You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dust hose adaptor problems - be gone!

- Thread starter Farmer Giles

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

pe2dave

Established Member

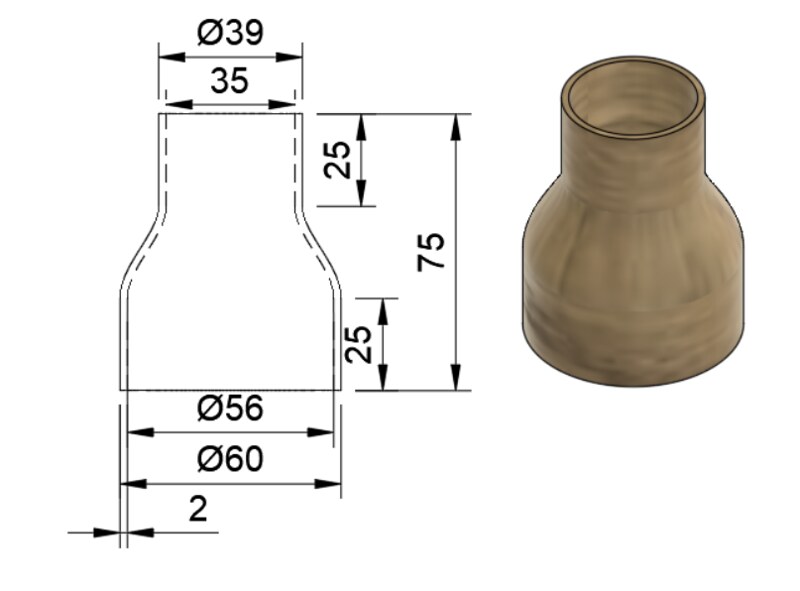

Agree - so the vac goes inside the narrow end, the adapter goes over the cyclone end!

Is it worth leaving a tolerance at that end? Say 56.5 or even 57 - that end will be permanently

connected so even if loose, tape won't hurt? I'll leave that to you!

Thanks.

Is it worth leaving a tolerance at that end? Say 56.5 or even 57 - that end will be permanently

connected so even if loose, tape won't hurt? I'll leave that to you!

Thanks.

DBT85

Established Member

Oh no, I will make it to the dimensions asked for! A 2mm difference in diameter is asking to be clogged up with dust even if most of it ends up in the cyclone bucket. As with all adapters you could heat it up to persuade it to fit. Its heated to 200c to melt the filament anyway so warming it up to make it pliable if needed shouldn't be a problem.Agree - so the vac goes inside the narrow end, the adapter goes over the cyclone end!

Is it worth leaving a tolerance at that end? Say 56.5 or even 57 - that end will be permanently

connected so even if loose, tape won't hurt? I'll leave that to you!

Thanks.

