Bkn

Established Member

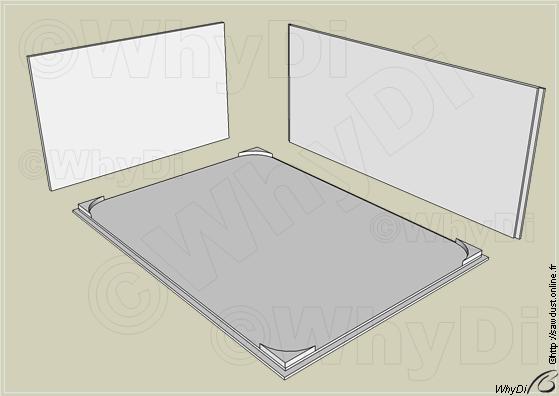

I'm trying to make some small plywood boxes from 6mm plywood. I've been having trouble with cutting it without splintering as well as joining it together. I tried finger joints but that hasn't worked out too well and is quite time consuming + shows the not too attractive end grain.

I was thinking of doing mitre joints but again I'm confused on the best way to go about it. Also I'm aware that with joining end grain to end grain I'll need to prime the edges with a layer of glue and then re-glue.

Here are the tools I have available:

Bandsaw (6tpi blade)

Circular saw (rubbish blade, going to buy a 40tpi freud one I think)

Router table

Crosscut circular saw workstation thing I built

What would be the quickest method that produces decent results?

Thanks

I was thinking of doing mitre joints but again I'm confused on the best way to go about it. Also I'm aware that with joining end grain to end grain I'll need to prime the edges with a layer of glue and then re-glue.

Here are the tools I have available:

Bandsaw (6tpi blade)

Circular saw (rubbish blade, going to buy a 40tpi freud one I think)

Router table

Crosscut circular saw workstation thing I built

What would be the quickest method that produces decent results?

Thanks