tool613

Established Member

The Wadkin trenching head is there version of the NA stacked dado. More like a tenon head though with bolt on knifes 1/2" thick. I first saw one in a wadkin tooling catalog Matty had and was intrigued. Than Matty told he had one and it was scary. When Matty tells you tooling is scary you best believe him.

after getting the Wadkin CC i thought i would try to hunt one down and found one on E bay UK.

now what i did not know is that this head is too small for the Wadkin CC cross cut saw. there heads are 11 3/4 round this one is 8.5. Any way i did not pay much for it and so i am still looking for the larger one.

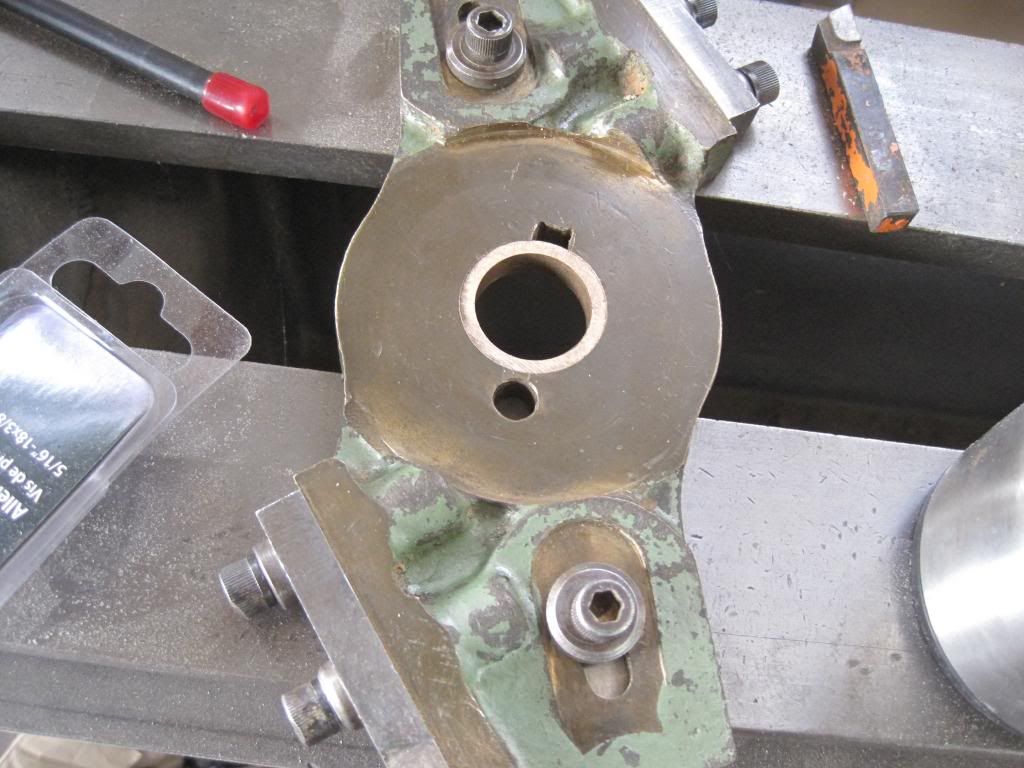

