Hi all,

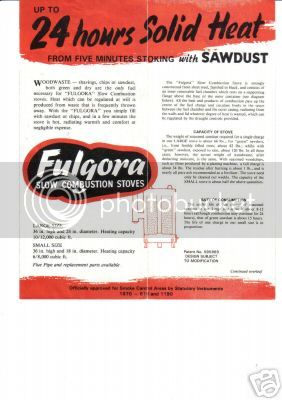

Does anyone have or has had a Fulgora sawdust burning stove? I could do with some advice please;

I just found one in a boot sale and I'm chuffed to bits because once loaded they're supposed to burn unattended for ages; a very nice change to our little wood burner that needs constant attention.

The problem is that I can't get it going, or at least not burning hot enough to warm the workshop nor hot enough to completely burn whatever's coming off the sawdust as after the first go the inside of the burner's coated with a nasty sticky black sludge.

Anyone used/using one of these and can tell me what I'm doing wrong please?

Thanks,

T

Does anyone have or has had a Fulgora sawdust burning stove? I could do with some advice please;

I just found one in a boot sale and I'm chuffed to bits because once loaded they're supposed to burn unattended for ages; a very nice change to our little wood burner that needs constant attention.

The problem is that I can't get it going, or at least not burning hot enough to warm the workshop nor hot enough to completely burn whatever's coming off the sawdust as after the first go the inside of the burner's coated with a nasty sticky black sludge.

Anyone used/using one of these and can tell me what I'm doing wrong please?

Thanks,

T