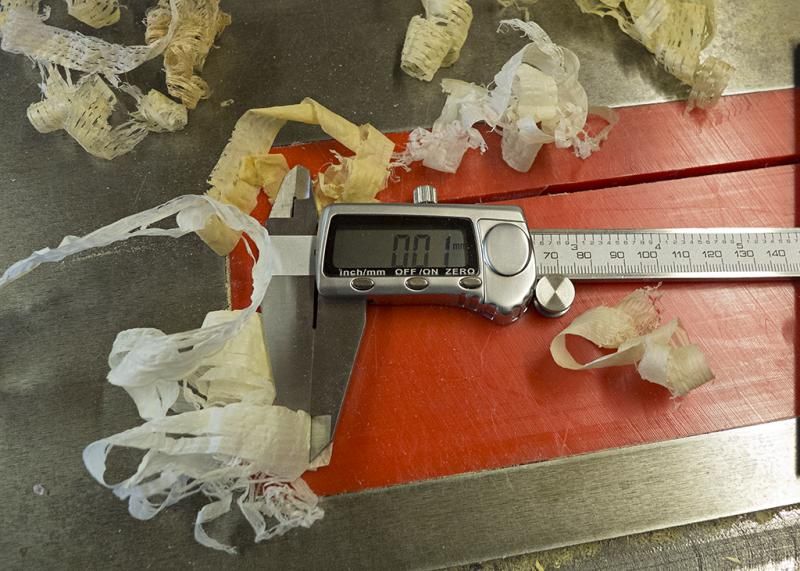

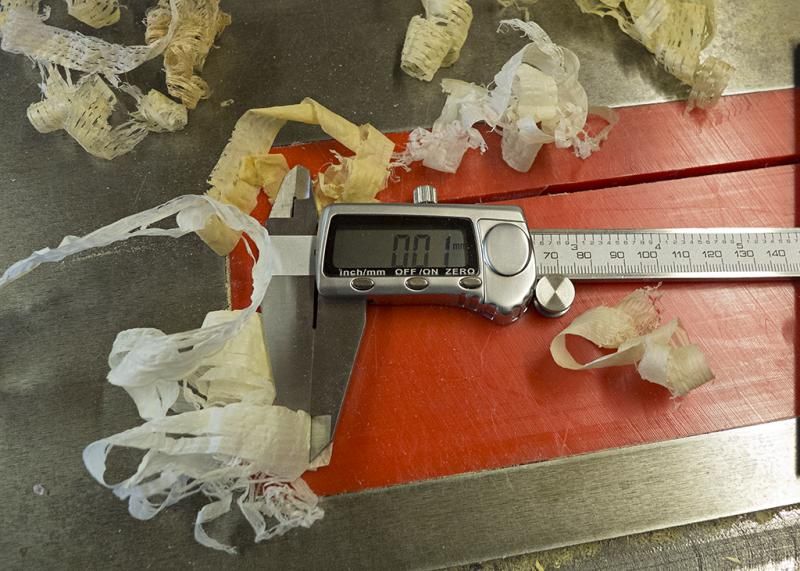

I mounted each piece of wood in the workmate and then adjusted each plane until I got a shaving, I then backed off the iron as much as possible to see how thin a shaving I could get. These were then measured with my digital calipers and the readings recorded. This really opened my eyes as I was unaware how well my old Stanley Planes would actually perform in competition with the newer, more expensive and luxurious planes I was including. The results are as follows below:

Oak:

Stanley 4½ ThickerBlade/Chipbreaker 0.01mm

Veritas 4½ Standard Blade/Chipbreaker 0.01mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.01mm

Woodriver 5½ Standard Blade/Chipbreaker 0.04mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.01mm

Quangsheng 62 Standard Blade 0.01mm

Iroko:

Stanley 4½ ThickerBlade/Chipbreaker 0.02mm

Veritas 4½ Standard Blade/Chipbreaker 0.03mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.05mm

Woodriver 5½ Standard Blade/Chipbreaker 0.03mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.02mm

