Thought I would post a few pics of progress for those who like such stuff. It's mostly just painting. And Sanding. And painting. And cutting off the odd drip with razor blades while thinking about painting it a bloodygain. etc etc etc... :| (

Dooo try to stay awake at the back).

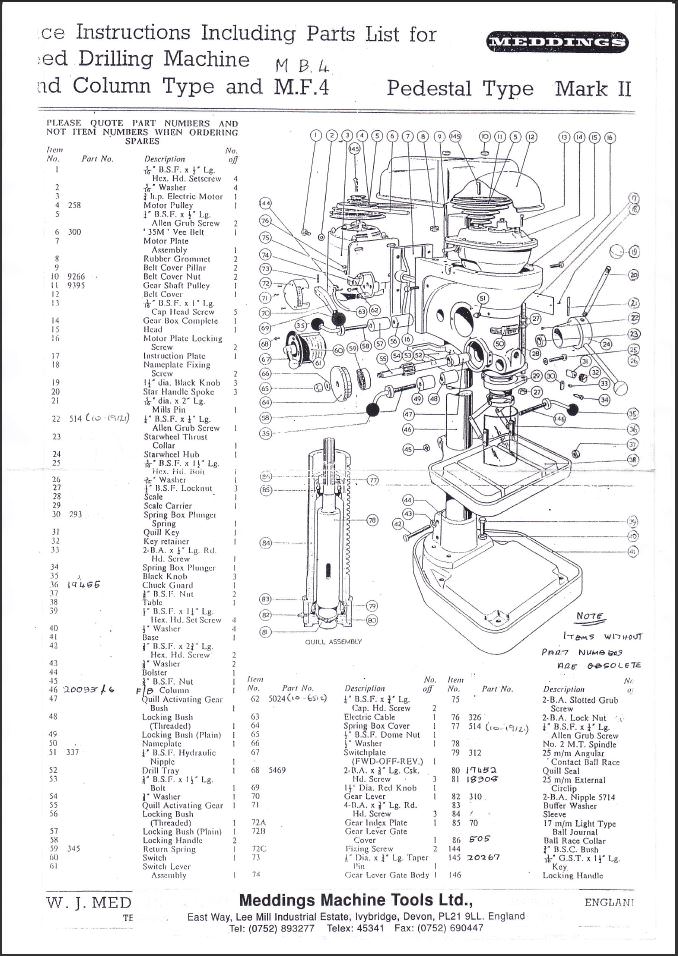

I won't include any advice on anything because obviously, as we all know I don't a bleedin' clue what I'm doing. Relying mostly on blind optimism, beginners luck and asking daft questions in other threads such as this one for cutting threads on the new arms.

cutting-threads-on-new-arms-for-meddings-imp-metric-info-t107292.html (More on that later).

