I have been using Moxon vices for many years ... I've cut many dovetails for many years. As a result of this, I am at pains to advice all NOT to either build a "Moxon" (it is a double screw vice and not a Moxon) into the skirt of a bench. Also do not build a table behind the vice.

Why? Because ... when one transfers tails to the pin board, and the top of the pin board lies flush with the chop, the knife used to score the marks will slice into the chop and eventually mark it up terribly. Being careful will not prevent this.

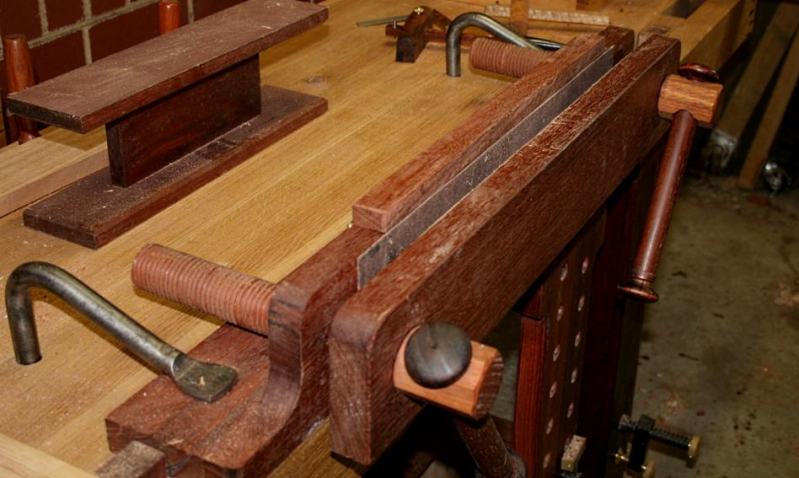

It is the reason why the pin board needs to be lifted above the chop. And to do this, I use a spacer on the chop. Eventually, I built the spacer into the back of the Moxon. This is seen in the last of my photos in my earlier post.

My current Moxon vice, which I nicknamed "The Last Moxon Vice" (meaning the last one I shall build), takes this a step further.

The spacer is at the rear ...

... and folds down when not in use (such as when sawing). You want the boards as low as possible when sawing to reduce any vibration.

One could just use the spacer to raise the work and transfer marks ...

But, especially with wider boards, the spacer has a built-in track to clamp down the tail board to make marking more secure ...

Other details include rubberised cork inside the chop ...

... and springs inside ...

The idea for springs came from David Barron, but I have used triangular types (rather than the parallel type David used), as these collapse into themselves to close up.

As you loosen the wheels, the chop opens up ...

A photo of this Moxon vice was published by Fine Woodworking Magazine a few editions ago.

Regards from Perth

Derek