Adam W.

A Major Clanger

It exhibits pallet like qualities.

Get the nails out when the ashes are cold, with a magnet in a plastic beaker. Pull the magnet out and the nails drop off into the ash can whatever.I do do that if I have loads of the stuff, but they do jam the grate riddling. And I use the ashes so still need to extract them from the dust!

Have to say I quite like this : might have a crack at it if I can find 2 similar sized jobs.

Granted, you wouldn't stick a vice on it or anything, but it looks a handy enough piece to roll around the shop!

Have to say I quite like this : might have a crack at it if I can find 2 similar sized jobs.

Granted, you wouldn't stick a vice on it or anything, but it looks a handy enough piece to roll around the shop!

more fun making something from something you have recycled/restored/converted than just buying new things to make out of.I think pallets are great. Used for shelving and building racks to support thing's. Sure some are better than others but I find that theyare are great source of free wood to get creative with. My main problem is that I don't have a vehicle large enough to cart them around otherwise I would have loads of them. Mostly treated wood so great for outside use. Can take a bit of time dismantling them but that's half the fun...sort of...

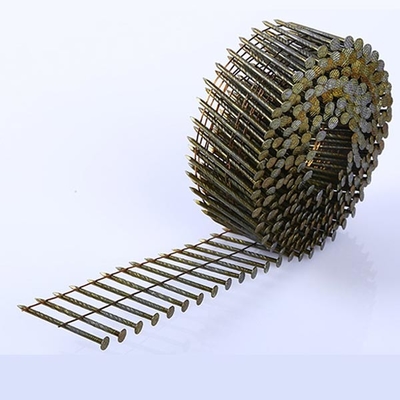

That is why they are called ring-shank nails, though the “glue” is almost certainly resin from the wood.The nails came out pretty easily, but they were a bit of weird, it looks like there is some kind of glue on them, and they have ridges on the shank,

You need to cut the shelf to length!!Fitted the drawing this morning.

View attachment 144175

Will say that the pine is very fragile, so keep a bottle of thin superglue handy. I cracked the drawer front when carefully paring the sockets for the half blind dovetails.

Enter your email address to join: