Hello,

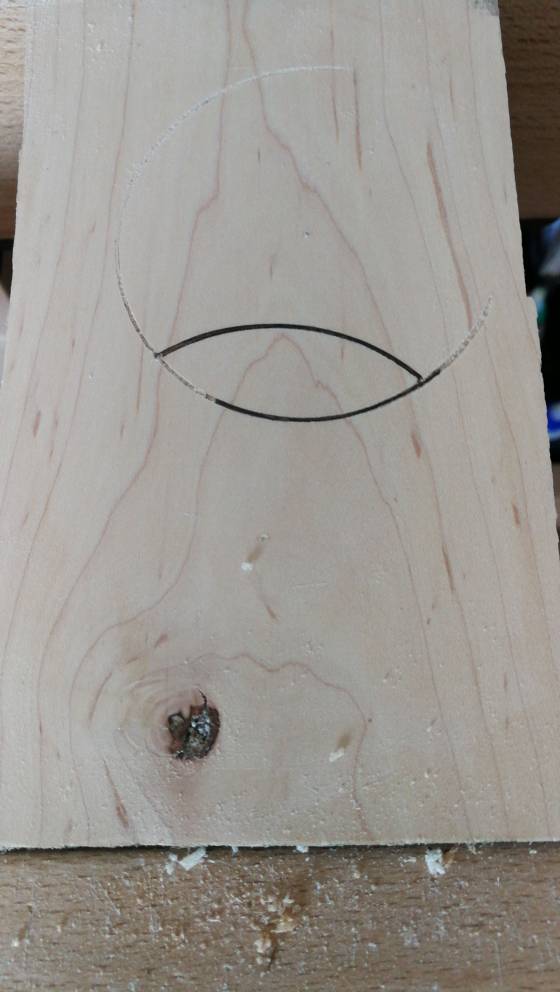

I would need some help/clarification on inlaying bandings. I watched the video from Steve Latta (quite well made) but the following is a bit unclear :

I would use some veneer (no bandsaw yet...), and as stated in the video, veneer is most of the time too thin. It is advised to laminate 2 or 3 sheets of veneer to get a thickness of 1,5 mm (in this ballpark), before slicing it and apply it in your groove.

Where im very confused : Should the veneer thickness be equal to the width of your groove (in that case the veneer woulb be glued "on the side") or should the width of your veneer equals the width of your groove ?

In the first case, isnt there a risk that the veneer lamination shows up ?

In the second case, what is the use of the thicknessing gauge ? (https://www.lie-nielsen.com/product/too ... ?node=4180)

Thanks for your advices! (and I hope what i said makes sense !)

Christophe

I would need some help/clarification on inlaying bandings. I watched the video from Steve Latta (quite well made) but the following is a bit unclear :

I would use some veneer (no bandsaw yet...), and as stated in the video, veneer is most of the time too thin. It is advised to laminate 2 or 3 sheets of veneer to get a thickness of 1,5 mm (in this ballpark), before slicing it and apply it in your groove.

Where im very confused : Should the veneer thickness be equal to the width of your groove (in that case the veneer woulb be glued "on the side") or should the width of your veneer equals the width of your groove ?

In the first case, isnt there a risk that the veneer lamination shows up ?

In the second case, what is the use of the thicknessing gauge ? (https://www.lie-nielsen.com/product/too ... ?node=4180)

Thanks for your advices! (and I hope what i said makes sense !)

Christophe