NickP

Member

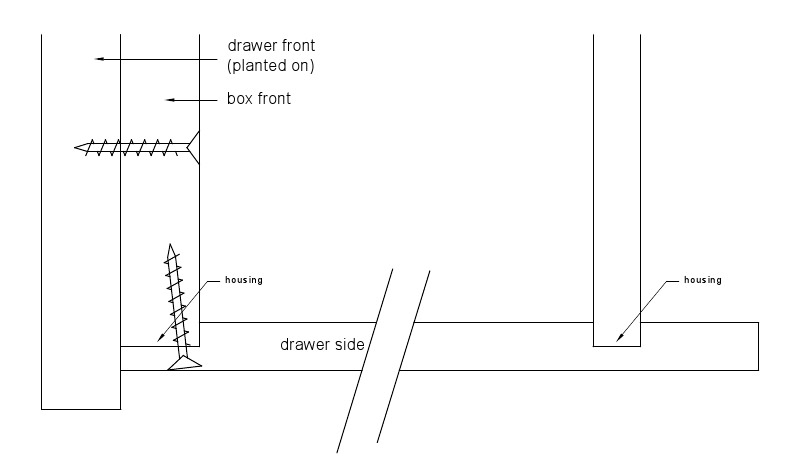

Hi. I'm new to the forum and could do with some advice. I'm trying to build some drawers that will fit into the stairs using the riser as the drawer front. I've looked into runners and been recommended an option from Blum and also spoken to Hafele and been recommended their option. However, I was wondering if anyone could offer advice on the best way to make the actual drawer boxes that doesn't involve a jig.

One person has suggested just making boxes out of MDF, but I was wondering if anyone could suggest a lighter weight option or generally something better?

I'd also appreciate any insight on what runners people here would recommend? Thanks

One person has suggested just making boxes out of MDF, but I was wondering if anyone could suggest a lighter weight option or generally something better?

I'd also appreciate any insight on what runners people here would recommend? Thanks