So yesterday i started on some design issues.

I layed it using 2 outer points and a centre point, then used my jack saw to create the curve. Then used some 15mm Ash from another project for the temporary sides to see how things looked.

Then this morning i cut and sanded the mdf template, but something didn't feel right. So i traced round the template, flipped it and compared it to the lines. It was out. After making another one the same way, and checking. This one was worse. The curve was unequal and flatter the one side.

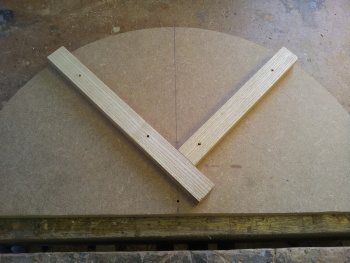

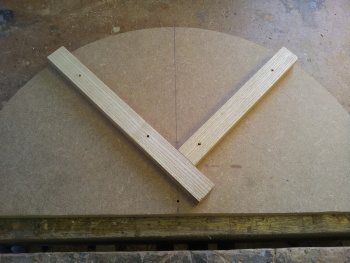

So both were binned and i used my circle cutting jig on the router and cut a big half circle.

I then used a bit of ash off cut to form a fence and screwed it onto the mdf.

This way i was able to rough cut the timber to size, then pop into the jig and route it to get my curve.

After cutting the timber, i thicknessed one piece for the sides / shelf to 15mm and the other piece to 18mm for the base/ top.

Then i used the jig to route out the base/top

The plan was to make the base/top/sides/ shelf look thinner than they are. So starting the the top/ base it used a thumb mould cutter for the top section.

I then switched bits for a round over for the underneath.

Still a load of sanding to do. I was very nervous routing the curved section as i was worried about tear out. :shock: However i think it helped making 0.5mm passes at a time. Yes it took ages, but at least i still have 2 pieces of timber intact. :lol:

Then i squared up the ends on the boards for the sides. Not shown here but you will see later, one board was ripped down to allow jointing at the rear.

I then went on to start working out the dovetails, my first ever dovetails. :shock: A bit chunky, but i have limited small chisels. #-o

After finally deciding on sizes, i started cutting.

This was done with my recently restored DT saw, cuts quite nicely and feels better than hard point tenon saws.

I then cut the waste out with a coping saw, and tried a few of my smaller chisels. Both my 6mm jap and Narex mortice chisels :lol: But a bit bulky for this.

So i have left it for now, until the 6/12mm chisels that i ordered earlier arrive from WSH later this week . .

Just one thing bugging me, for the size of this i'm thinking 18mm is a tad thick for the base / top? Wondering if 15mm would be better and then 12mm for the sides and 10mm for the shelf?