Chris Knight

Established Member

I want to make a dressing table with a mirror that rises out of the cabinet - similar to say a flat screen TV, so that in the closed position, the top of the dressing table is flush.

I'd use a TV lift if I had enough height in the cabinet but unfortunately, I don't (the motor etc adds considerably to the amount of movement these lifts create) I have a 70 cm height in the dressing table and I need a 60 cm extension.

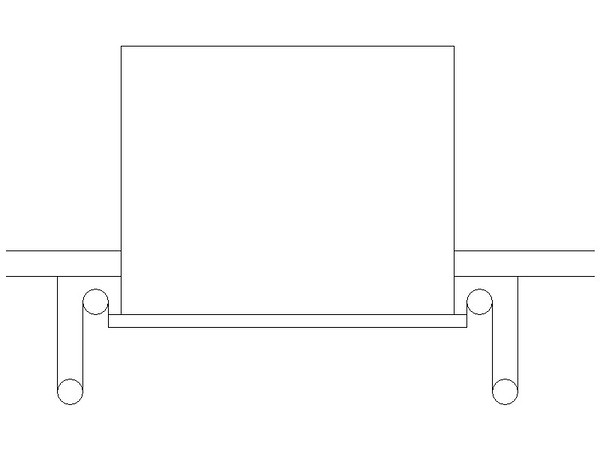

I have an idea for doing it by mounting the mirror on frame carried on full extension drawer slides and am looking for advice on a high quality, robust drawer slide suitable for this purpose.

I think the drawer slides will have to be used behind the mirror and obviously, they will be used vertically rather than in the normal horizontal position - I had thought of using rails with linear bearings but you can't get these as full extension devices and the cost is very high.

Perhaps folk who use these drawer slides can tell me how flexible/strong a couple or even three are likely to be when used in the way? The mirror itself is not too heavy - probably 15 pounds at max.

I'd use a TV lift if I had enough height in the cabinet but unfortunately, I don't (the motor etc adds considerably to the amount of movement these lifts create) I have a 70 cm height in the dressing table and I need a 60 cm extension.

I have an idea for doing it by mounting the mirror on frame carried on full extension drawer slides and am looking for advice on a high quality, robust drawer slide suitable for this purpose.

I think the drawer slides will have to be used behind the mirror and obviously, they will be used vertically rather than in the normal horizontal position - I had thought of using rails with linear bearings but you can't get these as full extension devices and the cost is very high.

Perhaps folk who use these drawer slides can tell me how flexible/strong a couple or even three are likely to be when used in the way? The mirror itself is not too heavy - probably 15 pounds at max.