Joe90

Established Member

Hi

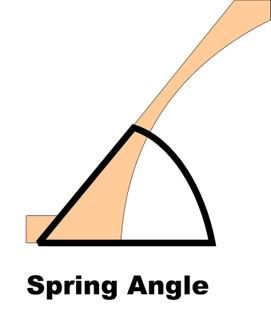

As the title says... why does my Makita SCMS have the angle 31.6 degrees specially marked:?: I have never known the answer....

1 point for the first correct answer!

Cheers

Joe

As the title says... why does my Makita SCMS have the angle 31.6 degrees specially marked:?: I have never known the answer....

1 point for the first correct answer!

Cheers

Joe