A

Anonymous

Guest

:lol: Showing off ant I.

no. I never had reason to do it before, and I thought it was interesting , so I decided to write about it since I took some photos and I can't sleep.

Cleaning up some old cedar doors at the moment. Cedars was as common as plywood is today around my parts.....I even heard it was once well exported to the UK from forrestry near to my home. So its everywhere.

For some strange reason someone decided to paint these bueatiful cedar french doors with white paint and I've been asked to strip the paint......hellova job. It doesn't look good unless ALL the paints removed, and I don't like using chemicals. So scrape and re-plane etc and fingers crossed.

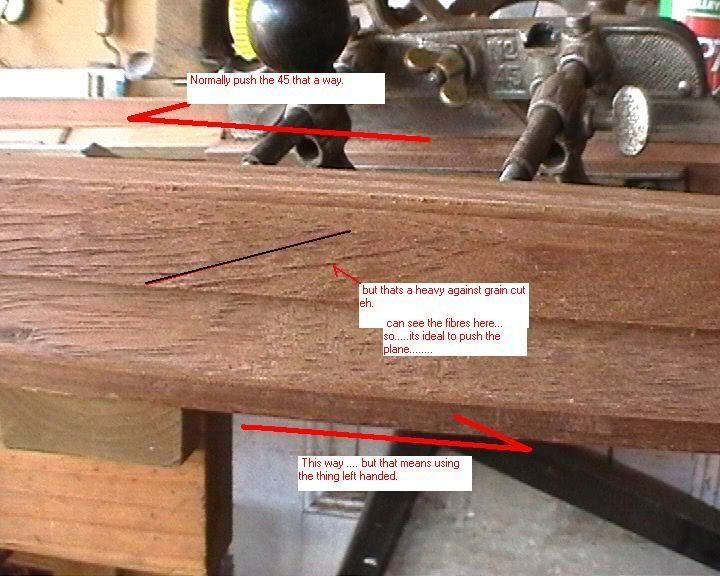

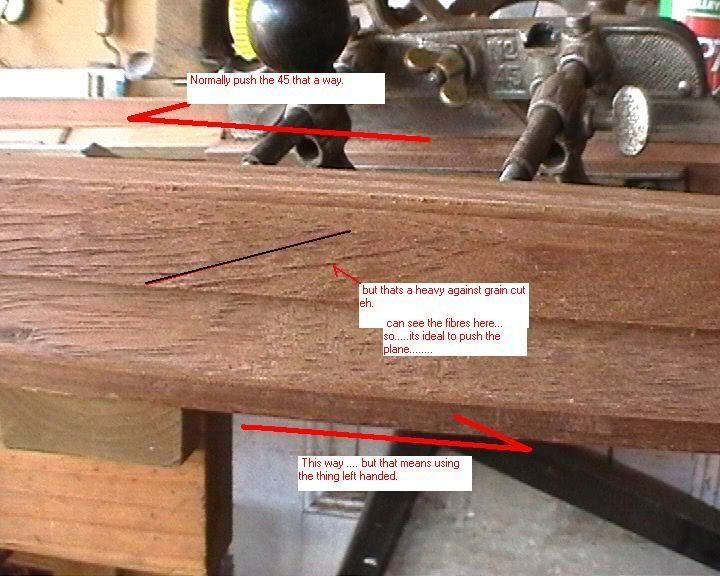

Anyway, since its already jointed I don't have the luxury of arranging the pieces for ideal grain cuts......and I have to reform a bead that runs along the edge of the door.

But the sprouts aggressively against grain for my normal stanley 50, which is my regular plane for such cuts.

And I realised I can't push the #50 left handed, since you can't reverse the fence........But you can with the stanley 45 I thought.

wacko. Learn somthing new everyday.