Quangsheng 62 Standard Blade 0.02mm

Pine:

Stanley 4½ ThickerBlade/Chipbreaker 0.05mm

Veritas 4½ Standard Blade/Chipbreaker 0.03mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.05mm

Woodriver 5½ Standard Blade/Chipbreaker 0.05mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.02mm

Quangsheng 62 Standard Blade 0.01mm

Unknown Wood:

Stanley 4½ ThickerBlade/Chipbreaker 0.03mm

Veritas 4½ Standard Blade/Chipbreaker 0.02mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.03mm

Woodriver 5½ Standard Blade/Chipbreaker 0.04mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.01mm

Quangsheng 62 Standard Blade 0.01mm

Cedar of Lebanon:

Stanley 4½ ThickerBlade/Chipbreaker 0.02mm

Veritas 4½ Standard Blade/Chipbreaker 0.01mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.04mm

Woodriver 5½ Standard Blade/Chipbreaker 0.04mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.01mm

Quangsheng 62 Standard Blade 0.02mm

The planed edge of the Oak is facing the camera, all the other planed surfaces are at the top as you look at them.

Assorted shavings from the various woods.

So, what have I learned?

1) I did not waste my time fettling the 2 older Stanley Planes (I have 3 others to do yet and they will now all get similar treatment) and the results obtained are more about how the blades are sharpened than what plane they are used in.

2) The difference between results from the planes are negligible in the real world, the best was 0.01mm which is 1/100th of a mm whilst the worst result was 1/20th of a mm, this would still be fine enough for me (and I suspect many others).

3) The thicker replacement blades I bought (14E each from Finetools.com) take a nice edge and work well in the planes (even though I was told on this forum they wouldn't fit).

4) The Quangsheng 62 performed the best of all with its Standard 25° Blade although the Woodriver did match it when fitted with the IBC blade/chipbreaker (but that costs an additional £90). I have never yet had occasion to use the 2 other blades (38° & 50°) that came with it.

All the wood had the most marvellous finish from every plane, even those that took a humungous 0.05mm thick shaving and whilst it cannot be seen in the photographs the planed wood felt as smooth as silk.

So. my conclusions are that if you already have a plane of a specific size then you may well be better of fettling it and perhaps replacing the blade and chipbreaker. If not, you could do a lot worse than purchasing a Woodriver or Quangsheng Plane as it will be pretty good right out of the box and it's performance will probably only be limited by your sharpening and use of the plane than any shortcomings associated with it.

Really appreciate the loan of the plane and I have now changed my Christmas preference and will likely ask for a #7 Woodriver or Quangsheng now rather than the #6.

Let me first explain, I am no tradesman, all my woodworking knowledge has been gleaned from books, the internet (you tube and forums like this) and trial and error, and whilst I have built many items they have mainly been made with the use of power tools. Until earlier this year my experience with hand tools was very limited. Since then though I have bought a considerable number of hand tools and been learning how to fettle and use them. Just be aware that this shoot out is not by any means scientific but I have tried to make it as 'real world' as possible and the results have given me an experience with different planes and a better understanding of what I should expect from my planes.

I chose 4 of my own planes to pit against the Woodriver 5½, these were a Stanley 4½, a Stanley 5½, a Veritas 4½ and my Quangsheng 62. I also chose 5 types of wood, these were an Oak floorboard (front edge), a bit of reclaimed Iroko (2nd from front), a piece of Pine, (3rd from front), an unknown wood (4th from front) and a bit of Cedar of Lebanon (nearest the planes). These can all be seen in the photo below:

The Stanley planes were sourced from either this forum or ebay and I replaced the blades with 3mm replacement blades and whilst the Stanley 4½ had a new thicker blade and a new thicker chipbreaker the Stanley 5½ uses the original chipbreaker with the New thicker Blade, The Quangsheng and Veritas use the blades and chipbreaker that were supplied with them.