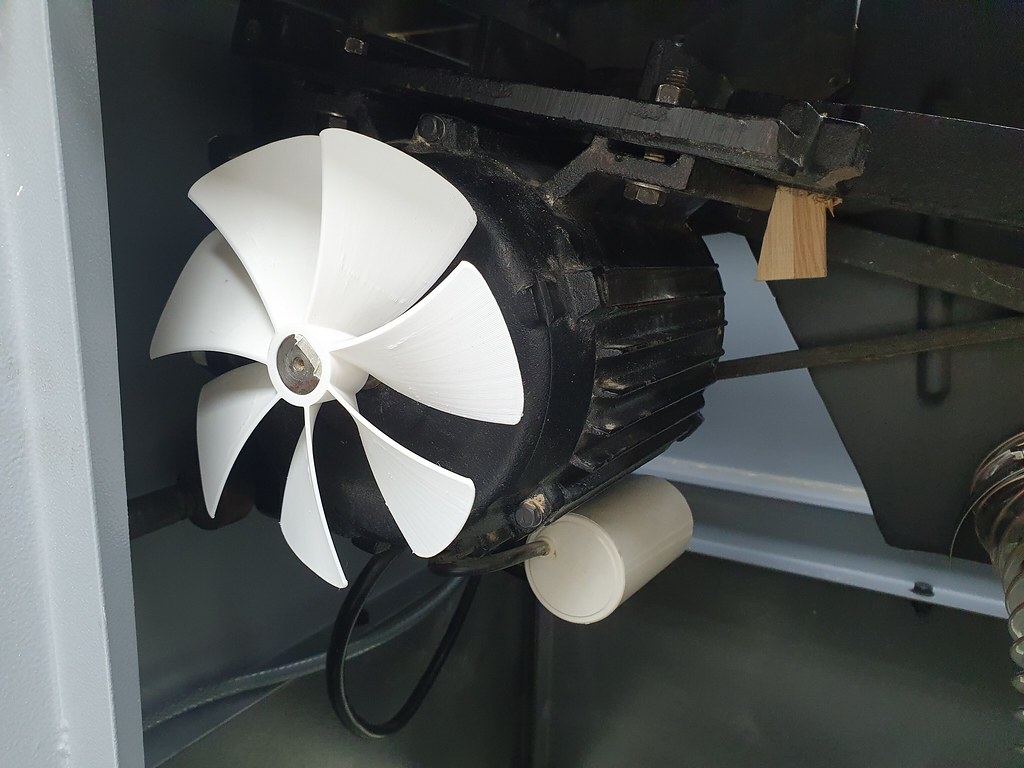

I've some more filament arriving and some larger nozzles as the standard 0.4mm one only allows layer thickness' upto about 0.31mm and for things like a dust connector a larger thickness should be fine as we don't need fine details. Let me get that working and try some test prints. I have to make a new fan for my table saw motor and that'll be something I need to make to a specific diameter to go over the shaft so I can see how accurate it prints to a very specific size.

What I don't want to to start taking money from people for prints that end up 0.3mm too small and all the hassle I could end up with.

pe2dave

Established Member

Thanks. I’ll bow to your experienceOh no, I will make it to the dimensions asked for! A 2mm difference in diameter is asking to be clogged up with dust even if most of it ends up in the cyclone bucket. As with all adapters you could heat it up to persuade it to fit. Its heated to 200c to melt the filament anyway so warming it up to make it pliable if needed shouldn't be a problem.

I've some more filament arriving and some larger nozzles as the standard 0.4mm one only allows layer thickness' upto about 0.31mm and for things like a dust connector a larger thickness should be fine as we don't need fine details. Let me get that working and try some test prints. I have to make a new fan for my table saw motor and that'll be something I need to make to a specific diameter to go over the shaft so I can see how accurate it prints to a very specific size.

What I don't want to to start taking money from people for prints that end up 0.3mm too small and all the hassle I could end up with.

