J_SAMa

Established Member

HI all,

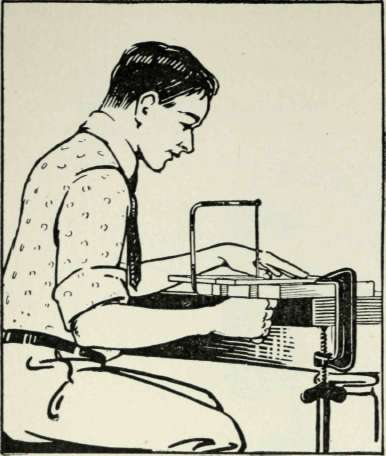

This might be obvious for most of you, but I really have no idea if a coping saw should be used on the push or pull strokes... It came with the blade installed for pull but I couldn't get used to it so I switched it to push. Is there a problem with either?

Also,is it normal for the blade to heat up? My blade was so hot I could smell the wood burning slightly (it was spruce, and honestly spruce burning smelled kinda nice to me ).

).

Sam

This might be obvious for most of you, but I really have no idea if a coping saw should be used on the push or pull strokes... It came with the blade installed for pull but I couldn't get used to it so I switched it to push. Is there a problem with either?

Also,is it normal for the blade to heat up? My blade was so hot I could smell the wood burning slightly (it was spruce, and honestly spruce burning smelled kinda nice to me

Sam