Philly

Established Member

Aww...you guys :lol:

Simon - good chance I won't beat you :wink:

Philly

Simon - good chance I won't beat you :wink:

Philly

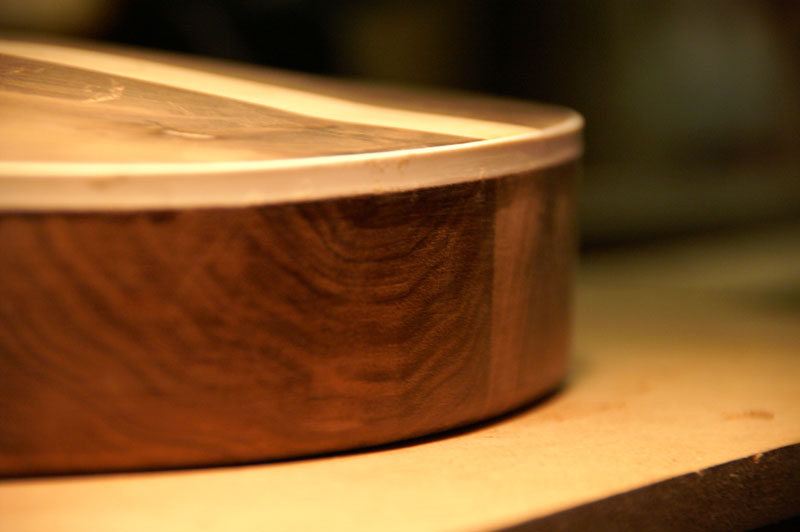

Philly":2rx8q9pn said:Great stuff, Simon! They look awesome - can't believe you guys haven't splashed some finish on them yet to see the figure pop :lol:

mrbingley":1tntemhb said:Hi Bainzy,

Doesn't my username help with my location :wink: , Or were you asking which part of town I live in ?

Thanks for the offer of the templates, I'd like to take you up on that.

Cheers

Chris.

Ironballs":2g0ifyd5 said:Okay ta, might have a wander over to Boddy's at some point. Saw there was a luthier supplier over in Manchester as well that could be worth a look.

General question, do you know what Dragon Timber in Stanningley are like? ie do they stock decent quality hardwoods and do they let you have a rummage through their stock

Slim":1962w27e said:You need to think about the cost as well. Although, it will be significantly cheaper than buying a Gibson, my build will probably cost in the region of £300. The satisfaction of building your own, though, will be priceless.

Did you not try adjusting the truss rod?stef":1xeg8fsh said:Slim":1xeg8fsh said:You need to think about the cost as well. Although, it will be significantly cheaper than buying a Gibson, my build will probably cost in the region of £300. The satisfaction of building your own, though, will be priceless.

I was also thinking about building my own axe, i had the SG or the les paul in mind.

However,i disagree with you on the cost issue.

if you want Gibson standard, you will need over £200 worth of pickups, another 50 in potentiometers, switches, plugs, another 150 in bridge + tuning keys... that 400 already and you havent even touched wood yet !

i'd estimate the costs to be very near a decent second hand buy... without the knowledge that the guitar will be spot on.

Having just bought a 2nd hand epiphone SG, i know too well how tricky it is to get a neck/fret board/body right.

(my SG was slightly bowed, which required me to 1-raise the action 2- redress the frets above the 12th. it is still bowed and the action is still high. it would need a replacement neck. i forget to mention that the action is measured at 2 to 8 64th of an inch. that is a very, very very tight spec for any wood worker, let alone average joe like me in his workshop !

factor in wood movements under the stress of the strings, and you really appreciate the experience required to become a guitar maker !

i dont question your abilities, but i think you will accomplish a miracle if you manage to get something comparable to a original gibson.)

that was just talking on the cost effectiveness of the approach though... not questionish the pleasure you do get out of it ! that goes without arguements !

They look beautifull though... so keep up the good work !

bob_c":2ju8vsiw said:Did you not try adjusting the truss rod?

Enter your email address to join: