BigShot

Established Member

Hi folks. Nice place you've got here.

Before I start, I know It's dirt cheap, massively inferior to anything more substantial and expensive and I'll really want a better one but the first point is key.

It was dirt cheap and that's the difference between me having a table saw in the foreseeable future and not, so let's leave that point aside and assume I'm using this saw and not going to be upgrading to a better one for a while yet.

Here we go. I bought a 1500W "Aldi Table Saw" this week (stock left over from when it went on sale last year). Once open the manual and ID plate say it is an Einhell PTS 15/250.

I've been measuring and messing with a few bits and pieces and have determined that with the table top as perfectly level as I can measure, the blade fully raised and perpendicular to the table top, the rear edge of the blade is closer to the left hand mitre track than the front edge is by about 1mm (0.039"). (I've used the same tooth as the reference point for both measurements)

Now, I believe most similar table saws have trunnions which are tweaked to align the blade properly, however this one isn't set up like that.

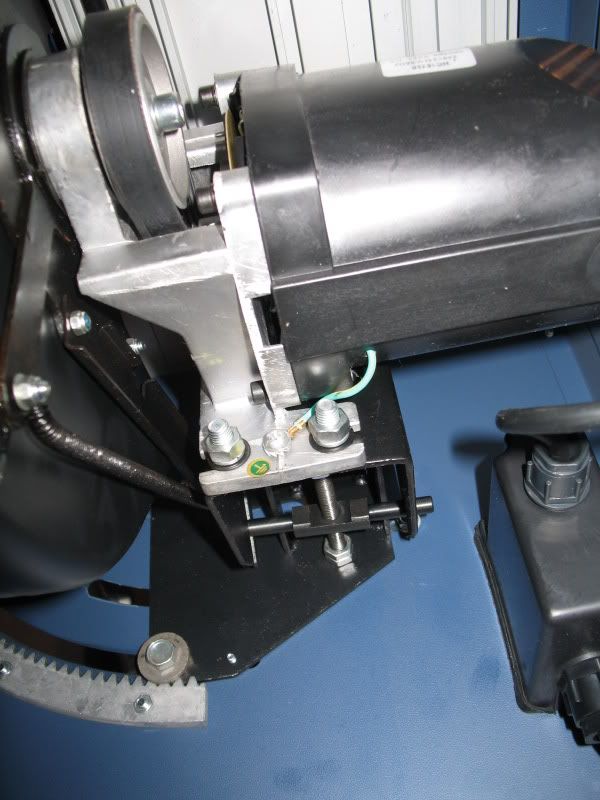

Here are a few pictures of the insides.

Inside from below the table with the blade at 90 degrees.

Note the 4 large allen head bolts at the top of the box section on the left side of the image.

Also note the black rod running along the centre of the table, this is the pivot for the blade angle.

Inside from below the table with the blade at 22.5 degrees.

Inside from below the table with the blade at 45 degrees.

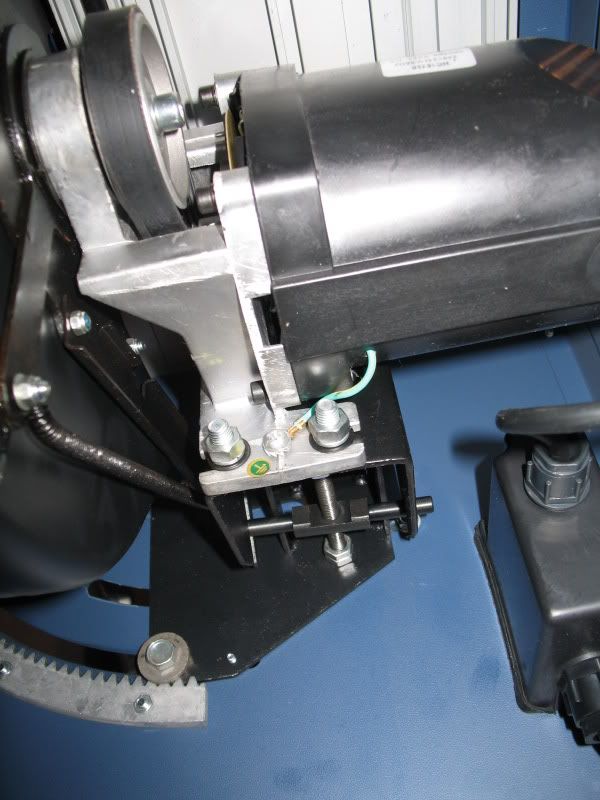

Angle and blade height mechanisms at 45 degrees.

Angle and blade height mechanisms at 90 degrees.