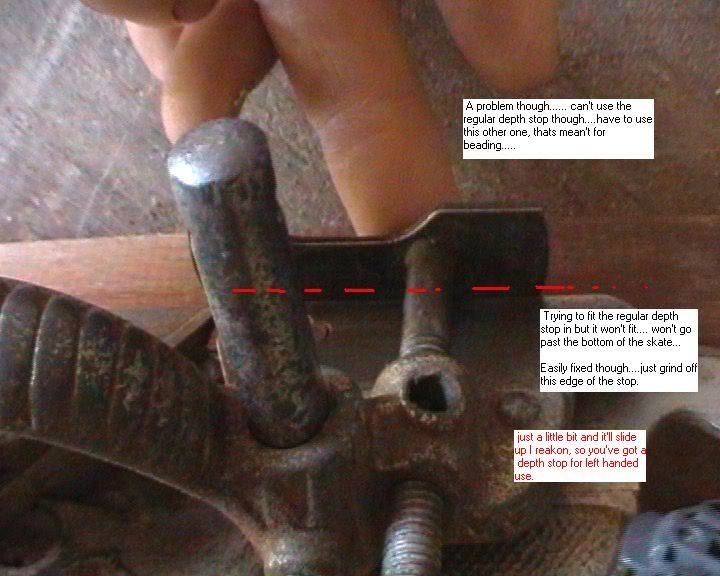

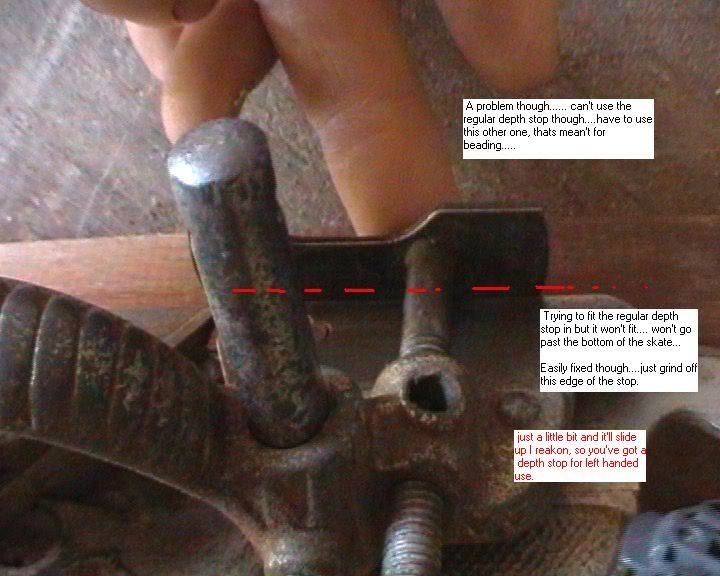

I didn't bother grinding the edge off the depth stop this time round.... no reason other than I didn't have to....so I just eyeballed it.....it wasn't critical that the bead have a consistant depth.....since the bead was leading to nowhere.....since its just a bloody door :roll: :lol: ( arn't these emoticons fun )

Very clean cut though, as you'd imagine when planing WITH this kind of grain. So it was worth doing.

no. I never had reason to do it before, and I thought it was interesting , so I decided to write about it since I took some photos and I can't sleep.

Cleaning up some old cedar doors at the moment. Cedars was as common as plywood is today around my parts.....I even heard it was once well exported to the UK from forrestry near to my home. So its everywhere.

For some strange reason someone decided to paint these bueatiful cedar french doors with white paint and I've been asked to strip the paint......hellova job. It doesn't look good unless ALL the paints removed, and I don't like using chemicals. So scrape and re-plane etc and fingers crossed.

Anyway, since its already jointed I don't have the luxury of arranging the pieces for ideal grain cuts......and I have to reform a bead that runs along the edge of the door.

But the sprouts aggressively against grain for my normal stanley 50, which is my regular plane for such cuts.

And I realised I can't push the #50 left handed, since you can't reverse the fence........But you can with the stanley 45 I thought.

wacko. Learn somthing new everyday.

I didn't bother grinding the edge off the depth stop this time round.... no reason other than I didn't have to....so I just eyeballed it.....it wasn't critical that the bead have a consistant depth.....since the bead was leading to nowhere.....since its just a bloody door :roll: :lol: ( arn't these emoticons fun )

Very clean cut though, as you'd imagine when planing WITH this kind of grain. So it was worth doing.