Marcjwebb

Established Member

hi guys,

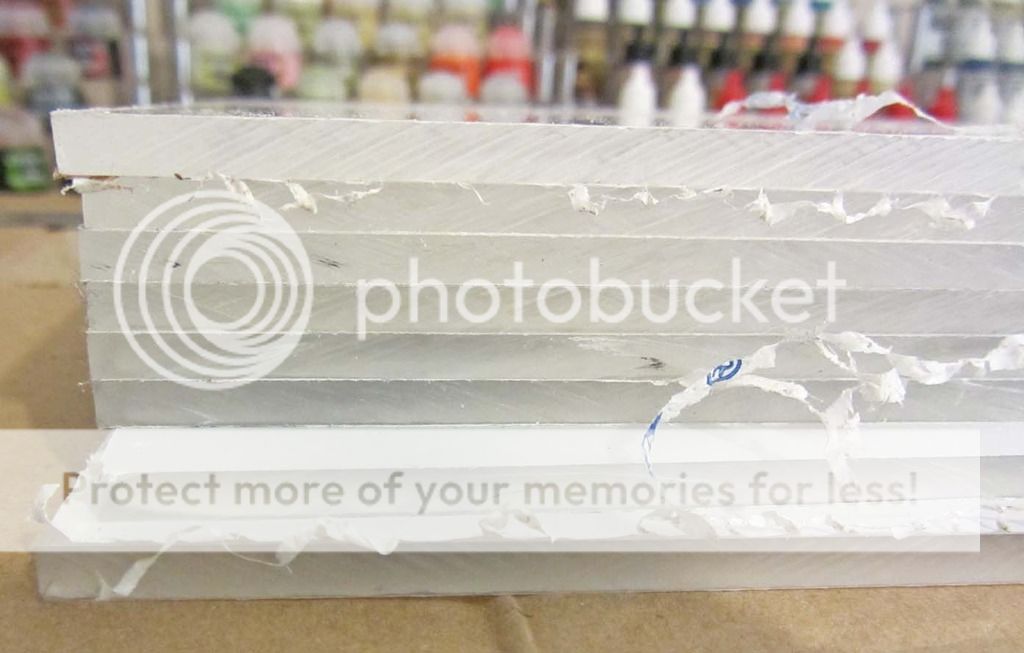

i was wondering if anyone scould give any advice on using a table saw to cut acrylic so that i get nice dead straight cuts

Marc

i was wondering if anyone scould give any advice on using a table saw to cut acrylic so that i get nice dead straight cuts

Marc