Quick question.

Need to make garden gate and was going to make it with rails (3) and stiles (2).

M & T joints.

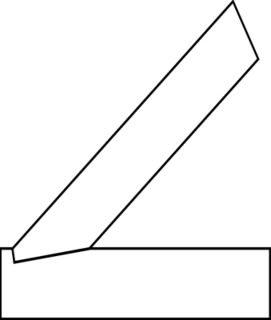

I wanted to fit diagonal braces between rails and wondered how to joint these.

Do I incorporate the diagonal into the M & T joints at the corners?

Tried to draw a pic on sketchup but I'm rubbish.

Need to make garden gate and was going to make it with rails (3) and stiles (2).

M & T joints.

I wanted to fit diagonal braces between rails and wondered how to joint these.

Do I incorporate the diagonal into the M & T joints at the corners?

Tried to draw a pic on sketchup but I'm rubbish.