PhilC

Established Member

Hi, does anyone know what the minimum height cut I can do at 45degress should be?

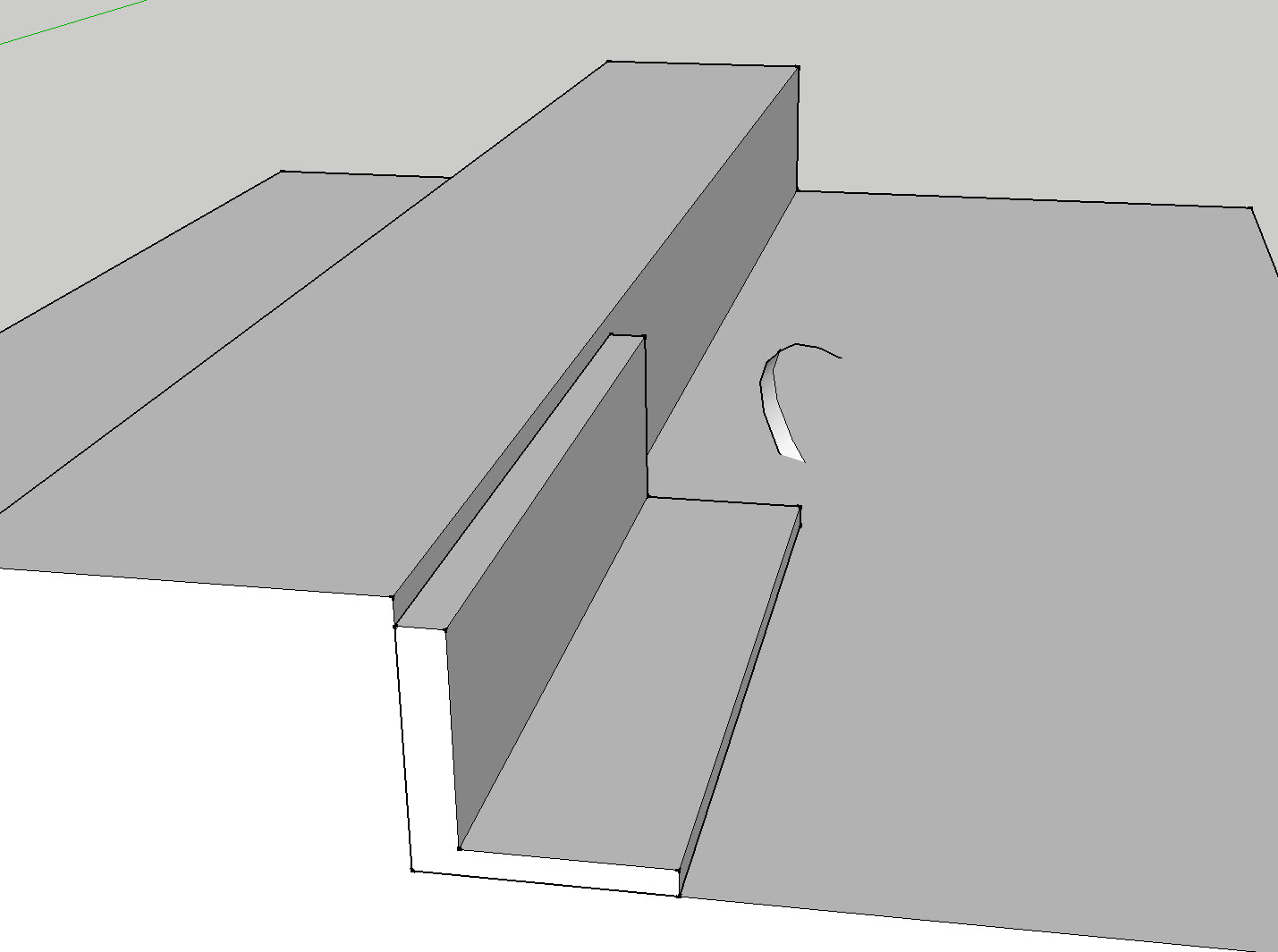

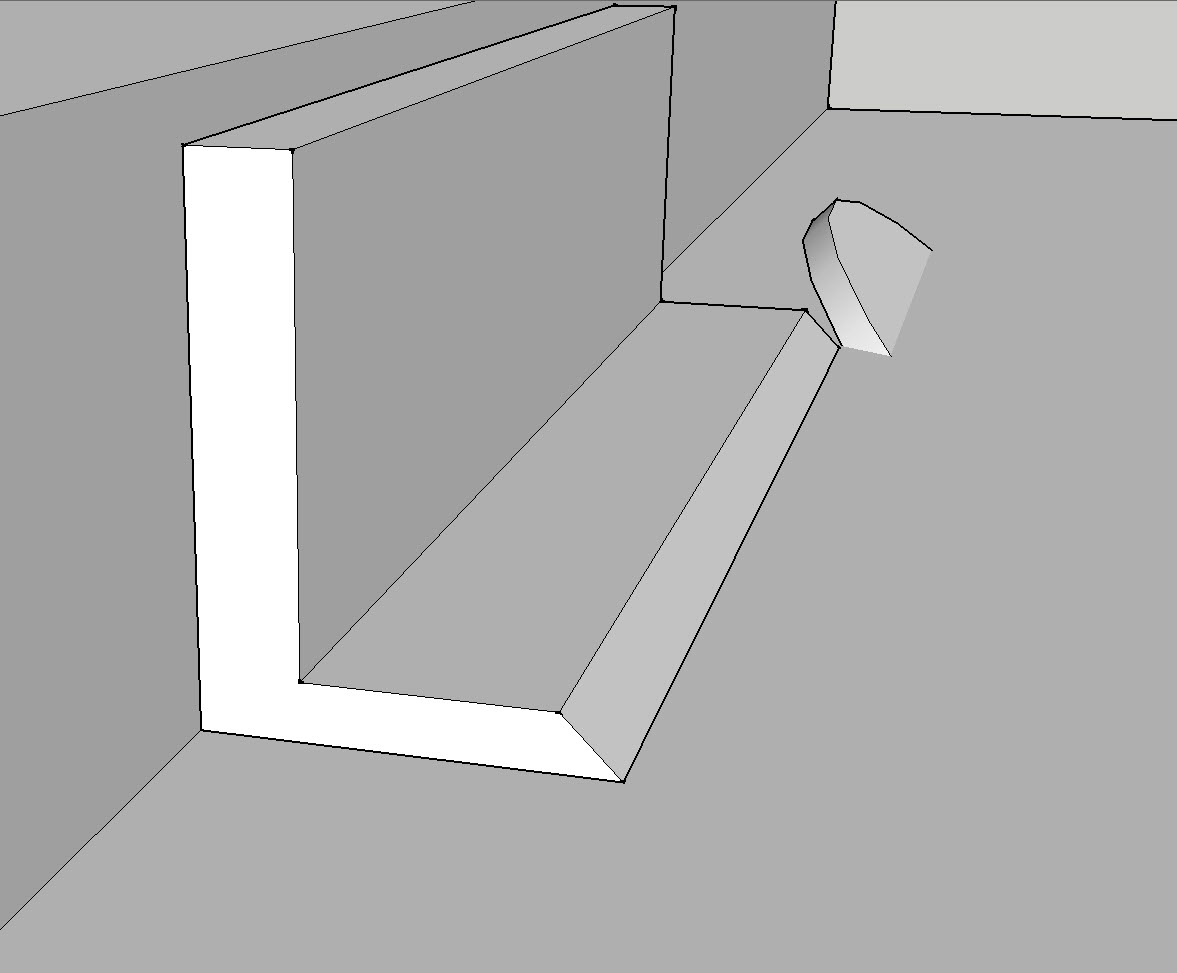

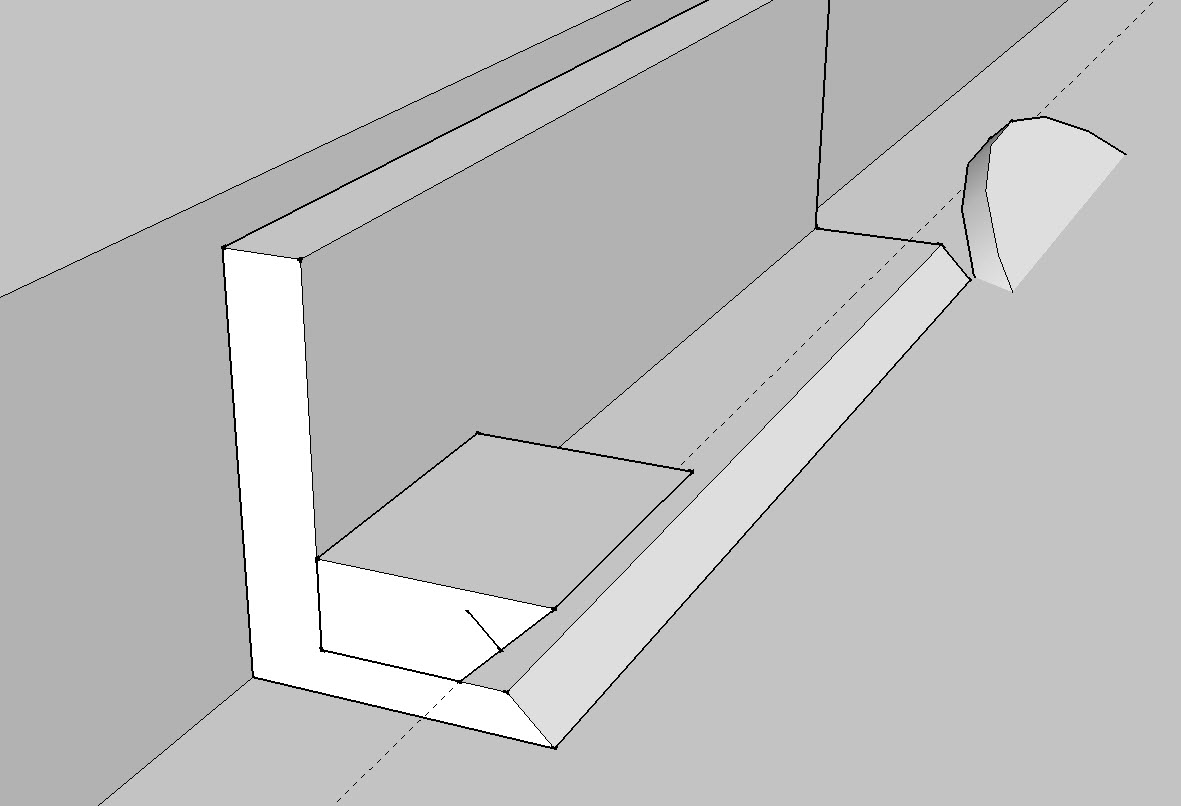

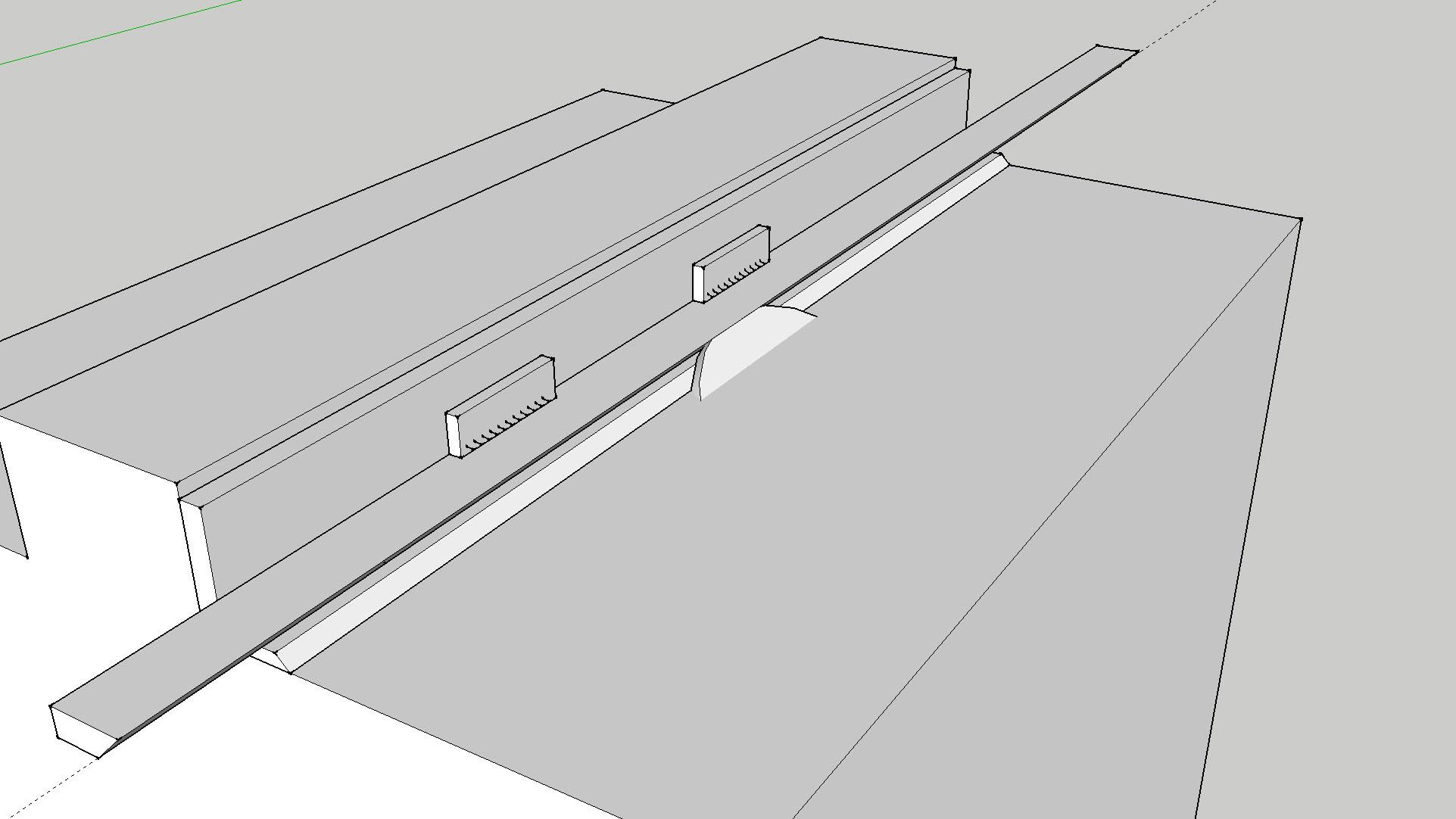

I have a new (well not new but not set up yet TS 250) table saw and I want to try and do something like this

But when I try and tilt the blade over at low heights it touches the table top slot side.

But when I try and tilt the blade over at low heights it touches the table top slot side.

Am I trying to do something that can't be done on the ts250?

I have a new (well not new but not set up yet TS 250) table saw and I want to try and do something like this

Am I trying to do something that can't be done on the ts250?