I think you probably already knew (but didn't say) that there is a router sled for Makita rails. It's not very expensive and it uses the trammel/fence holes on the router baseplate, so anything with the same spacing and rail sizes will probably fit. I suspect that includes Trend and DW routers, but I haven't tried. Additionally the Makita sled MIGHT fit Festool rails (they differ from Makita ones on the 'back' edge away from the blade). I haven't got one, as the occasions I'd need it are very few.

I have found out that the same "micro-adjustable) router fence casting is used on a wide range of router brands, implying there is a de-facto standard - same bars spaced the same distance apart. I have one of these fences (it came with my Trend T11) that I can also use on my much smaller Bosch routers. It has fittings for both sizes of bars on the two different spacings. So I'd guess if you get the Makita sled you may find it works with a range of routers, even though they don't advertise this.

The thing most likely to be different between router manufacturers, however, is the height of the bar holes of the router, above its baseplate. This doesn't matter for a router fence (probably why they can get away with all using the same casting for the fence!). It would matter when using a sled running on tracksaw rails.

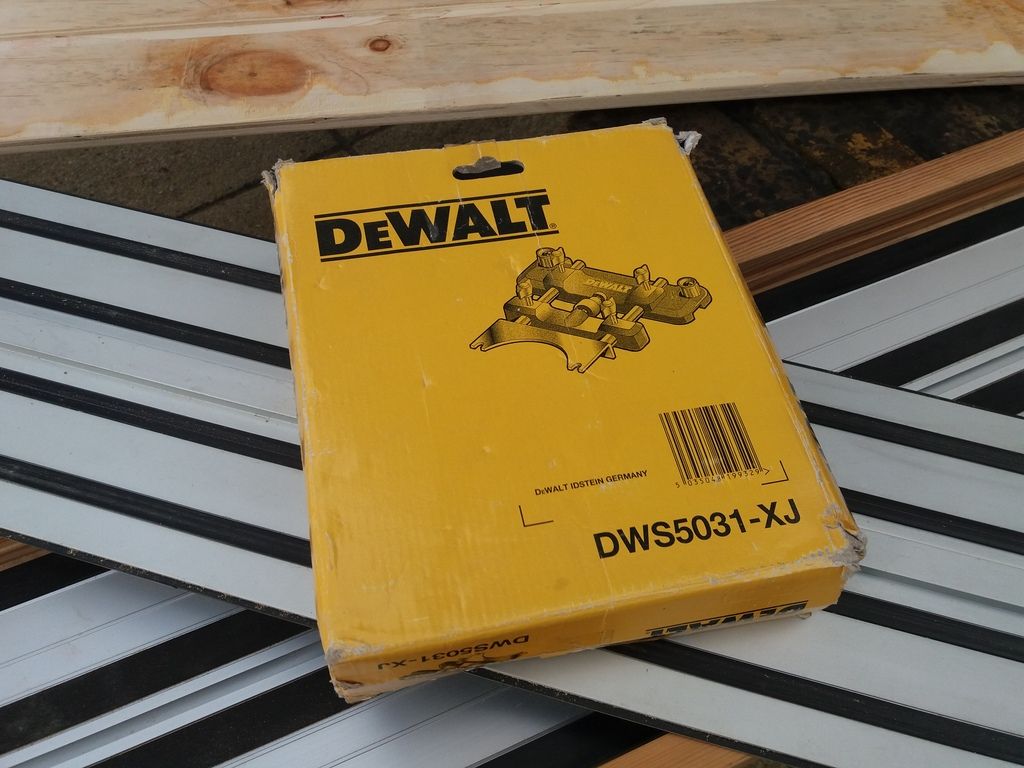

I don't know how similar DW rails are to Festookl and Makita - you'd have to check.

OK, after saying all that, it's worth pointing out that you could make your own router sled for tracksaw rails pretty easily. All they are in essence is a block shaped to match the profile of the rail (near the back), with a pair of matching holes, into which the trammel/fence bars for the router can fit.

IIRC, they are 10mm bars usually for most 1/2" routers, and 8mm for the smaller sizes (my Bosch POF 500/600s, Trend T4, and possibly T5, etc.). So all you really need to do is cut slots in a (longer=better) hardwood block to the right profile, and two parallel 10mm holes at right-angles to the profile. It has to be one of the easiest jigs ever! If you don't have enough "meat" in a block of wood as-is, consider using a slab of MFC under the router base to lif it slightly, and allow your slider to be correspondingly thicker.

One important reason why router sleds might not be popular is the need for offset measuring and marking. One of the best things in use about track saws is that you cut right on the edge of the rubber strip. If I understand the Makita sled, you'd have to use offset marking at best, and you'd be foolish to run the router base along the rubber strip anyway, because it would drag and scuff.

It all sounds like a lot of fuss and bother, compared to just clamping a batten to the workpiece and running along that, or using the router table (moving the work instead).

I can see that a well-constructed sled would stop the cutter wandering in either direction (against a batten, you really need to cut in one direction only - the other will pull the router away from it's correct line), but there will be a big twisting force on the sled in use, because the router cutter is a long way from the axis along which the sled slides (what a mouthful!). That will make it tend to jam, and to skip daintily along the track rather than slide smoothy.

To sum all that up:

You probably can use a Makita router sled with other routers, and possibly with other brands of track, but you probably don't want to, (a) because you can cheaply make your own (just as good, or even better), and (b) because the whole idea sounds good but actually doesn't work very well in practice, compared to just a batten or one of those simple clamp-on guide bars.

I've got one of those. I winced at the price when I bought it years ago (Trend stuff is never cheap!), but I've used it again and again - takes seconds to set up and it's really easy to use.

E.