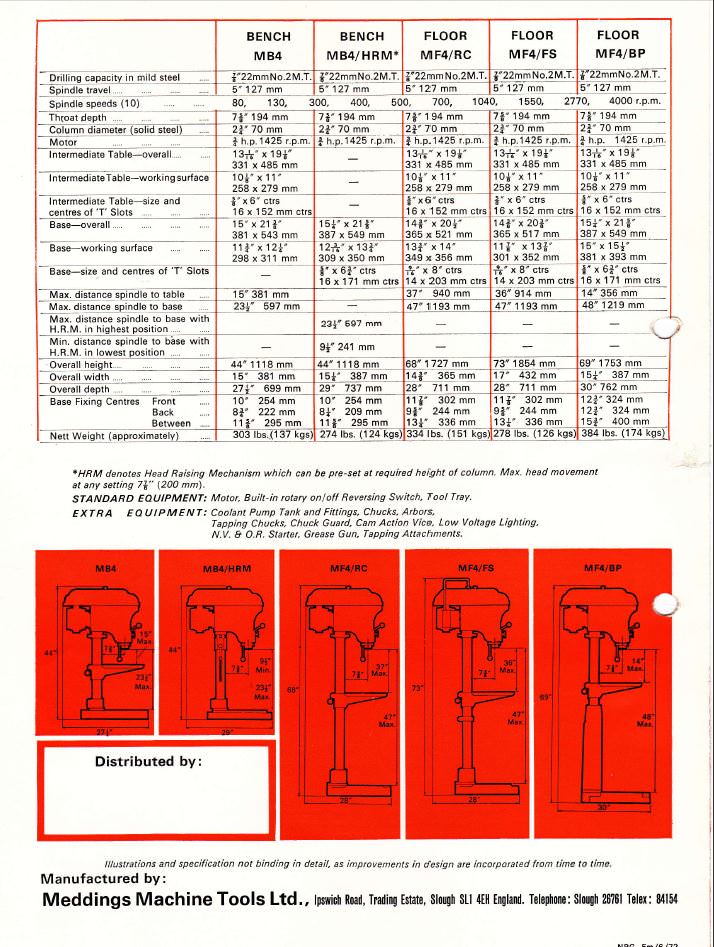

Let's get any semi technical info out the way. Started off with a Euro car parts primer to try and save money. Mistako Biggo. What I should have done was spend the money on the Craftmaster gear in the first place. I'd never seen Craftmaster on here as far as I recall but took a gamble because the website is eminently sensible. Of course there's vastly more experienced types on here who could have told me that or given other options but I didn't find it or know to look for it.

Turns out the Craftmaster paint is a joy to use as I'm sure are several other brands/types of paint. O

Onwards and upwards. Let's smash through these like some neighbours holiday slideshow you don't like but don't want to offend either.

'Here's Margo and I at the Parthenon, I

think we were the first people there that day

weren't we Margo? Magnificent. Simply Magnificent. Another dry sherry?'

Gittin' started. Thanks Workmate.

Very nearly

Left It Like This and painted an epic WW2 dogfight on it. If I could paint Epic WW2 dogfights and Spitfires and Me109s I actually would have done. Shame.

Filler an' that. Upol. Nasty gear, hate it. Annnnnnnd I've gone off in 3 seconds. FU upol. The skirt was added by a previous owner, not sure why. Lazy Monkey. Easier to leave it there than fill holes in metal by removing. :-"

Irritating the Mrs by getting paint on her Ferns. Oops.

Did a tiny review of this Hammerite gear, Kurust. Not a fan of the paint personally but this gear is top notch. Wipe on, wait for it to go black. Paint it. Job done. Ideal where it won't be seen.

*Next slide please Margo.

Couldn't get the rear fly wheel off the motor for love nor money. In the end had a moment of simpllicity and took the mountain to Mohammed. Upside down in the diptank. Nice.

Sweet.

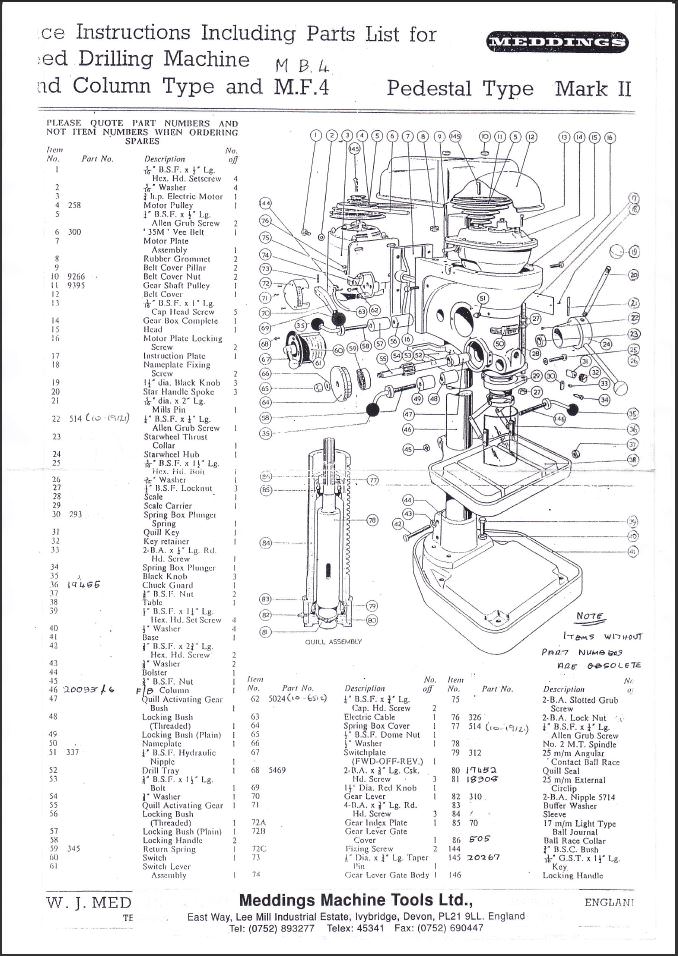

Original arms on the starwheel before I decided to stop being a donk and do it properly.

Which led to a whole new thread, lots of help and kindness. Thanks as always. You know who you are.