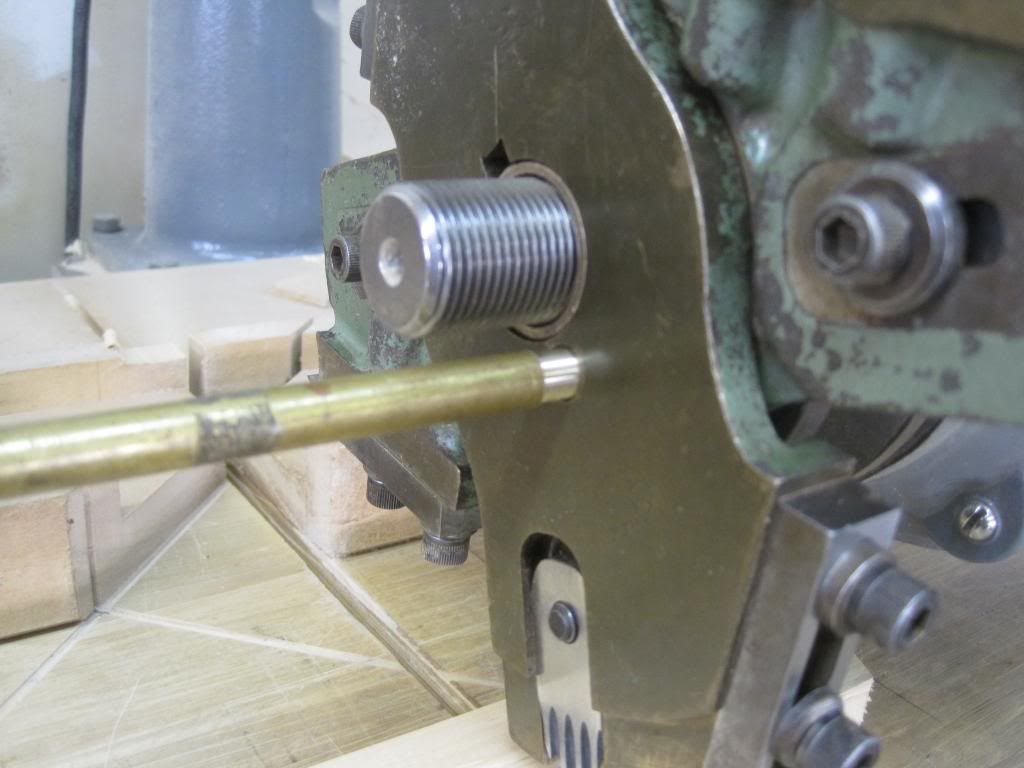

The head is sold bronzes and is a 1 1/4" bore with key way and pin drive. the head is expanding by the use of spacer between the two halfs. i sill have yet to make those. As is its smallest is 11/16 wide and will widen to 1 1/4" with spacer. This head would work on my Delta 40c 14" RAS with 1" arbor,so i thought i would show you what i did to covert it for use on that saw.

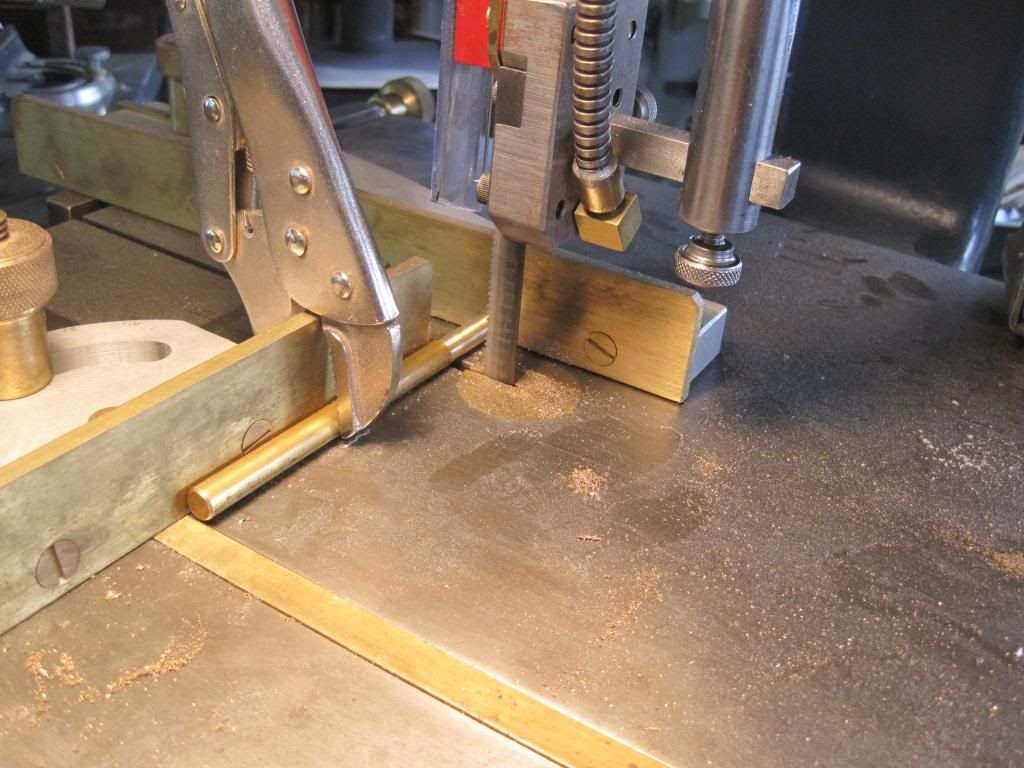

first i bushed the bore with a bronzes plane bearing 1 1/4 to 1" off the shelf part from the bearing house and cut it to the plate thickness on my Speedxa bandsaw. I then pressed pressed them in.

