As a point of interest, what percentage of you use a spindle moulder? Many folk on here have saw benches and planer/thicknessers and some even have bandsaws and/or lathes, but I rarely see people discussing the spindle. Vote today and make your voice heard......

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are you a spindle moulder user?

- Thread starter Scrit

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

If I'm working solid timber then I much prefer the spindle, gives a better finish, makes less noise than a router and I can extract the dust a lot more efficently than a router table. Just a shame TCT tooling is so pricy as the standard HSS ones don't like MDF too much  As mine is part of a combi machine I can also make use of the sliding carrage.

As mine is part of a combi machine I can also make use of the sliding carrage.

Jason

Jason

tim

Established Member

I don't have one - Can't really afford the space and if I'm honest they scare the bejesus out of me. When I replace my TS and move to a bigger workshop then I might consider one as part of a combi.

Having built up quite a router cutter selection its also difficult to contemplate the duplication at this stage. That said, I have a lot of tapes and videos but it didn't stop me getting a CD/ DVD player!

Cheers

Tim

Having built up quite a router cutter selection its also difficult to contemplate the duplication at this stage. That said, I have a lot of tapes and videos but it didn't stop me getting a CD/ DVD player!

Cheers

Tim

woodshavings

Established Member

LIke Jason, mine is part of my Combi (Maxi). I dont use so much since I built my Norm Style Router table fitted with a Triton, although for long mouldings and heavy work, I still prefer it.

John

John

paisawood

Established Member

I've had a Felder Saw/spindle combination for a couple of years and am now using the Spindle moulder more and more. I started fairly slowly, initially using it just for rebates but now use it for making mouldings, edging boards, raising panels, template moulding and grooving. It is also my preferred way of cutting tenons. I also use it with a 60mm sanding spindle for smoothing bandsaw cut edges.

Making full use of the guards is essential, and a fair bit of thought has to be given to workholding and safe working practices. I haven't had any worrying incidents yet but am very aware of potential safety issues.

I would say in retrospect that a bit of initial training would have been a good idea, but the opportunity never seemed to arise!

Overall, I'm very happy with the moulder.

David

Making full use of the guards is essential, and a fair bit of thought has to be given to workholding and safe working practices. I haven't had any worrying incidents yet but am very aware of potential safety issues.

I would say in retrospect that a bit of initial training would have been a good idea, but the opportunity never seemed to arise!

Overall, I'm very happy with the moulder.

David

RogerS

Established Member

tim":31g32xru said:When I replace my TS and move to a bigger workshop then I might consider one as part of a combi.

Tim

Any idea which one you'd go for, Tim?

Roger

I must say I find it curious that some people find the spindle moulder "scary". When I first used one square cutter blocks were legal (only just) and they really were scary, partly because the cast/forged cutters weighed a bit more than a bullet, but could certainly reach a deadly velocity if the bolt was loose and they came off. Nice thing about them, though was that you could attach 4 or even 6 cutters to a block to make a compound shape. The other thing which was legal then was the French cutter, a flat piece of steel held in a slot through the spindle with the profile gound at one end and a relief at the other (they only cut at one end) - they could come loose and rattle or worse they did occasionally break or bend, but I used ti be able to grind and sharpen one in 5 to 10 minutes which meant they were great for one-offs, although a couple of hundred feet and they were blunt! Fortunately (at least on safety grounds) they are both no more, and nowadays we are required to use safety blocks with either Shaw guards or a power feeder on spindle moulders. All of this means that the spindle's reputation as number finger remover is thankfully declining, although I'd agree with the comment that training is really a pre-requisite to safe and effective use.

A good book if you are using spindles ame wany a reference is Eric Stephenson's "Spindle Moulder Handbook" (ISBN 0-85442-031-2 publ. Stobart-Davies circa £17.00), alternatively there is a good if less comprehensive section in F E Sherlock' s "MACHINE WOODWORKING TECHNOLOGY For Hand Woodworkers" (same web page: ISBN 0-85542-041-X publ. Stobart-Davies £6.95).

The only thing I've used a spindle for which is still a bit scary is ring fence work - kind of like using a guide bearing bit in a router in a table, the main difference being that your block can normally take a 40 or 50mm high "bite" and is 100 to 125mm in diameter - and unlike a router you generally do the full cut in one pass. Even there providing you've got a good heavy "sled" which keeps your fingers away from the cutterblock and holds the work firmly, and you are using a proper bonnet guard, it normally isn't too scary - just heavy work if you are doing a lot of them.

