devonwoody

Established Member

Two members this week did a swap with me and I now have a selection of gauges.

I want to make a tool box to hold all of those gauges in one box.

I have calculated that the box will need outside measurements of 410mm long x 295mm x 90mm deep. Using timber that as finished 7.5mm thick.

I sorted this piece of beech, (was bananna shaped.)

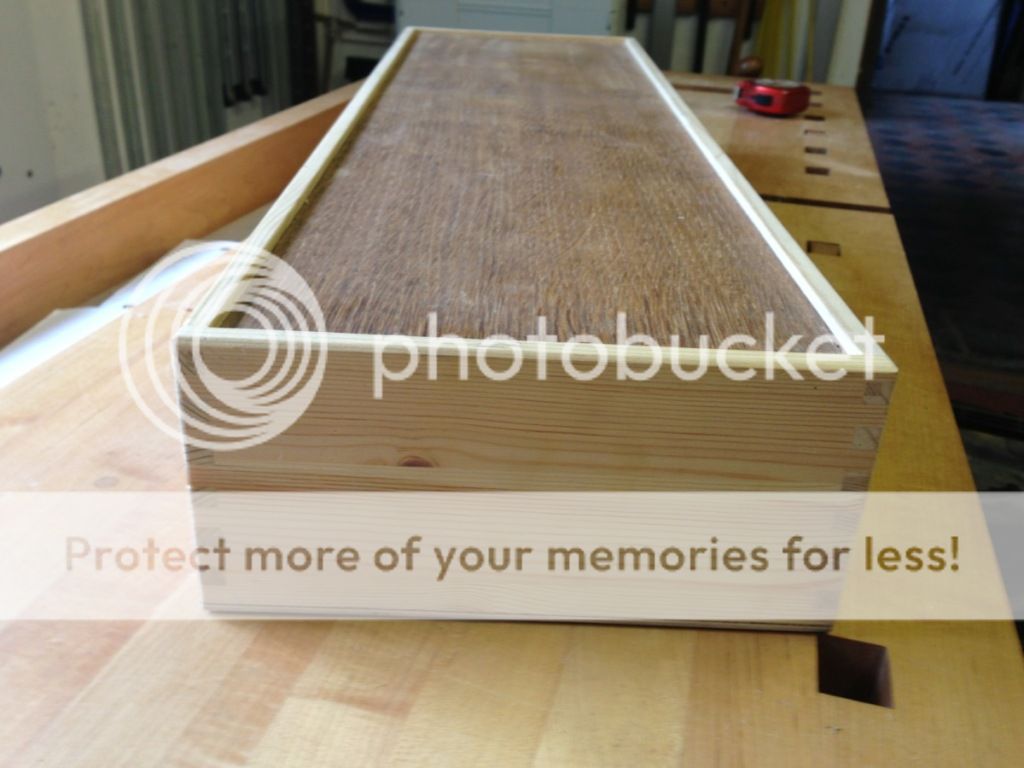

And prepared the four pieces, plus a piece of oak faced ply uncut (4mm thick).

I intend to make the box one piece and then cut off its lid.

The corners are to be dovetailed and this is where I request assistance. I have not done any dovetailing for a while and I know the joints need to accommodate rebates for that ply but have forgotten the technique of allowing for its rebate and to be prepared so the slot does not show eternally.

Can anyone give me the setting up details of the joints so this rebate does not show, using above measurement details?

Edit typo

I want to make a tool box to hold all of those gauges in one box.

I have calculated that the box will need outside measurements of 410mm long x 295mm x 90mm deep. Using timber that as finished 7.5mm thick.

I sorted this piece of beech, (was bananna shaped.)

And prepared the four pieces, plus a piece of oak faced ply uncut (4mm thick).

I intend to make the box one piece and then cut off its lid.

The corners are to be dovetailed and this is where I request assistance. I have not done any dovetailing for a while and I know the joints need to accommodate rebates for that ply but have forgotten the technique of allowing for its rebate and to be prepared so the slot does not show eternally.

Can anyone give me the setting up details of the joints so this rebate does not show, using above measurement details?

Edit typo