devonwoody

Established Member

Is this going to be a box to far?

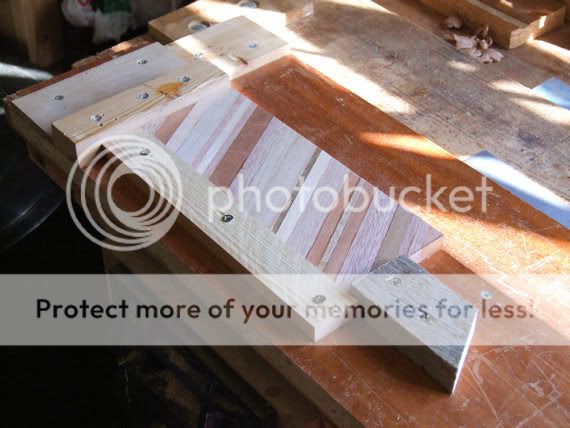

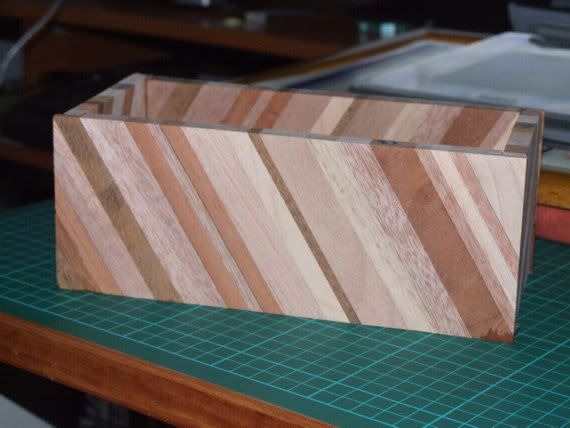

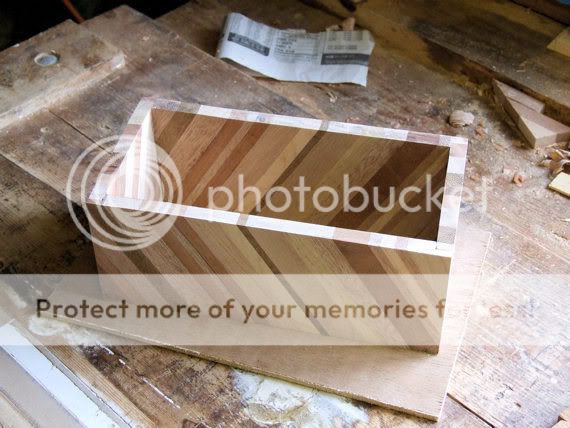

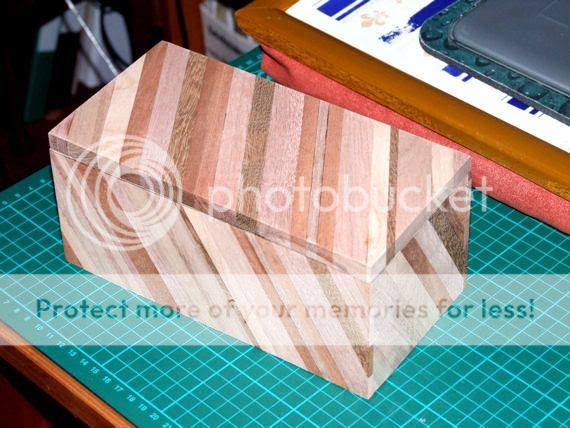

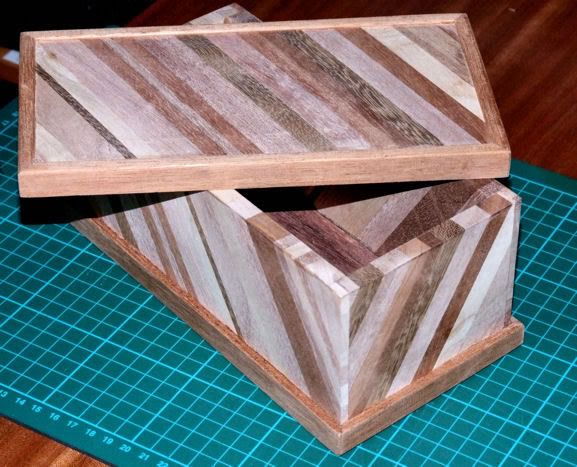

I have caught the laminating bug, so I have placed a couple of boards on my bench to represent the area I have got to amass for this new box.

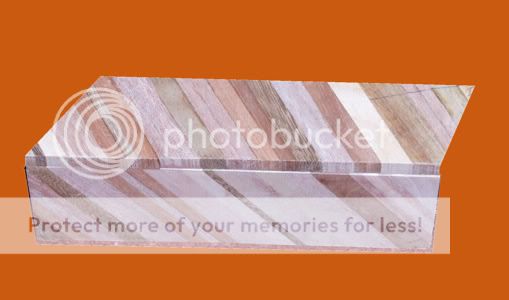

The area I am aiming for is 2 pieces of 9"x3" and 2 pieces of 4"x3" and one piece (for the lid) of 9"x 5"

The scrap pieces laid over former size boards.

The progress first day preparing strips to make the diagonals.

haven't decided yet how I shall joint the corners when above boards have been sized, any suggestions?

I have caught the laminating bug, so I have placed a couple of boards on my bench to represent the area I have got to amass for this new box.

The area I am aiming for is 2 pieces of 9"x3" and 2 pieces of 4"x3" and one piece (for the lid) of 9"x 5"

The scrap pieces laid over former size boards.

The progress first day preparing strips to make the diagonals.

haven't decided yet how I shall joint the corners when above boards have been sized, any suggestions?