BobWingwang

Established Member

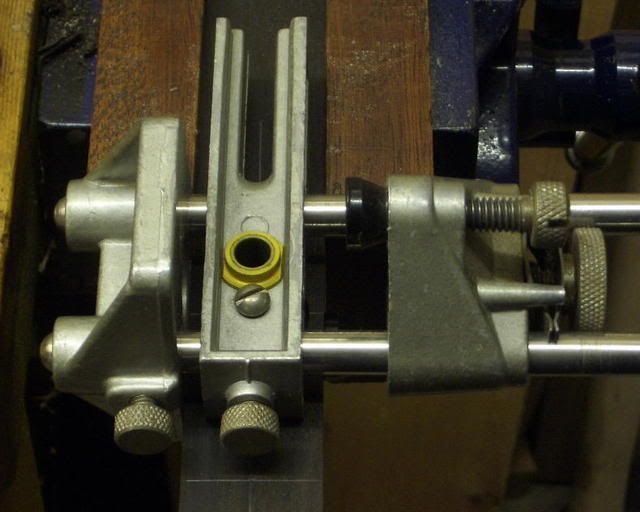

Hello, I want to build some bunk beds (stacking single beds). As much as i hate flat pack furniture, these need to be dismantle-able to enable me to get them in/out of the room. I want to use bolts and barrel nuts (also known as cross dowels), but having tried before, it's tricky to drill perfectly straight, aligned holes to joint these components,

I've found a jig in America (woodpecker cross dowel jig). These use imperial drill bits and bolts/cross dowels. I'd prefer an imperial version, but i'm having no luck finding one. Has anybody seen one of these in the UK. If i knew what it was called it'd be easier to Google!

Thanks, Adrian.

I've found a jig in America (woodpecker cross dowel jig). These use imperial drill bits and bolts/cross dowels. I'd prefer an imperial version, but i'm having no luck finding one. Has anybody seen one of these in the UK. If i knew what it was called it'd be easier to Google!

Thanks, Adrian.