After decades of using metal planes I am starting to appreciate how good a Phillyplane can be but I have found that learning to adjust it precisely is taking a while.

I concluded that I was using too big a hammer since I was always under or overshooting on shaving thickness so I decided to make a posh hammer for my posh plane.

I then remembered from my apprentice days that the right tool for precision positioning on work pieces on milling machines was a dead blow hammer.

The idea is that a non bouncing hammer would give a more precisely controlled blow so this should work for precisely positioning a plane blade.

That led to an article in Model Engineers Workshop on making such a thing from bits of plumbing .

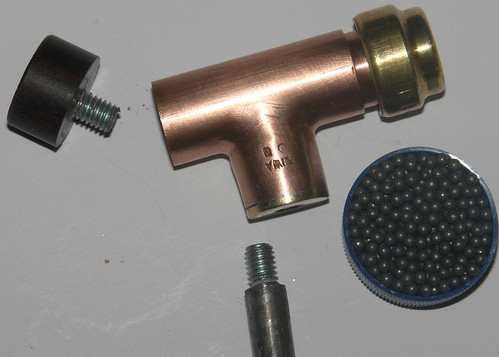

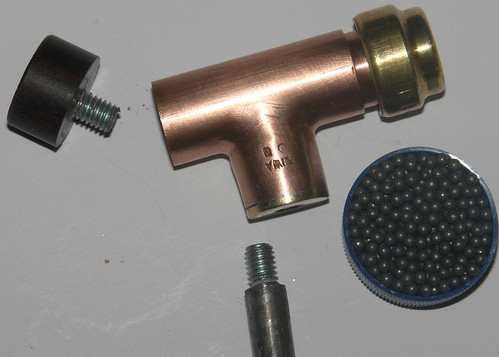

The result after just a few hours work is in the photos.

The construction should be self explanatory and could be simplified by anyone without a lathe, by making wooden plugs for the hammer faces and a wooden handle, to be araldited into the Tee.

I used a brass stop fitting at one end for use on my lathe with a replaceable wooden face at the other end for the plane.

The lead shot to fill the head came fro a local Dive shop.

There must be space in the head for the shot to move a bit or the dead blow effect is lost.

I can now adjust the depth of cut very accurately with no overshoot.

I am afraid that I am now on another slippery wooden slope.

If anyone else is tempted to give this idea a try I would be very interested to get a second opinion

I concluded that I was using too big a hammer since I was always under or overshooting on shaving thickness so I decided to make a posh hammer for my posh plane.

I then remembered from my apprentice days that the right tool for precision positioning on work pieces on milling machines was a dead blow hammer.

The idea is that a non bouncing hammer would give a more precisely controlled blow so this should work for precisely positioning a plane blade.

That led to an article in Model Engineers Workshop on making such a thing from bits of plumbing .

The result after just a few hours work is in the photos.

The construction should be self explanatory and could be simplified by anyone without a lathe, by making wooden plugs for the hammer faces and a wooden handle, to be araldited into the Tee.

I used a brass stop fitting at one end for use on my lathe with a replaceable wooden face at the other end for the plane.

The lead shot to fill the head came fro a local Dive shop.

There must be space in the head for the shot to move a bit or the dead blow effect is lost.

I can now adjust the depth of cut very accurately with no overshoot.

I am afraid that I am now on another slippery wooden slope.

If anyone else is tempted to give this idea a try I would be very interested to get a second opinion