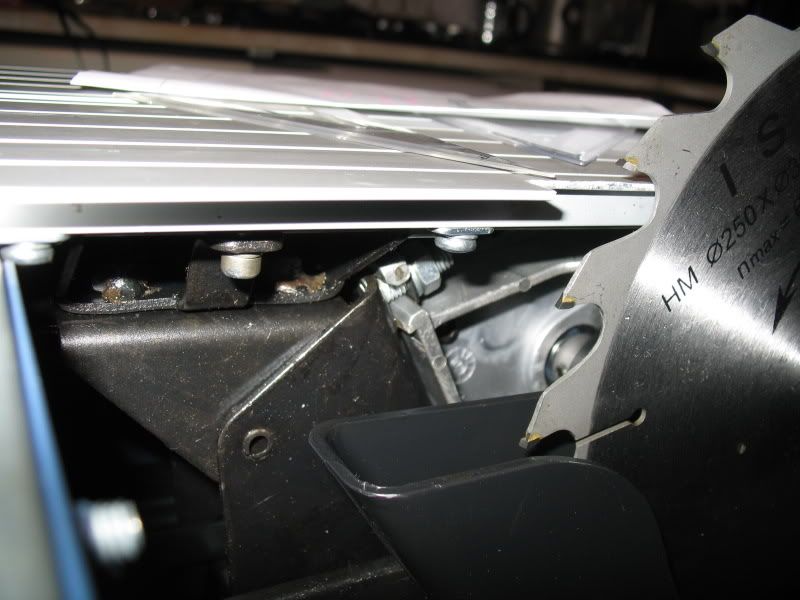

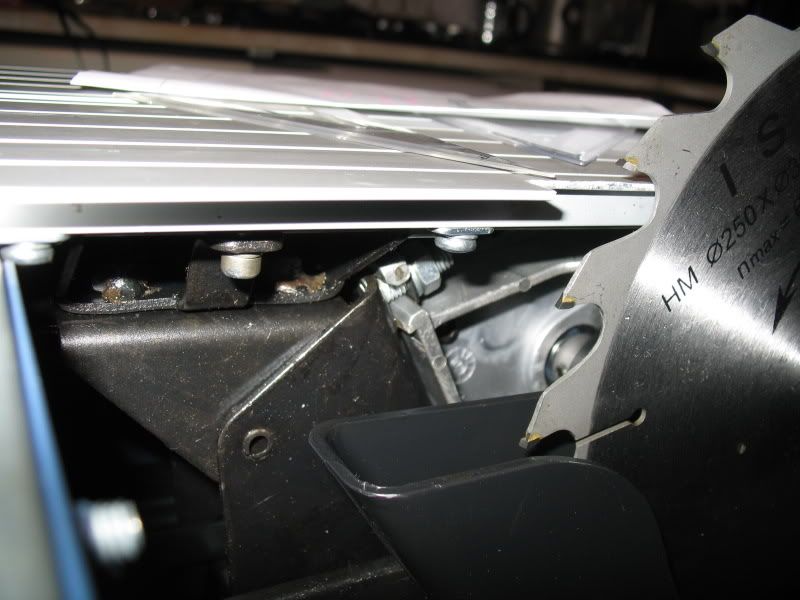

View through table to blade height pivot.

The bolts you can see immediately below the table surface attach the whole shooting match to the pivot bar you can see running under the table surface in the first three pictures.

The odd looking bits above the height pivot are welded in captive nuts which receive the four large allen bolts you can see in the left hand side of the first picture.

This is about the best I can do on the photo front.

So, any suggestions on how to align this thing?

Again, looking from the front of the machine, the front blade is approximately 1mm (0.039") closer to the left hand mitre track than the rear of the blade.

Measurements taken using the same tooth for both with the blade at full height. Also repeated using other teeth to be sure.

I'm sure many people would question the sense in trying to get a saw like this set up nicely, but I think that once it's done it'll be more than good enough for my purposes (well, once I've stopped the slop in the mitre tracks and made a few extra toys to use with it that is, but I digress...)

I'm looking forwards to your responses.

Cheers folks.

Before I start, I know It's dirt cheap, massively inferior to anything more substantial and expensive and I'll really want a better one but the first point is key.

It was dirt cheap and that's the difference between me having a table saw in the foreseeable future and not, so let's leave that point aside and assume I'm using this saw and not going to be upgrading to a better one for a while yet.

Here we go. I bought a 1500W "Aldi Table Saw" this week (stock left over from when it went on sale last year). Once open the manual and ID plate say it is an Einhell PTS 15/250.

I've been measuring and messing with a few bits and pieces and have determined that with the table top as perfectly level as I can measure, the blade fully raised and perpendicular to the table top, the rear edge of the blade is closer to the left hand mitre track than the front edge is by about 1mm (0.039"). (I've used the same tooth as the reference point for both measurements)

Now, I believe most similar table saws have trunnions which are tweaked to align the blade properly, however this one isn't set up like that.

Here are a few pictures of the insides.

Inside from below the table with the blade at 90 degrees.

Note the 4 large allen head bolts at the top of the box section on the left side of the image.

Also note the black rod running along the centre of the table, this is the pivot for the blade angle.

Inside from below the table with the blade at 22.5 degrees.

Inside from below the table with the blade at 45 degrees.

Angle and blade height mechanisms at 45 degrees.

Angle and blade height mechanisms at 90 degrees.

View through table to blade height pivot.

The bolts you can see immediately below the table surface attach the whole shooting match to the pivot bar you can see running under the table surface in the first three pictures.

The odd looking bits above the height pivot are welded in captive nuts which receive the four large allen bolts you can see in the left hand side of the first picture.

This is about the best I can do on the photo front.

So, any suggestions on how to align this thing?

Again, looking from the front of the machine, the front blade is approximately 1mm (0.039") closer to the left hand mitre track than the rear of the blade.

Measurements taken using the same tooth for both with the blade at full height. Also repeated using other teeth to be sure.

I'm sure many people would question the sense in trying to get a saw like this set up nicely, but I think that once it's done it'll be more than good enough for my purposes (well, once I've stopped the slop in the mitre tracks and made a few extra toys to use with it that is, but I digress...)

I'm looking forwards to your responses.

Cheers folks.