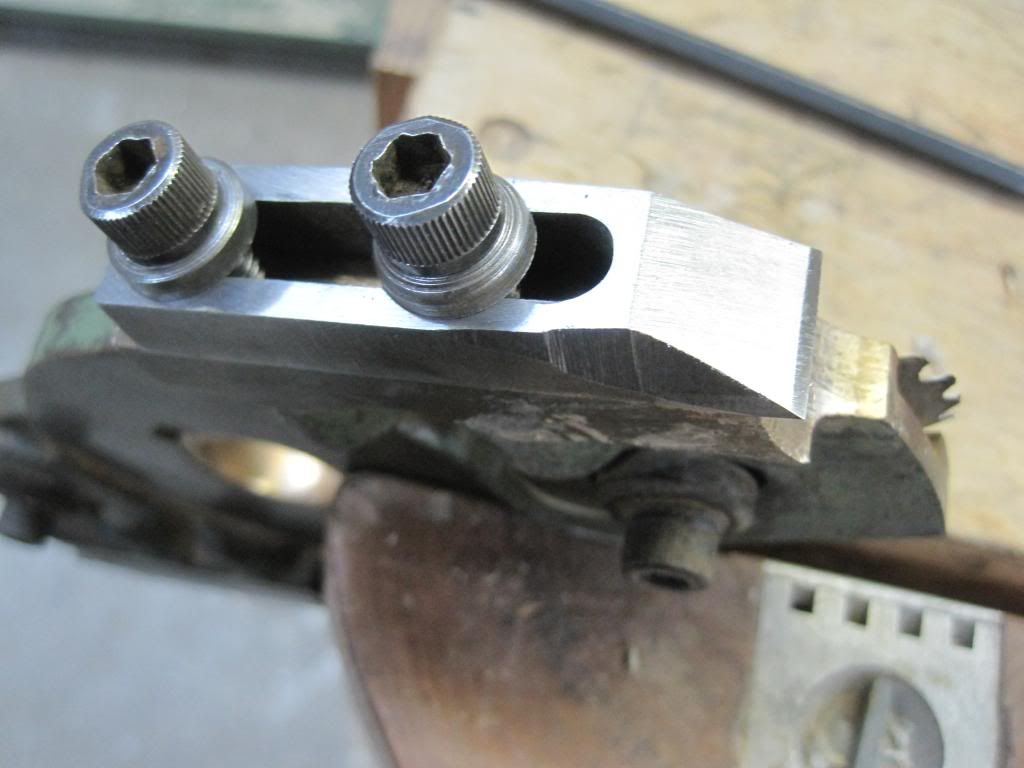

Next was to clean and resharpen the tooling. I took a knife and marked the location of the knife before i took it off .

laping the back

the cutters a mild steel that are tipped with HSS.

i lapped the bolts side and flattened the washers. very important to hold bolt down knifes.

see next post

after getting the Wadkin CC i thought i would try to hunt one down and found one on E bay UK.

now what i did not know is that this head is too small for the Wadkin CC cross cut saw. there heads are 11 3/4 round this one is 8.5. Any way i did not pay much for it and so i am still looking for the larger one.

The head is sold bronzes and is a 1 1/4" bore with key way and pin drive. the head is expanding by the use of spacer between the two halfs. i sill have yet to make those. As is its smallest is 11/16 wide and will widen to 1 1/4" with spacer. This head would work on my Delta 40c 14" RAS with 1" arbor,so i thought i would show you what i did to covert it for use on that saw.

first i bushed the bore with a bronzes plane bearing 1 1/4 to 1" off the shelf part from the bearing house and cut it to the plate thickness on my Speedxa bandsaw. I then pressed pressed them in.

Next was to clean and resharpen the tooling. I took a knife and marked the location of the knife before i took it off .

laping the back

the cutters a mild steel that are tipped with HSS.

i lapped the bolts side and flattened the washers. very important to hold bolt down knifes.

see next post