DBT85

Established Member

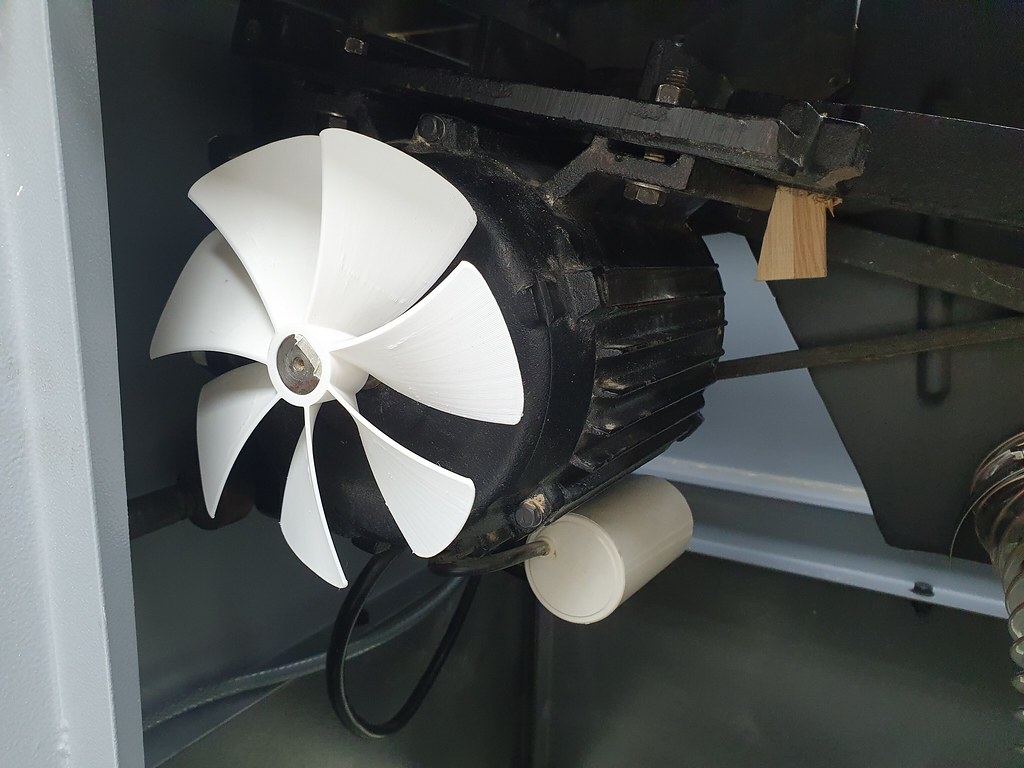

Since this is still the most recent 3d printing thread (maybe we just need a thread all about it?)

my new (old) tablesaw needed a new motor fan. So I drew one up and printed it off. Quite pleased with this one.

my new (old) tablesaw needed a new motor fan. So I drew one up and printed it off. Quite pleased with this one.

HamsterJam

Let’s take it apart to see what’s inside….

Since this is still the most recent 3d printing thread (maybe we just need a thread all about it?)

my new (old) tablesaw needed a new motor fan. So I drew one up and printed it off. Quite pleased with this one.

What design software do you use? I use Tinkercad for simple stuff and RS Designspark Mechanical for more complex shapes.

DBT85

Established Member

ONly ever used Sketchup and then I gave Fusion a try and have been on it since. My brother who could never understand sketchup tried fusion last week and picked it up in ni time at all. No idea why one worked in his head and the other didn't!What design software do you use? I use Tinkercad for simple stuff and RS Designspark Mechanical for more complex shapes.

My printer is running right now. I'm printing a set of quick release heads for the printer  . I'm expecting a laser head for Christmas (I ordered it but it has been confiscated till Christmas) and want to be ready to be able to swap the printer and laser heads out.

. I'm expecting a laser head for Christmas (I ordered it but it has been confiscated till Christmas) and want to be ready to be able to swap the printer and laser heads out.

I inherited mine from my Dad. I bought it as a kit for him about 5 years ago. He used it for quite some time and started doing 3D prints for the company i work for. They upgraded him with a dual head professional unit so i go the one I gave him.

I use it all the time. Many adaptors and repairs have been enabled by the 3D printer. I have a few things on thingverse. I use TurboCAD on the Mac for all the drawing. It's a full on professional package but provided by work as I often draw up the mounts and things we use in test cars to hold cameras and other sensors. With any package there is an initial learning curve but they are pretty straight forward once you get the basics.

My Dad has been retired for years but has a thriving turnover of parts for the model train (live steam) club that he belongs to. You can even print with material that melts ouy of a mold for casting. Brilliant things.

I inherited mine from my Dad. I bought it as a kit for him about 5 years ago. He used it for quite some time and started doing 3D prints for the company i work for. They upgraded him with a dual head professional unit so i go the one I gave him.

I use it all the time. Many adaptors and repairs have been enabled by the 3D printer. I have a few things on thingverse. I use TurboCAD on the Mac for all the drawing. It's a full on professional package but provided by work as I often draw up the mounts and things we use in test cars to hold cameras and other sensors. With any package there is an initial learning curve but they are pretty straight forward once you get the basics.

My Dad has been retired for years but has a thriving turnover of parts for the model train (live steam) club that he belongs to. You can even print with material that melts ouy of a mold for casting. Brilliant things.

Last edited:

DBT85

Established Member

I've not looked at whether the ender 3 pro can deal with a laser too. Not that I have had th etime yet to do some of the prints I want let alone start burning things!

Roberto Flintofski

Established Member

Since this is still the most recent 3d printing thread (maybe we just need a thread all about it?)

my new (old) tablesaw needed a new motor fan. So I drew one up and printed it off. Quite pleased with this one.

Awesome!!!

Similar threads

- Replies

- 10

- Views

- 951

- Replies

- 4

- Views

- 711

- Replies

- 6

- Views

- 969

- Replies

- 0

- Views

- 223