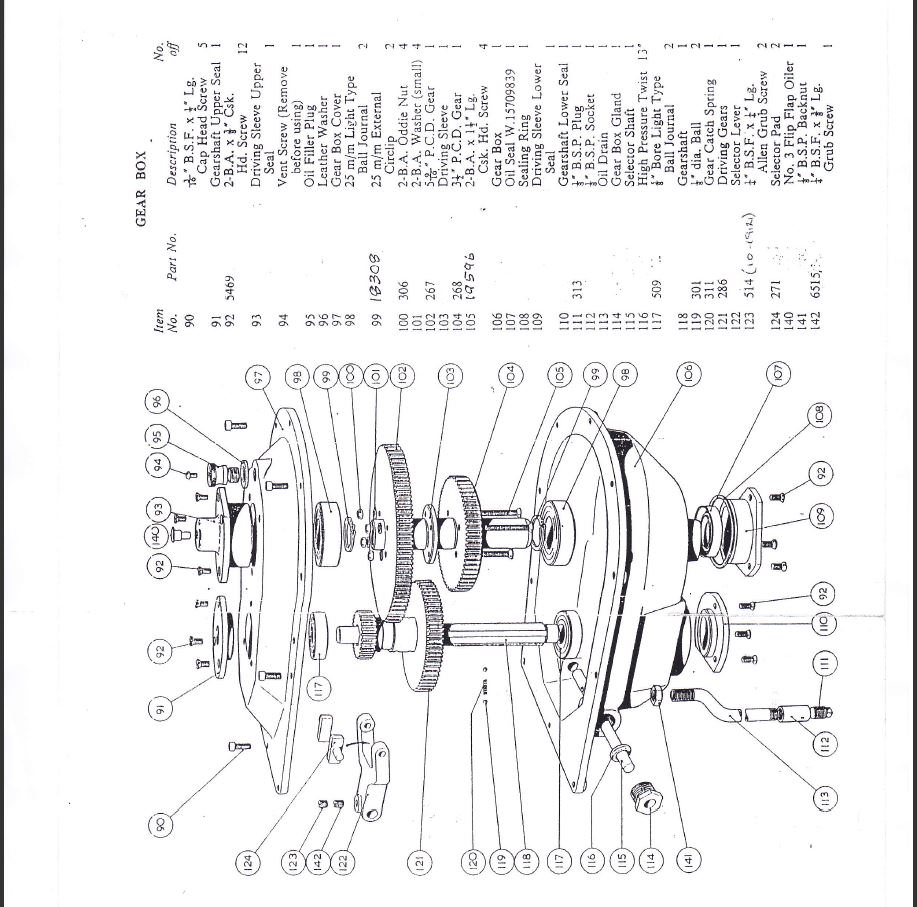

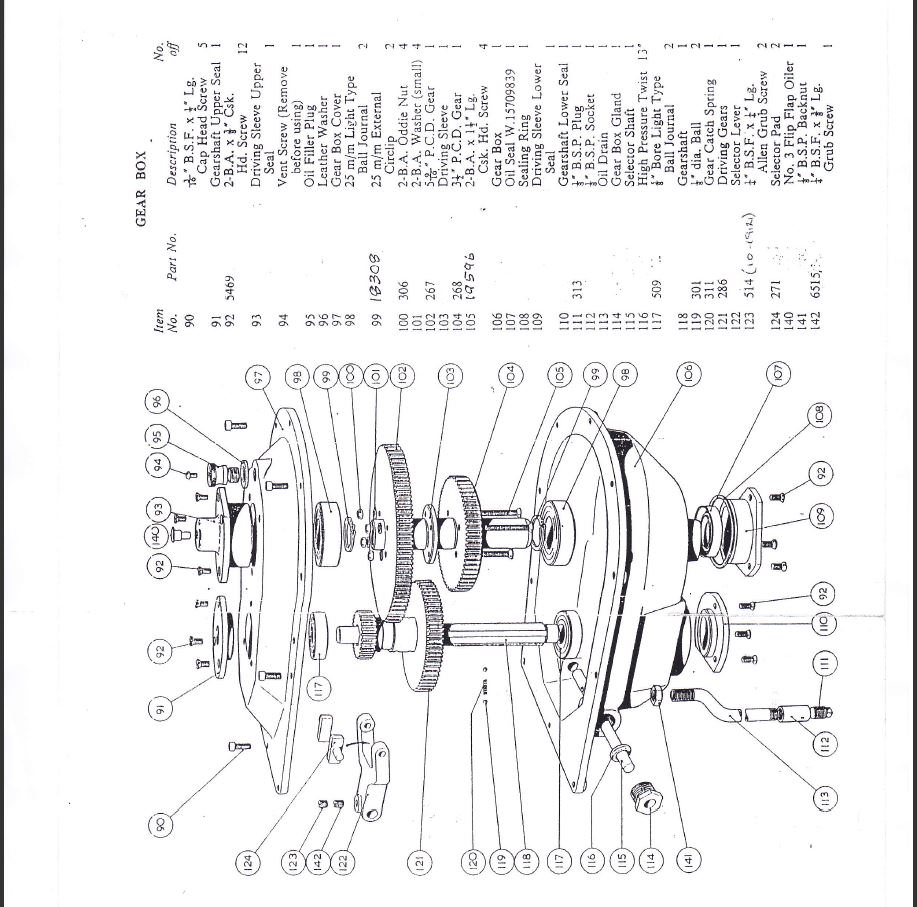

Incidentally. Searching for hard black balls is an eye opening experience on the internet. Try WDSltd instead. Being Imperial (I'm learning) I got my hard black balls undersized and tapped them out with my bsf tap. Bosh.

Next Slide Margo. Margo? Margo's popped off to the ladies room for a moment. :shock:

More painting.

Meanwhile, the Myford Grey had turned up to join the Colchester Dove Grey. (Yaaaaawn.)

Cut the missing hex bolt on the clarkey down to size. Woooo!

Gittin' fancy pants with the painting yo. Margo's back looking flushed.

Managed to heave the drill head onto the column and painted bits today so I can finish that. Had a moment where I thought my eye would pop out while holding it and trying to get the clamp in place with my fu****g eyebrow.

