FrenchIan

Established Member

Gentlemen, may I ask your advice - it may stop me making a silly decision.

I'm going to install a new L-shaped kitchen, with wooden worktops.

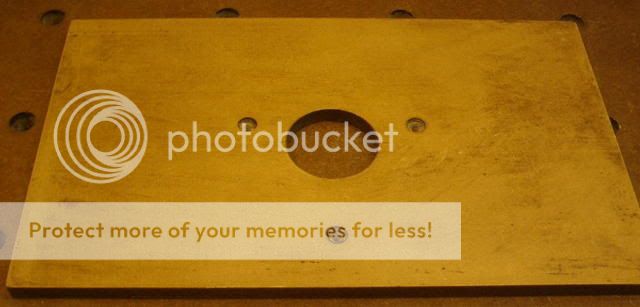

I shouldn't have problems with fitting the units - I've installed several kitchens in my time. The problem lies with joining the two lengths of worktop. To get the almost invisible mitre joint needs a router and jig, and I've never used a router. All the other usual power tools, but not a router.

Normally, I'd call for an experienced joiner to come and do the necessary, but here in France, good tradesmen are scarce (and busy). More to the point, mitred worktops are not, currently, much used, so there may not be that much experience out there.....

Hence, I'm toying with Plan B which is: buy a router, jig and several cutters, and do it myself. It shouldn't be too difficult, I tell myself. I know how to handle powertools, I've fitted loads of worktops, and if I get the two lengths extra long, I can have several shots at the mitre before I cut the other ends to length.

Please, be brutally honest. Has Plan B a cat-in-hell's chance of succeeding?

Thank you

I'm going to install a new L-shaped kitchen, with wooden worktops.

I shouldn't have problems with fitting the units - I've installed several kitchens in my time. The problem lies with joining the two lengths of worktop. To get the almost invisible mitre joint needs a router and jig, and I've never used a router. All the other usual power tools, but not a router.

Normally, I'd call for an experienced joiner to come and do the necessary, but here in France, good tradesmen are scarce (and busy). More to the point, mitred worktops are not, currently, much used, so there may not be that much experience out there.....

Hence, I'm toying with Plan B which is: buy a router, jig and several cutters, and do it myself. It shouldn't be too difficult, I tell myself. I know how to handle powertools, I've fitted loads of worktops, and if I get the two lengths extra long, I can have several shots at the mitre before I cut the other ends to length.

Please, be brutally honest. Has Plan B a cat-in-hell's chance of succeeding?

Thank you