devonwoody

Established Member

I have got family visitors (holidays) staying a few days, so things have come to a stop.

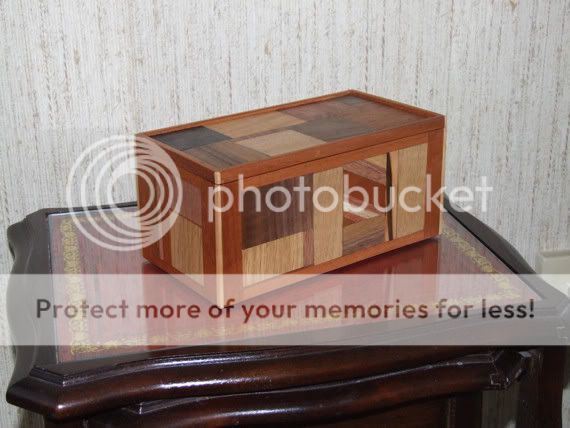

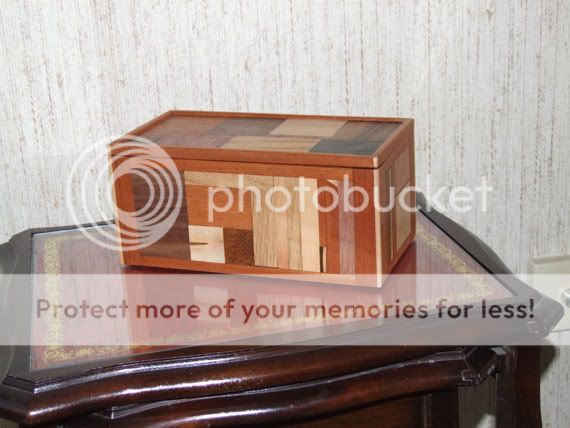

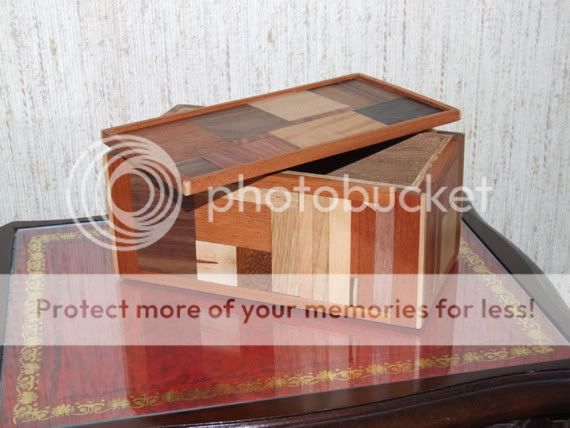

I have a box in progress at the moment , the first as a trial run. So I would be quite happy to make a further box using donated pieces.

So shall we say using donated pieces after 21 st Aug.

I have a box in progress at the moment , the first as a trial run. So I would be quite happy to make a further box using donated pieces.

So shall we say using donated pieces after 21 st Aug.