With the exception of both the IBC Blade (states that it can be used straight out of the packaging) and the Quangsheng blade I sharpened all the other blades exactly the same way with a few strokes at 29° with a 1000 grit diamond stone until I felt a burr, then a few strokes at 1200 grit before removing the burr on the back using the ruler trick. Every blade was treated exactly the same way and they were all extremely sharp, the 2 plasters now on my fingers will attest to that.

I mounted each piece of wood in the workmate and then adjusted each plane until I got a shaving, I then backed off the iron as much as possible to see how thin a shaving I could get. These were then measured with my digital calipers and the readings recorded. This really opened my eyes as I was unaware how well my old Stanley Planes would actually perform in competition with the newer, more expensive and luxurious planes I was including. The results are as follows below:

Oak:

Stanley 4½ ThickerBlade/Chipbreaker 0.01mm

Veritas 4½ Standard Blade/Chipbreaker 0.01mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.01mm

Woodriver 5½ Standard Blade/Chipbreaker 0.04mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.01mm

Quangsheng 62 Standard Blade 0.01mm

Iroko:

Stanley 4½ ThickerBlade/Chipbreaker 0.02mm

Veritas 4½ Standard Blade/Chipbreaker 0.03mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.05mm

Woodriver 5½ Standard Blade/Chipbreaker 0.03mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.02mm

Quangsheng 62 Standard Blade 0.02mm

Pine:

Stanley 4½ ThickerBlade/Chipbreaker 0.05mm

Veritas 4½ Standard Blade/Chipbreaker 0.03mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.05mm

Woodriver 5½ Standard Blade/Chipbreaker 0.05mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.02mm

Quangsheng 62 Standard Blade 0.01mm

Unknown Wood:

Stanley 4½ ThickerBlade/Chipbreaker 0.03mm

Veritas 4½ Standard Blade/Chipbreaker 0.02mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.03mm

Woodriver 5½ Standard Blade/Chipbreaker 0.04mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.01mm

Quangsheng 62 Standard Blade 0.01mm

Cedar of Lebanon:

Stanley 4½ ThickerBlade/Chipbreaker 0.02mm

Veritas 4½ Standard Blade/Chipbreaker 0.01mm

Stanley 5½ Thicker Blade/Stand Chipbreaker 0.04mm

Woodriver 5½ Standard Blade/Chipbreaker 0.04mm

Woodriver 5½ IBC Blade/ Chipbreaker 0.01mm

Quangsheng 62 Standard Blade 0.02mm

The planed edge of the Oak is facing the camera, all the other planed surfaces are at the top as you look at them.

Assorted shavings from the various woods.

So, what have I learned?

1) I did not waste my time fettling the 2 older Stanley Planes (I have 3 others to do yet and they will now all get similar treatment) and the results obtained are more about how the blades are sharpened than what plane they are used in.

2) The difference between results from the planes are negligible in the real world, the best was 0.01mm which is 1/100th of a mm whilst the worst result was 1/20th of a mm, this would still be fine enough for me (and I suspect many others).

3) The thicker replacement blades I bought (14E each from Finetools.com) take a nice edge and work well in the planes (even though I was told on this forum they wouldn't fit).

4) The Quangsheng 62 performed the best of all with its Standard 25° Blade although the Woodriver did match it when fitted with the IBC blade/chipbreaker (but that costs an additional £90). I have never yet had occasion to use the 2 other blades (38° & 50°) that came with it.

All the wood had the most marvellous finish from every plane, even those that took a humungous 0.05mm thick shaving and whilst it cannot be seen in the photographs the planed wood felt as smooth as silk.

So. my conclusions are that if you already have a plane of a specific size then you may well be better of fettling it and perhaps replacing the blade and chipbreaker. If not, you could do a lot worse than purchasing a Woodriver or Quangsheng Plane as it will be pretty good right out of the box and it's performance will probably only be limited by your sharpening and use of the plane than any shortcomings associated with it.

Really appreciate the loan of the plane and I have now changed my Christmas preference and will likely ask for a #7 Woodriver or Quangsheng now rather than the #6.