tool613

Established Member

used a wood cutting 2 flute 1/2" straight carbide bit. I was going to use an end mill but thought it would be less grabby. After the first cut i turned the speed up a bit and the cut improved big time. I was taking about .025 cuts with great control. the bit is still good after cutting the iron too. I thought i would go for the 60 to 70 SFPM cutting speed but found it too slow for hand held work. This was to clean up the opening in an Oliver 190 bottom scroll sander. Really surprised at how crude Oliver left it.

Speeds are guess as i am using a rheostat to control the speeds.4000 rpm for 1/2 cutter worked best for me but in the video running about 1000 rpm and not the 600 SFPM i mention. I did no have to sharpen the bit but i did turn the speed up on the last cut and took off about .010.though this rheostat is for motors this size. Its got a knob 1 to 10 and i just used my best guess at the numbers on the dial and what i know by sound. I know what my router sounds like with speed control built in and at it lowest speed is 9000 . I look at it spinning to guide my speed as well. That all said i really used control and milling quality to make my adjustment to the speeds. The chips were not blue or hot hitting my bare arms. I am by no means suggesting any one try it . it just what i did with my limited tools. it was a lot easier than i though it would be. As a note i measured the depth and from corner to corner it was within .003"

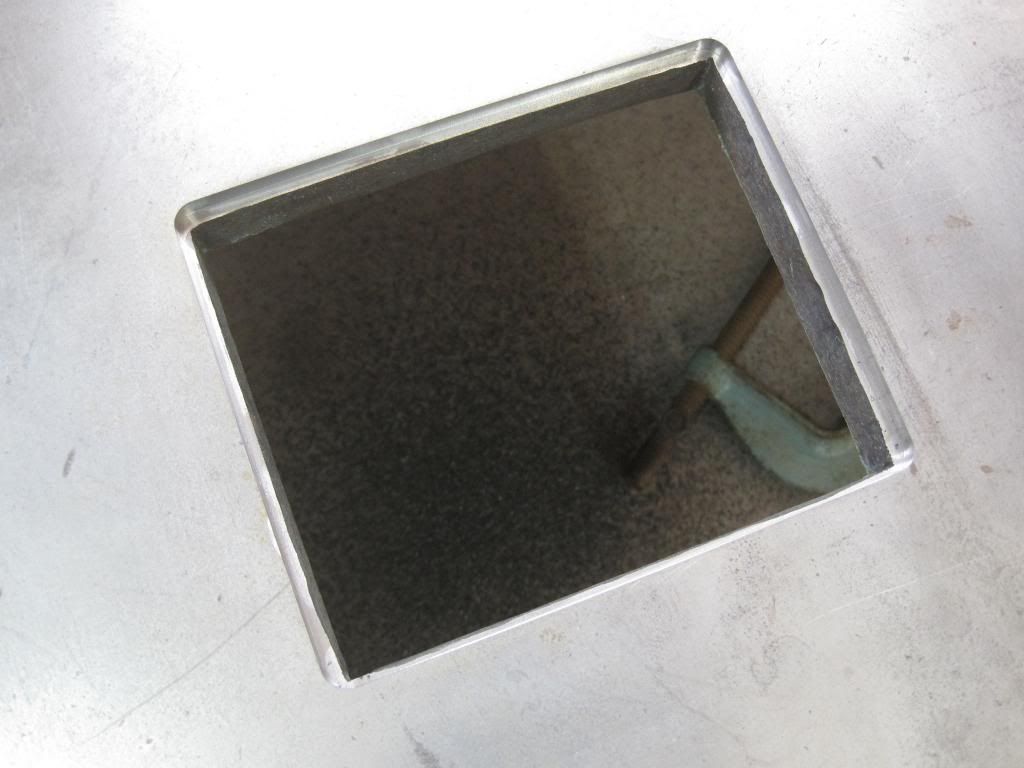

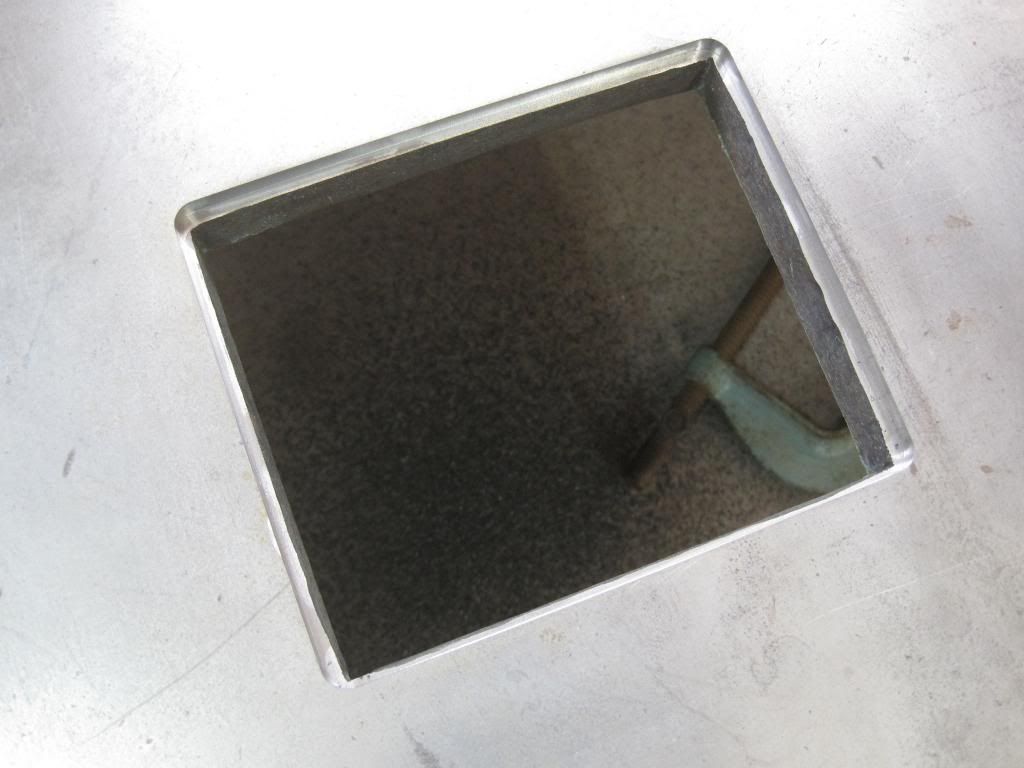

simple jig clamped well.

opening to mill the 1/4 x 1/4 rabbit in for a table insert

took about 15 mins to cut to the depth

made a movie of it

http://www.youtube.com/watch?v=-iCWdG8FyMU

jack

English machines

Speeds are guess as i am using a rheostat to control the speeds.4000 rpm for 1/2 cutter worked best for me but in the video running about 1000 rpm and not the 600 SFPM i mention. I did no have to sharpen the bit but i did turn the speed up on the last cut and took off about .010.though this rheostat is for motors this size. Its got a knob 1 to 10 and i just used my best guess at the numbers on the dial and what i know by sound. I know what my router sounds like with speed control built in and at it lowest speed is 9000 . I look at it spinning to guide my speed as well. That all said i really used control and milling quality to make my adjustment to the speeds. The chips were not blue or hot hitting my bare arms. I am by no means suggesting any one try it . it just what i did with my limited tools. it was a lot easier than i though it would be. As a note i measured the depth and from corner to corner it was within .003"

simple jig clamped well.

opening to mill the 1/4 x 1/4 rabbit in for a table insert

took about 15 mins to cut to the depth

made a movie of it

http://www.youtube.com/watch?v=-iCWdG8FyMU

jack

English machines