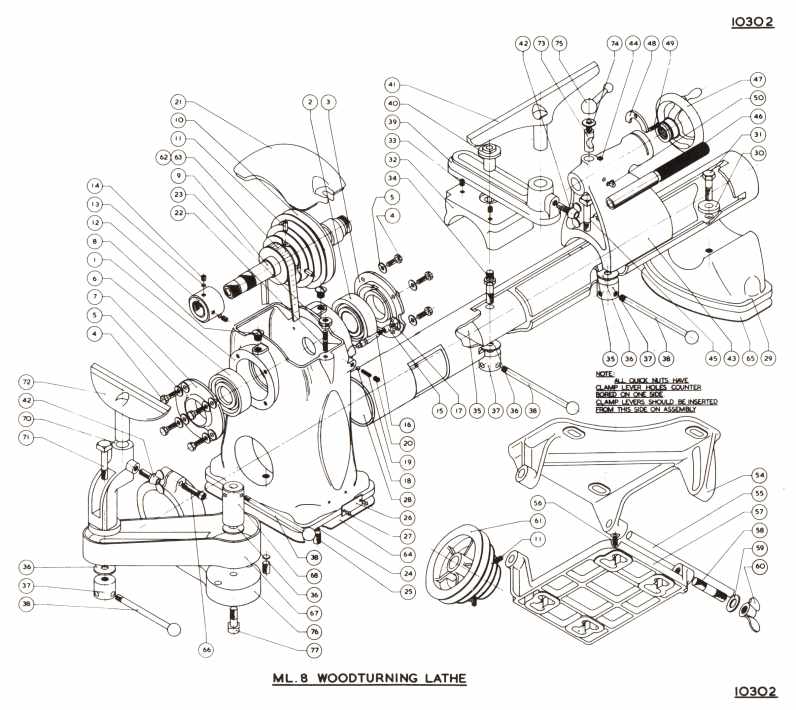

Hello I have a Myford ML8 wood turning lathe. it was gifted to me with a band saw attachment and a few other bits and bobs, my problem is the tailstock hand wheel is broken. The tailstock is all there apart from the hand wheel. does anybody know the size of the thread, so I can have a go at making one ? or anywhere I could buy one. It is the early cream coloured lathe. Thanks in advance, Simon,

P.S. any info on inter-changeable parts, chucks... etc. would also be handy.

P.S. any info on inter-changeable parts, chucks... etc. would also be handy.