RogerS

Established Member

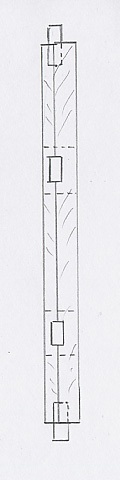

Some of the frame members at the cottage are rotten and need replacing.

Two cross beams and one upright.

The originals were tenoned and morticed into other parts of the frame but clearly I can't dismantle the entire Meccano kit so how can I carry out the repair?

There must be a way to do it without resorting to metal brackets etc but I can't see it.

Many thanks

Two cross beams and one upright.

The originals were tenoned and morticed into other parts of the frame but clearly I can't dismantle the entire Meccano kit so how can I carry out the repair?

There must be a way to do it without resorting to metal brackets etc but I can't see it.

Many thanks