Jervisekken

Established Member

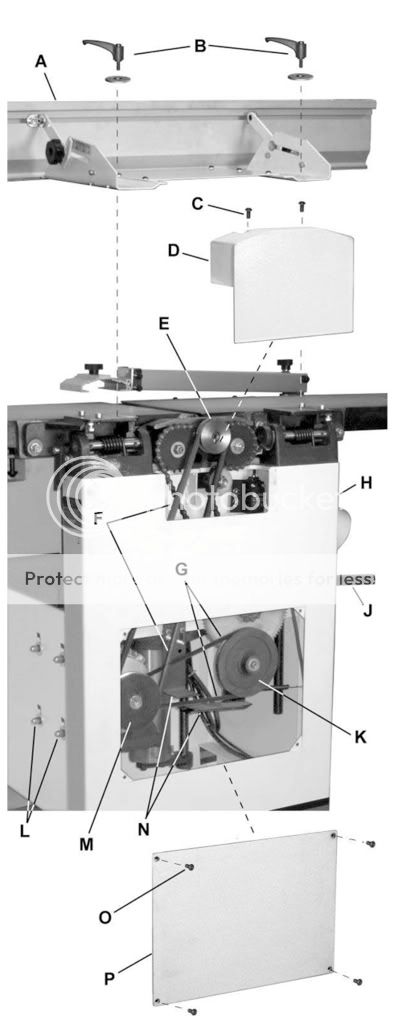

I've got a Jet planer/thicknesser combination machine.

unfortunately I tried to thickness a workpiece that was way too thick and it got stuck. I managed to get it loose but now the machine has these symptoms:

1. there is an odd sound when running the machine

2. the steel roller that feeds the workpiece in thicknessing mode is jammed and not moving, i.e. I can not thickness,

I have of course been in contact with the supplier of the machine but it will take some days to get a technician here to look at it.

Does anybody have advice?

unfortunately I tried to thickness a workpiece that was way too thick and it got stuck. I managed to get it loose but now the machine has these symptoms:

1. there is an odd sound when running the machine

2. the steel roller that feeds the workpiece in thicknessing mode is jammed and not moving, i.e. I can not thickness,

I have of course been in contact with the supplier of the machine but it will take some days to get a technician here to look at it.

Does anybody have advice?