RogerP

Established Member

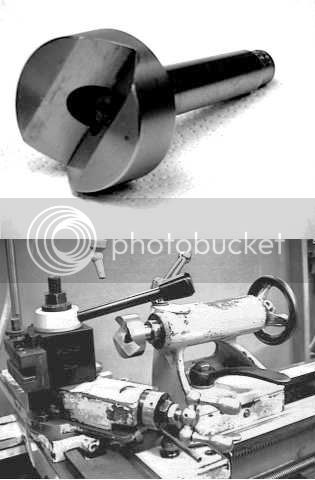

Take a short length (say 100mm) of 40mm diameter round tube with a wall thickness or 5mm.

What method would you use to bore a 15mm hole going through both walls perfectly centrally in all regards?

What method would you use to bore a 15mm hole going through both walls perfectly centrally in all regards?