As a point of nomenclature, the spindle moulder is often referred to in English as a "spindle" whereas in the USA it is called a "shaper". Moulder in the UK means one of these:-

Above: Vonnegut 8in 4/S moulder circa 1948. These were a 1930s design many of which sutvived in use into the 1970s and 1980s

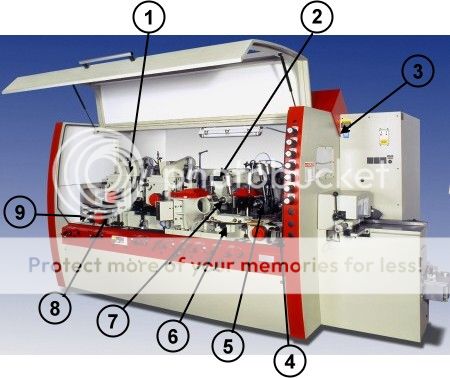

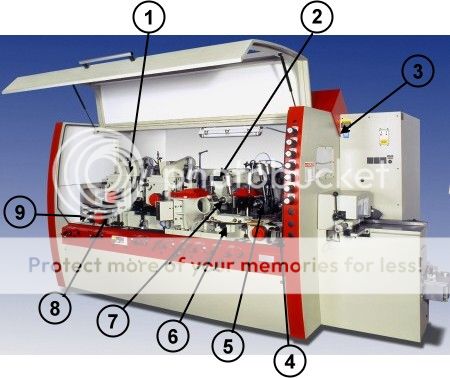

Below: Modern Weinig 4/S moulder

A four-sided moulder (or 4/S in shorthand) - completely different beast with very different tooling.

Scrit

A good book if you are using spindles ame wany a reference is Eric Stephenson's "Spindle Moulder Handbook" (ISBN 0-85442-031-2 publ. Stobart-Davies circa £17.00), alternatively there is a good if less comprehensive section in F E Sherlock' s "MACHINE WOODWORKING TECHNOLOGY For Hand Woodworkers" (same web page: ISBN 0-85542-041-X publ. Stobart-Davies £6.95).

The only thing I've used a spindle for which is still a bit scary is ring fence work - kind of like using a guide bearing bit in a router in a table, the main difference being that your block can normally take a 40 or 50mm high "bite" and is 100 to 125mm in diameter - and unlike a router you generally do the full cut in one pass. Even there providing you've got a good heavy "sled" which keeps your fingers away from the cutterblock and holds the work firmly, and you are using a proper bonnet guard, it normally isn't too scary - just heavy work if you are doing a lot of them.

As a point of nomenclature, the spindle moulder is often referred to in English as a "spindle" whereas in the USA it is called a "shaper". Moulder in the UK means one of these:-

Above: Vonnegut 8in 4/S moulder circa 1948. These were a 1930s design many of which sutvived in use into the 1970s and 1980s

Below: Modern Weinig 4/S moulder

A four-sided moulder (or 4/S in shorthand) - completely different beast with very different tooling.

Scrit

Scott

Established Member

- Joined

- 18 Oct 2004

- Messages

- 846

- Reaction score

- 0

Scrit":18hkxoom said:I must say I find it curious that some people find the spindle moulder "scary".

Just ignorance and urban legend in my case I suppose. As I say I've never tried one and don't have the training or the opportunity to do so although my French next-door neighbour has one of those French cutter jobbies that looks like Stevie Wonder sharpened it with an angle grinder!! That doesn't help with my overall impression of the things!

A

Anonymous

Guest

You must enter a message when posting

tim

Established Member

Roger Sinden":227ejxzj said:tim":227ejxzj said:When I replace my TS and move to a bigger workshop then I might consider one as part of a combi.

Tim

Any idea which one you'd go for, Tim?

Roger

No - not even looked at options. No point really until nearer the time.

Cheers

Tim

AndyBoyd

Established Member

I use the Sheppach one and after quite a few training session my Hans Koot my guru, I agree they are quite safe and easy to use.

The seat frames and the legs on my lovechairs wered one using the shaper (and a little on the router table). My favourite thing to do is tdeep template work (seats on Lovechairs) using the follower bearing.

I often add the router collet option and use it instead of my router table, as it's much quieter

The seat frames and the legs on my lovechairs wered one using the shaper (and a little on the router table). My favourite thing to do is tdeep template work (seats on Lovechairs) using the follower bearing.

I often add the router collet option and use it instead of my router table, as it's much quieter

Freetochat

Established Member

I use a spindle, and have followed guidance from a video (Roy Sutton) and a couple of books. I wouldn't mind a day or two of instructions, but it is not easy to come by.

I have a Sheppach combi which I find easier, quicker and cheaper (cutters) to use than a router

How's that work Andy?

John

I often add the router collet option

How's that work Andy?

John

Similar threads

- Replies

- 0

- Views

- 226

- Replies

- 14

- Views

- 970