Hi everyone,

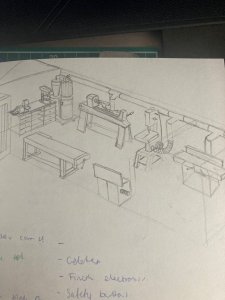

I want to make my dust extraction as efficient as possible over 4 m. I'm struggling to choose between 125mm ducting or 100 ducting.

I've got a 125mm port on the cyclone which has an adaptor on that can take two 100mm.

So, would I need to use 125mm for the main ducting and drop down to 100mm for each machine with flexible pvc pipe for the last meter?

Or do i go with 100m pipe throughout with 100mm flexible pipe for the last meter leading to the machines?

I will use blast gates and it will be rare that more than one machine will be used at any given time.

What do you guys think?

I want to make my dust extraction as efficient as possible over 4 m. I'm struggling to choose between 125mm ducting or 100 ducting.

I've got a 125mm port on the cyclone which has an adaptor on that can take two 100mm.

So, would I need to use 125mm for the main ducting and drop down to 100mm for each machine with flexible pvc pipe for the last meter?

Or do i go with 100m pipe throughout with 100mm flexible pipe for the last meter leading to the machines?

I will use blast gates and it will be rare that more than one machine will be used at any given time.

What do you guys think?