:| Turns out I'm quite sweary.

I have a question. Don't think I posted all them photos for nothing did you?

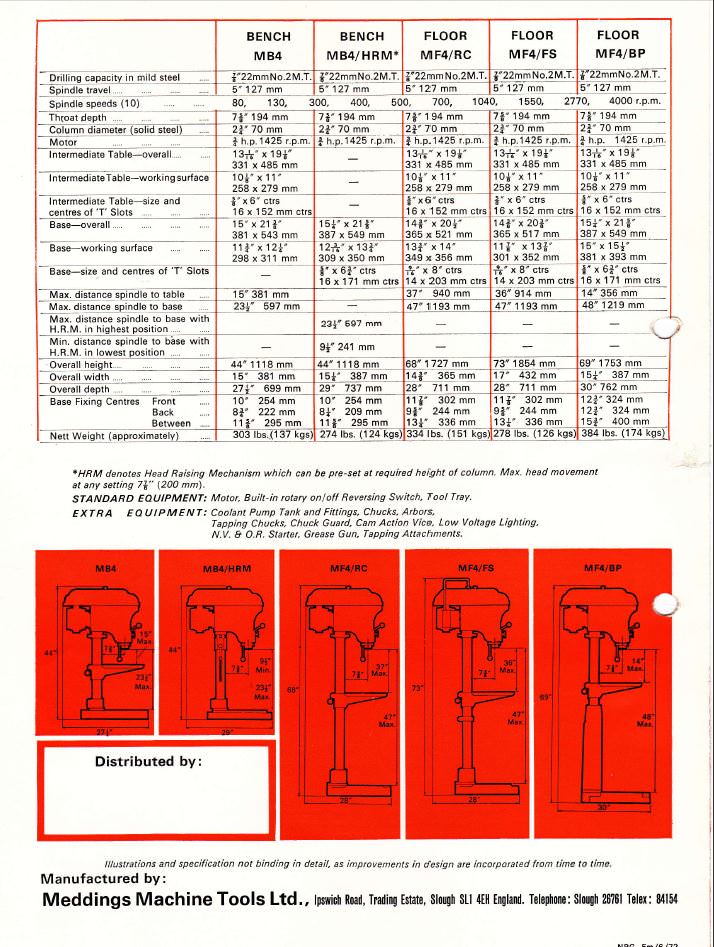

The seller told me the reverse is borked.

Mindthatwhatouch mentioned that reverse is done electrically.

My grasp of motors is fundamentally basic. Wiring miss connection, fault with motor, what's that white bit. Could replacing it help. Please excuse what I humbly recognise is a huge lack of knowledge.

As always. Glad of any bones you could throw me.

Thanks as always for looking at my daft attempts and preposterous lack of technical ability.

All the best,

Chris

(slightly edited for for a couple of typos)