OPJ

Established Member

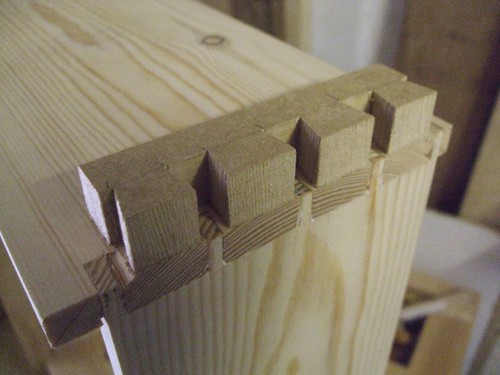

Gluing up a 'complex-looking' carcase like this doesn't need to be difficult; you need to step back, look at it carefully and break it down in to a sequence of smaller, more manageable assemblies. With that in mind, I started by gluing the central runners between the front and back drawer rails.

You could argue that this isn't necessary. The shoulder lengths were spot on 8) and, since both sets of rails are glued in to the relevant stiles, these runners aren't going anywhere! This also meant that, once the glue was dry, I could cramp each assembly flat on my 'bench and plane the joints flush. This way, the drawers should be less likely to bind or catch inside.

This also meant that, once the glue was dry, I could cramp each assembly flat on my 'bench and plane the joints flush. This way, the drawers should be less likely to bind or catch inside.

Speaking of planing and cleaning up, I'm so glad I waited until after the 'bench build to start this job - no more messing about with wobbly trestles for me!!

The back panel will simply be screwed to the rear of the carcase. I almost forgot to cut the rebates before gluing the lot up :wink: - please note, this is probably about as 'dangerous' an operation as I would ever perform in my workshop...

One half assembled, all the joints pulled up nicely. A coat of thinned sanding sealer was applied before assembly, which aids excess glue removal. I'll give it another hour before I attach the other half. This way, I should be able to look at sizing the drawer components in the morning.

This combination with wooden bars and sash cramp heads works quite well although, I do have a couple of problem cramp heads - where you tighten them up (not too tight!) and the b******s start sliding off the job!! :x (That's why I'm using only four from my collection of six.)

You could argue that this isn't necessary. The shoulder lengths were spot on 8) and, since both sets of rails are glued in to the relevant stiles, these runners aren't going anywhere!

Speaking of planing and cleaning up, I'm so glad I waited until after the 'bench build to start this job - no more messing about with wobbly trestles for me!!

The back panel will simply be screwed to the rear of the carcase. I almost forgot to cut the rebates before gluing the lot up :wink: - please note, this is probably about as 'dangerous' an operation as I would ever perform in my workshop...

One half assembled, all the joints pulled up nicely. A coat of thinned sanding sealer was applied before assembly, which aids excess glue removal. I'll give it another hour before I attach the other half. This way, I should be able to look at sizing the drawer components in the morning.

This combination with wooden bars and sash cramp heads works quite well although, I do have a couple of problem cramp heads - where you tighten them up (not too tight!) and the b******s start sliding off the job!! :x (That's why I'm using only four from my collection of six.)