Streepips

Established Member

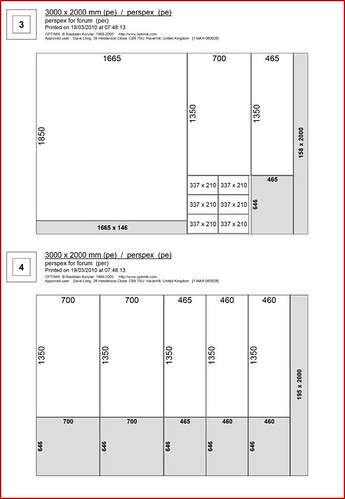

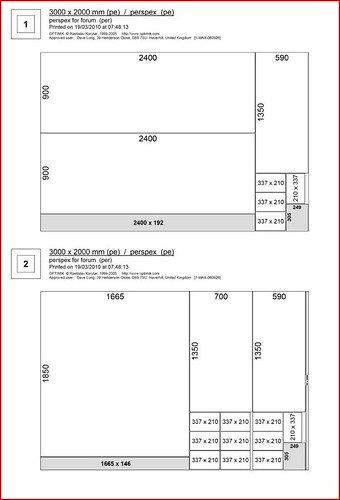

I have always made out cutting lists manually.......... either as a rough guide or even with graph paper and a scale rule and calculator even........Always manage to squeeze every last bit of useful material out of a piece...........

However, just been trying to get a quote for some acrylic/perspex for glazing a greenhouse.. and what I got to 4 sheets of 3mX2m the supplier got to 6 sheets using cutting list software............

I redrew my cutting list. Still 4 sheets. I then downloaded few freebie cutting list progs, all awful to use and did not make efficient use of the boards.......and not even any grain direction to consider.

Second supplier then responded. Quoted using 4 sheets as the amount required........ Spoke with them and asked what cutting list software they used. " Errr We don`t, we do it manually......

Anyone here that uses cutting list software and ever compared it to a manual calculation?

However, just been trying to get a quote for some acrylic/perspex for glazing a greenhouse.. and what I got to 4 sheets of 3mX2m the supplier got to 6 sheets using cutting list software............

I redrew my cutting list. Still 4 sheets. I then downloaded few freebie cutting list progs, all awful to use and did not make efficient use of the boards.......and not even any grain direction to consider.

Second supplier then responded. Quoted using 4 sheets as the amount required........ Spoke with them and asked what cutting list software they used. " Errr We don`t, we do it manually......

Anyone here that uses cutting list software and ever compared it to a manual calculation?