Not just to to demonstrate that the so called 'pros' don't know it all ](*,) ..or very much at all in my case,

I thought I'd put this up for debate.

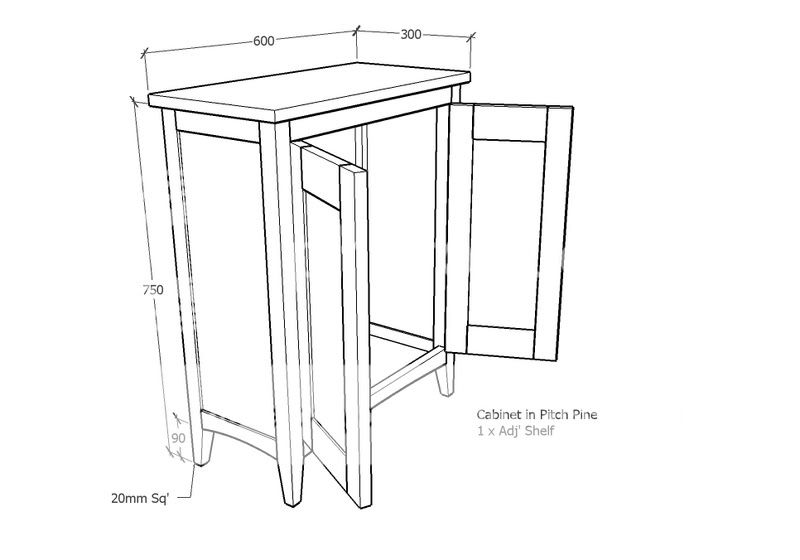

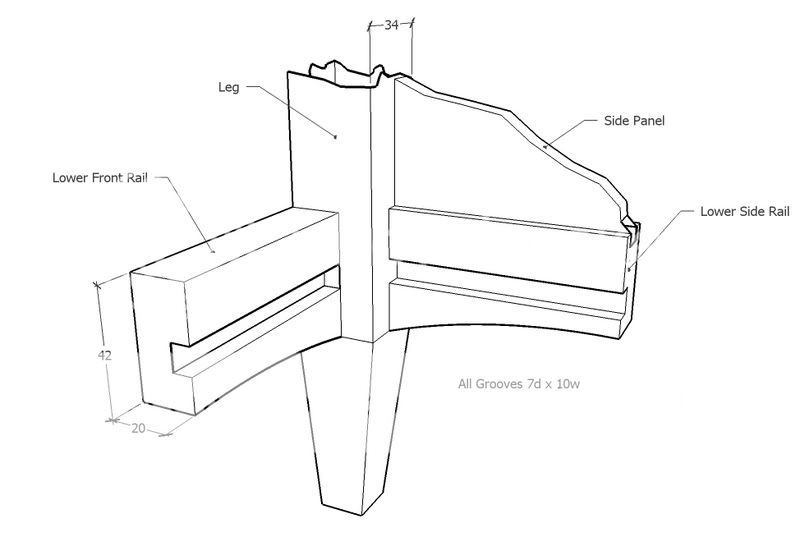

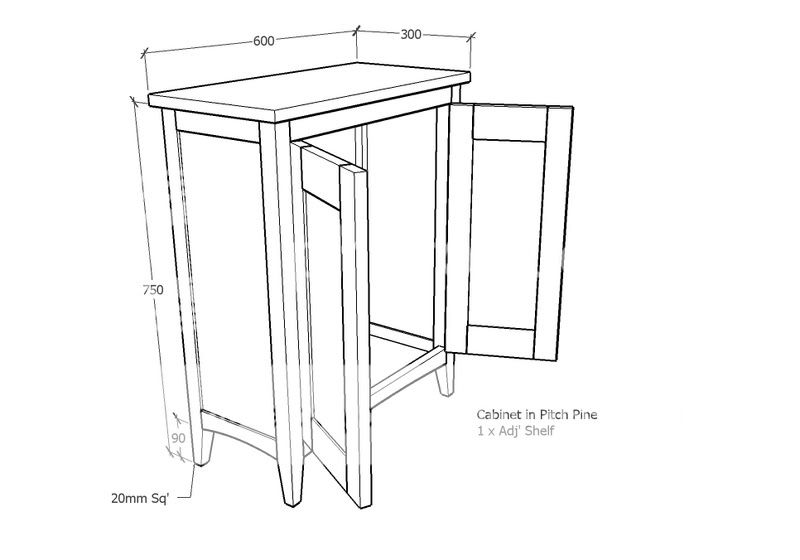

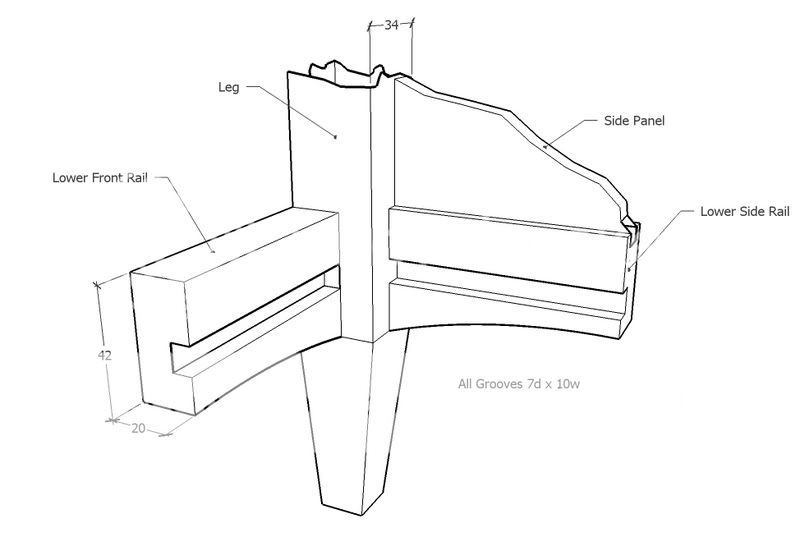

It's a cabinet I'm building for an Artist who's exhibiting at Chelsea Flower Show (...typical Artist, no money involved - just the possible kudos of my having made something that's exhibited there!)....anyway, I want the rails to be flush with the legs and all materials to be solid wood.I may embarass myself here, but I just can't figure out a good way of fitting the base. Below is a sectional view from inside the cabinet, last time I made something similar I cut the base to go round the legs, but that was a lot smaller.

If I cut the groove into the legs as well that's going to make the legs weak, if I chop a square out of the corners of the base then, if it contracts it'll show a gap and if it it expands it will foul the legs and something will have to give eventually.

I have a feeling that I've over designed myself here. Go on guys - do a bit of lateral thinking and tell me what I'm missing!

Chris.

I thought I'd put this up for debate.

It's a cabinet I'm building for an Artist who's exhibiting at Chelsea Flower Show (...typical Artist, no money involved - just the possible kudos of my having made something that's exhibited there!)....anyway, I want the rails to be flush with the legs and all materials to be solid wood.I may embarass myself here, but I just can't figure out a good way of fitting the base. Below is a sectional view from inside the cabinet, last time I made something similar I cut the base to go round the legs, but that was a lot smaller.

If I cut the groove into the legs as well that's going to make the legs weak, if I chop a square out of the corners of the base then, if it contracts it'll show a gap and if it it expands it will foul the legs and something will have to give eventually.

I have a feeling that I've over designed myself here. Go on guys - do a bit of lateral thinking and tell me what I'm missing!

Chris.